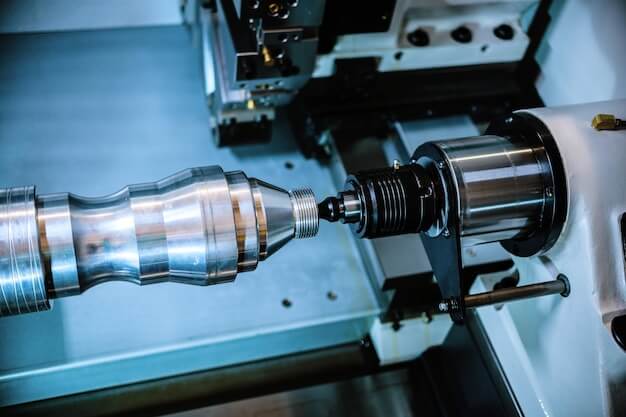

Challenges posed by material ductility in CNC machining

Understanding Material Ductility in CNC Machining In the realm of Computer Numerical Control (CNC) machining, where precision and accuracy are paramount, material ductility represents a significant factor influencing the quality and efficiency of the manufacturing process. The intrinsic ability of metals to deform under tensile stress without fracturing is what defines their ductility. Grasping the […]

Analysis of processing difficulty of different materials in CNC processing

Introduction to CNC Processing and Material Selection CNC processing, a cornerstone of modern manufacturing, stands for Computer Numerical Control machining, a method where pre-programmed software commands the movement of factory tools and machinery. The selection of materials in CNC machining is critical; it not only influences the final product’s attributes but also affects the ease […]

Sheet Metal Fabrication for Automotive Industry

Introduction to Sheet Metal Fabrication in the Automotive Industry Sheet metal fabrication is a cornerstone process in the automotive industry, essential for constructing vehicle frames, bodies, and components. It involves cutting, bending, and assembling sheets of metal to create precise shapes and structures tailored for specific functions within a car. The significance of this technique […]

Micro Injection Molding: Principle, Benefits, and Applications

Introduction to Micro Injection Molding Micro injection molding is a specialized form of manufacturing that enables the production of small and intricate plastic parts with precision. The process involves injecting thermoplastic or thermosetting polymers into a mold at high pressure, which results in the material conforming to the shape of the mold cavity. Unlike traditional […]

Here are 7 tips for reducing costs in CNC machining.

Introduction to Cost Reduction in CNC Machining CNC machining stands as a pivotal manufacturing process where computer-guided machinery produces complex parts with precision. In an industrial landscape where the push for cost-effectiveness parallels demands for high quality, strategies to trim down expenditures without compromising on output are essential. The upcoming tips highlight how manufacturers can […]

Pewter: What It Is, Properties, Importance, Uses, and Advantages

Definition and Brief History of Pewter Pewter is a malleable metal alloy traditionally composed primarily of tin, with small amounts of copper and antimony added for strength and durability. Historically, lead was also included in the mix, but due to its toxicity, it has been largely phased out in modern pewter formulations. Originating over two […]

Titanium is used in the production of medical and aerospace instruments.

Unique Properties of Titanium Titanium, a lustrous transition metal with a low density and high strength, stands out for its remarkable resistance to corrosion and ability to withstand extreme temperatures. These unique properties make it an ideal material for demanding engineering applications, particularly in the medical and aerospace sectors. Its biological inertness allows for its […]

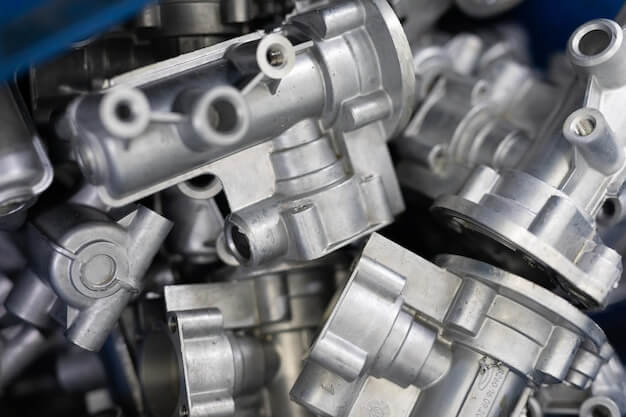

Exploring the World of Non-Ferrous Metals: Characteristics, Applications, and Innovations

Introduction to Non-Ferrous Metals Non-ferrous metals, distinguished by their lack of iron content, are highly valued for their versatility and distinct properties such as resistance to corrosion, high conductivity, and lightweight. These characteristics make them indispensable across a wide array of industries including aerospace, automotive, electronics, and construction. For example, aluminum’s combination of low density […]

Different types of casting

Introduction to Casting in Manufacturing Casting is a foundational manufacturing process wherein molten material—often metal—is poured into a pre-shaped mold and allowed to solidify, forming a replica of the mold’s internal geometry. This technique enables the production of complex shapes that would be challenging or uneconomical to achieve through other methods. The versatility of casting […]

Alloy steel vs stainless steel

Introduction to Alloy and Stainless Steels Alloys are a blend of metals where the main component is enhanced by additional elements to improve its properties. The distinction between alloy steel and stainless steel is fundamental in engineering and manufacturing industries, as both types possess distinct characteristics that make them suitable for different applications. Alloy steel […]

What Is Tack Welding? Understanding Its Purpose and Importance

Introduction to Tack Welding Tack welding is a preliminary welding process wherein short, intermittent welds are used to hold metal components together before the final welding. This technique is akin to using basting stitches in sewing or temporary pins in woodworking; it maintains alignment and positioning during the construction phase. It’s particularly crucial when dealing […]

What’s Non-Ferrous Metal? In-Depth Overview

Introduction to Non-Ferrous Metals Non-ferrous metals are a broad category of metallic elements and alloys that do not contain iron in appreciable amounts. The absence of iron signifies that they are typically more resistant to corrosion and rust, which makes them ideally suited for applications where longevity and minimal maintenance are desirable. These metals are […]