The Advantages of Using Magnesium Alloys in Lightweight CNC Machined Components

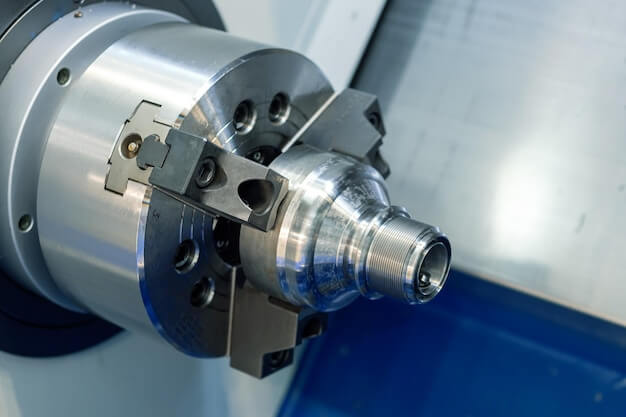

Introduction: CNC Machining and Magnesium Alloys In the manufacturing industry, Computer Numerical Control (CNC) machining is a vital process used to create components with extreme precision. This innovative tech involves dictating the movements of machinery using computer software, which ensures highly accurate outputs in a much shorter timeframe. On another note, magnesium alloys play an […]

Strategies for Managing Material Waste in CNC Machining Operations for Sustainability

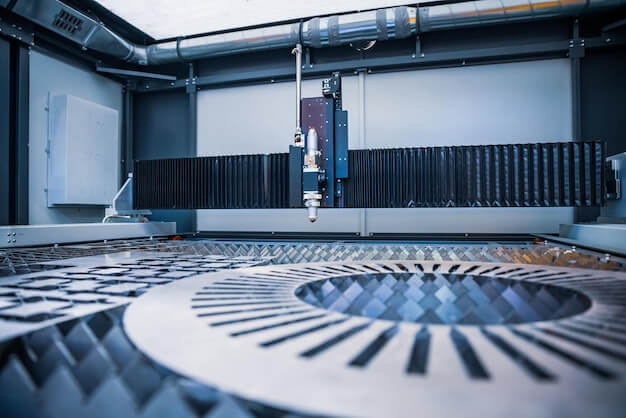

Introduction to CNC Machining Operations and Sustainability CNC (Computerised Numerical Control) machining operates by controlling machine tools through perfectly programmed computers. This automated process uses pre-programmed software which guides factory machinery and tools to conduct an array of tasks with accuracy and speed, adding efficiency and productivity enhancements to the manufacturing sector. However, during these […]

Tool Steel in CNC Machining: D2 vs. A2 – A Comparison of Durability and Performance

CNC Machining and the Importance of Tool Steel Computer Numerical Control, commonly referred to as CNC machining, is a high-precision manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It plays an instrumental role in creating complex three-dimensional shapes that would otherwise be impossible or highly tedious via manual manipulation. […]

CNC Machining for Extreme Environments: Material Selection for Heat and Corrosion Resistance

CNC Machining and Material Selection in Extreme Environments The process of Computer Numerical Control (CNC) machining involves a computer-aided design to control the complex movement of machinery. This technology is utilized across various industries, transforming raw material into custom-made parts with high precision. It’s important to note that selecting appropriate materials for CNC machining becomes […]

Material Fatigue in CNC Machining: Steel vs. Aluminum Lifespan Analysis

Introduction to CNC Machining and Material Fatigue CNC or Computer Numerical Control machining is a manufacturing technique in which pre-programmed computer software controls the movement of factory tools and machinery. This method significantly helps streamline complicated production processes and render high precision results, thanks to its automated nature. An often overlooked but crucial aspect of […]

CNC Machining Precision: How Material Choice Affects Tolerance and Accuracy

Introduction to CNC Machining CNC Machining stands for Computer Numerical Control Machining, a cornerstone in modern manufacturing. This process uses computer-controlled machines to achieve high precision and accuracy in creating parts. It’s pivotal for industries where precision is paramount, such as aerospace, automotive, and medical devices. The essence of CNC machining lies in its ability […]

Material Versatility in CNC Machining: From Metals to Polymers and Beyond

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to automate the manipulation of materials, ranging from metals to polymers and beyond, showcasing an impressive versatility. Key to its importance is the ability to produce […]

Thermal Management in CNC Machining: Material Selection for Heat Dissipation

Introduction to CNC Machining and Thermal Management CNC (Computer Numerical Control) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated production of complex parts. Its importance is underscored by its widespread application across various industries, from aerospace to automotive. At the heart of CNC machining’s efficiency and precision lies effective thermal […]

Achieving Precision in CNC Machining: The Importance of Material Uniformity and Selection

CNC Machining and the Significance of Precision CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process is used to control a range of complex machinery, from grinders and lathes to mills and routers. The precision of CNC machining is critical for several reasons: 1. […]

Cost-Effective CNC Machining: Evaluating Material Choices for Budget-Conscious Projects

Introduction to Cost-Effective CNC Machining CNC (Computer Numerically Controlled) machining is an advanced manufacturing process that uses programmed software to control tools and machinery. In the contemporary production sector, this technology plays a significant role thanks to its ability to create intricate parts with high precision and consistency. For budget-conscious projects, cost-effectiveness becomes paramount. The […]

High-Speed vs. Conventional CNC Milling: Material and Application Considerations

CNC Milling: An Overview of High-Speed vs Conventional Methods Computer Numerical Control (CNC) milling is a machining process that plays an invaluable role in producing intricate parts for various applications. Through the use of computer systems to control and manipulate machine tools, CNC milling allows for precision accuracy in creating complex 3D shapes from solid […]

Bridging the Gap with CNC Machining: Composites vs. Metals in Aerospace Applications

The Aerospace Industry and the Significance of Component Materials In the aerospace industry, the selection of materials plays a significant role in achieving efficiency while maintaining safety standards. The components’ materials need to withstand harsh environmental conditions like extreme temperatures, pressures, and high-speed movements. Consequently, metals have traditionally been preferred due to their durability and […]