The Engineer’s Choice: Titanium Grade 5 vs. Grade 23 for CNC Medical Implants

CNC Medical Implants: Material Choices and their Significance Computer Numerical Control (CNC) medical implants are an integral part of modern healthcare, designed with precision to replace missing or damaged body parts. With the unprecedented advancements in technology, customizing these implants for every patient’s unique needs has become possible, ensuring better health outcomes and faster recovery […]

The Ultimate Guide to Sheet Metal Materials: Aluminum vs. Galvanized Steel

Introduction: A Brief Overview of Sheet Metal Materials in Manufacturing In the wide world of manufacturing, sheet metal materials play a pivotal role. They serve as critical components in various industries including automotive, aerospace, and construction. The two primary types of these metals often used are Aluminum and Galvanized Steel due to their unique properties. […]

Metal 3D Printing Showdown: Titanium vs. Stainless Steel

Introduction to 3D Printing and the Importance of Material Choice The rapid proliferation of three-dimensional (3D) printing technology has imbued various industries with transformative prospects. In essence, 3D printing is a form of additive manufacturing that involves layer-by-layer creation of physical objects from digital models. Such a technique affords significant time, cost savings, and customizable […]

Carbon Fiber vs. Fiberglass: Strength, Cost, and Application Showdown

Introduction to Carbon Fiber and Fiberglass In the world of synthetic materials, carbon fiber and fiberglass are two distinct but essential elements which have become indispensable across various industries. Carbon fiber is a high-strength material made from thin strands of crystalline filaments that significantly reduce weight while maintaining strength. It excels in situations where lightness, […]

Comparative Analysis of Machinability: Nickel Alloys vs. Stainless Steel in CNC Processes

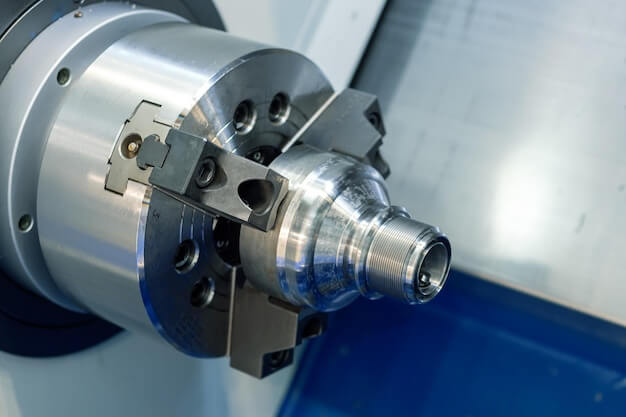

Introduction to CNC Processes and Materials The Computer Numerical Control (CNC) process is a predominant method in the manufacturing industry, enabling the machining of complex parts with high precision. It comprises systems that utilize computer programming inputs to control machinery for various operations like drilling, cutting, or milling. This technique ensures efficient production by eliminating […]

Eco-Friendly CNC Machining: Sustainable Materials and Practices

Eco-Friendly CNC Machining: An Introduction CNC (Computer Numerical Control) machining is a manufacturing process that commands the movement of factory machinery and tools using pre-programmed computer software, ensuring precise design production. This technique plays an indispensable role in modern manufacturing due to its accuracy, consistency, scalability, and versatility. Despite these advantages, however, traditional CNC machining […]

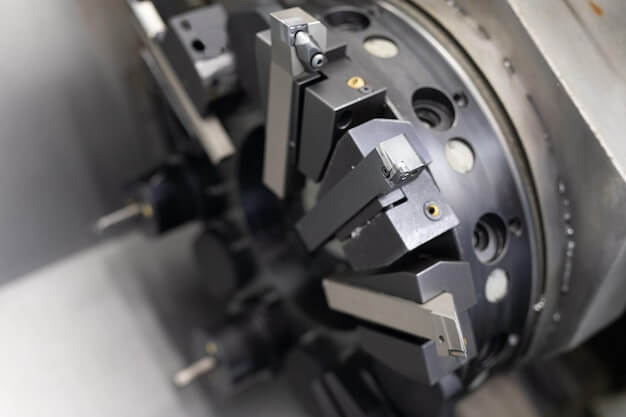

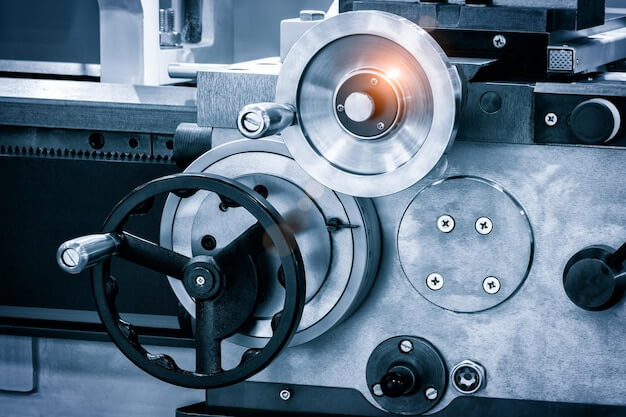

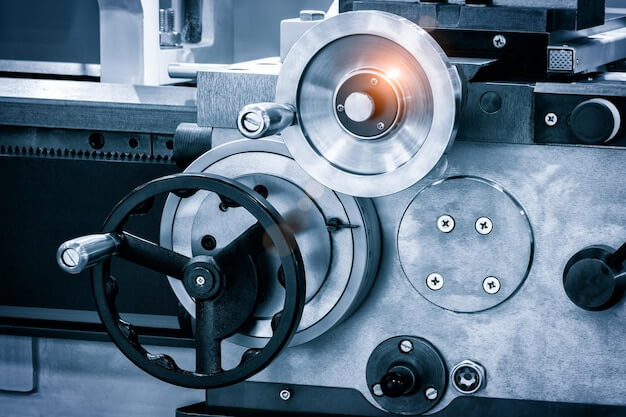

Understanding CNC Machining: An In-Depth GuideThe Art of Precision: Exploring CNC Milling Processes

Understanding CNC Machining: An Integral Process in Modern Manufacturing CNC (Computer Numerical Control) machining is a critical process in today’s advanced manufacturing landscape. It refers to the automated control of machining tools such as mills, lathes, routers, and grinders by means of computer programming. This process has revolutionized production lines across various industries due to […]

The Role of Surface Finishes in CNC Machining: Comparing Methods for Different Materials

Introduction to CNC Machining and Surface Finishes CNC machining, or Computer Numerical Control machining, is a pivotal process in modern manufacturing that leverages computerised controls to operate and manipulate machine tools. It allows for the precise construction of complex three-dimensional shapes with unparalleled accuracy. In this system, surface finishing plays an integral role as it […]

The Essential Guide to Selecting the Right Metal for CNC Machining: Stainless Steel vs. Carbon Steel

Introduction to CNC Machining and Metals In the realm of creation and manufacturing, Computerized Numerical Control (CNC) machining serves as a critical tool. It is an advanced system involving the use of pre-programmed computer software to control the movement of factory machinery and tools for precise parts production. Two primary metals utilized in this process […]

Innovations in CNC Machining: High-Temperature Alloys vs. Traditional Materials

CNC Machining: Its Techniques and Significance in Material Selection Computer Numerical Control (CNC) machining, a fabrication method extensively employed within the engineering realm, manipulates pre-programmed computer software to regulate factory tools and equipment. It simplifies complex manual operations by transforming them into facile steps implemented by machine-driven instructions automatically. A pivotal determinant of successful CNC […]

Brass vs. Copper in Custom Parts Manufacturing: A Comparative Analysis

Introduction to the Importance and Uses of Metals in Custom Parts Manufacturing In custom parts manufacturing, metals play a significant role due to their robustness, versatility, and adaptability. Frequent application involves producing machinery parts, hardware items, instruments, and countless other products. As different metals possess varied properties, understanding these differences is essential for optimizing output […]

The Advantages of Titanium Alloys in Aerospace Manufacturing

The Advantages of Titanium Alloys in Aerospace Manufacturing Aerospace manufacturing is an industry involved with the design and production of both aircraft and spacecraft. It encompasses two main sectors, aeronautics and astronautics, each having their own unique challenges that demand precise engineering solutions. One such solution often carried out in this dynamic field involves the […]