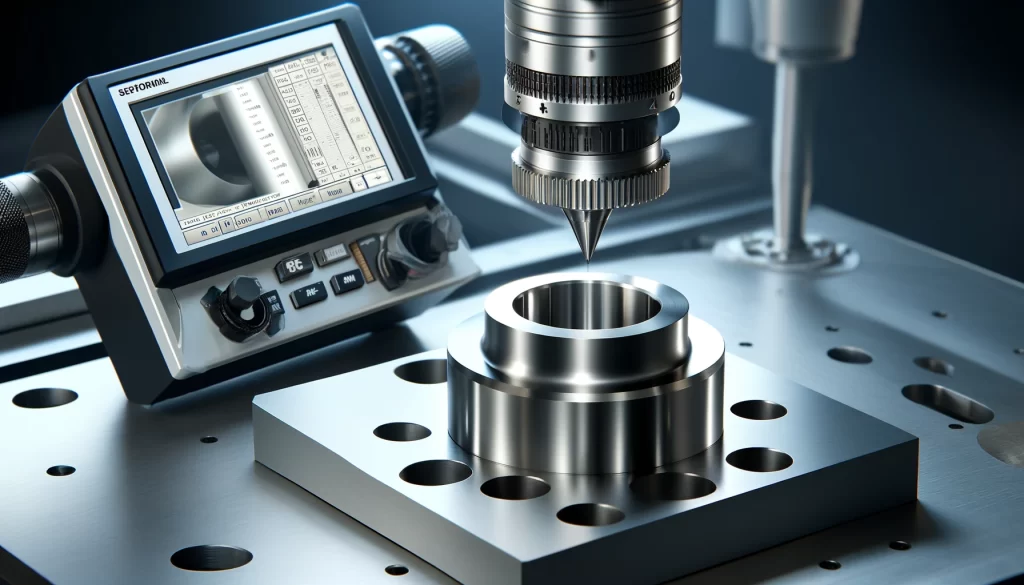

What Factors Affect the Precision of CNC Machined Stainless Steel Flanges?

What Role Does Material Selection Play in the Precision of CNC Machined Stainless Steel Flanges? The choice of stainless steel grade significantly affects the machining process and the quality of the final flange. Stainless steels like 304 and 316 are commonly used due to their corrosion resistance and machinability. However, differences in their composition, such […]

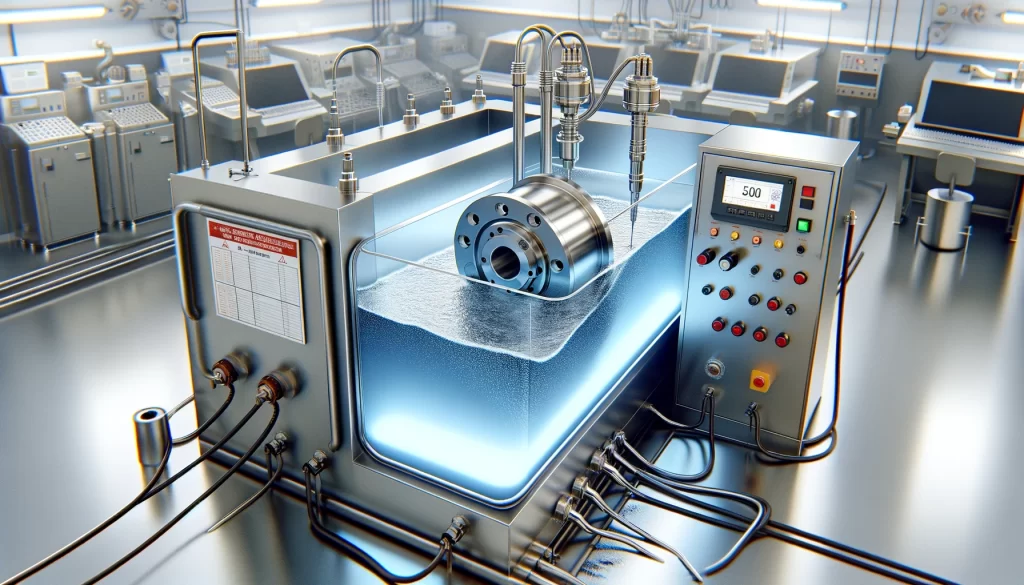

How Does Electropolishing Enhance the Properties of CNC Machined Stainless Steel Components?

The Significance of Electropolishing in Modern Manufacturing Electropolishing stands as a pivotal process in the realm of advanced manufacturing, especially for industries that demand precision and aesthetic quality in their components. This technique, often employed post-CNC machining, not only enhances the visual appeal of stainless steel parts but also significantly boosts their performance characteristics. By […]

How Can Electropolishing Improve the Surface Finish of CNC Machined Stainless Steel?

The Role of Electropolishing in Enhancing CNC Machined Surfaces Electropolishing is a critical finishing process used extensively in the fabrication of stainless steel components. This process not only enhances the aesthetic appearance of the parts but also significantly improves their functional properties. In industries where precision and cleanliness are paramount—such as in medical devices, food […]

How Can Surface Finish Be Optimized in CNC Machining of Stainless Steel?

What Factors Affect Surface Finish in CNC Machining of Stainless Steel? The quality of the surface finish in CNC machining stainless steel is influenced by a variety of factors ranging from machine settings to the physical properties of the material: Detailed Factors Table: Factor Impact on Surface Finish Recommended Practices Material Hardness Increases tool wear […]

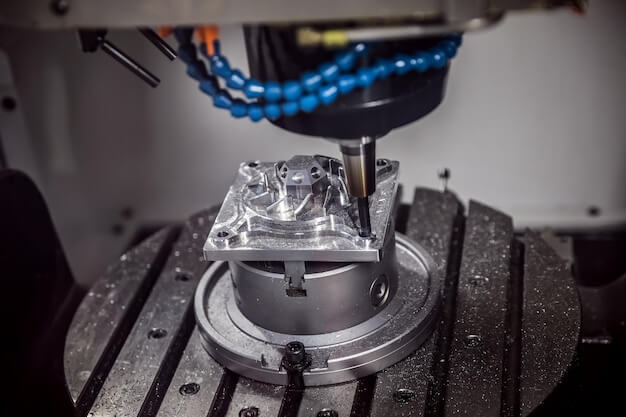

What Key Factors Should Be Considered When Choosing a Precision CNC Machining Partner to Optimize Stainless Steel Parts for Food Automation Machinery?

The Importance of Precision CNC Machining in Stainless Steel Parts for Food Automation Machinery Precision CNC machining plays a pivotal role in the production of stainless steel parts for food automation machinery. The rigorous demands of the food industry, including strict hygiene standards and the need for durable equipment, make the choice of a CNC […]

What Service and Support Capabilities Should a Supplier of Precision CNC Machined Bronze Parts Have?

The Specific Needs for CNC Machining of Bronze Parts Bronze is a preferred material for components that require high strength, excellent corrosion resistance, and superior fatigue endurance. However, the specific needs for CNC machining bronze stem from its varied alloy compositions, which can include elements like tin, aluminum, and nickel. Each alloy type presents different […]

What Criteria Define the Best CNC Machining Service for Precision Copper Manufacturing?

Understanding Precision CNC Machining for Copper The precision CNC machining process requires a deep understanding of the properties of copper. Copper is known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance, but it is also a soft metal that poses unique challenges for CNC machining. Effective machining of copper requires specialized tooling and […]

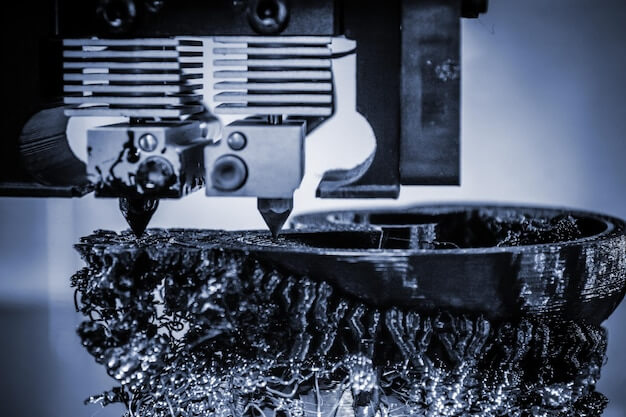

Precision CNC Machining of Stainless Steel: Innovations and Best Practices in Aerospace Machining

Introduction: Precision CNC Machining and the Use of Stainless Steel Precision Computer Numerical Control (CNC) machining, a vital technology within the manufacturing industry, uses pre-programmed software to guide machinery towards the production of complex 3D parts with precision. This innovative technique plays an instrumental role in numerous industries, such as aerospace, automotive, and medical equipment […]

How to Find the Most Suitable Precision CNC Machining Supplier for Stainless Steel Parts in Food Automation Machinery?

The Importance of Precision CNC Machining in the Global Food Industry Precision CNC (Computer Numerical Control) machining has become indispensable in the manufacturing of stainless steel parts for food automation machinery. The global food industry relies heavily on these machines to ensure efficiency, reliability, and compliance with stringent hygiene standards. Precision CNC machining enables the […]

Stainless Steel Machining for Medical Devices: Ensuring Precision and Compliance with CNC Techniques

Introduction to Stainless Steel Machining in the Medical Devices Industry The medical devices industry has made significant strides in operational efficiency and patient safety, largely due to advancements in stainless steel machining. This involves the computerized shaping of stainless steel into components needed for critical equipment like surgical tools and implants, using Computer Numerical Control […]

5-Axis CNC Machining of Titanium: Maximizing Precision and Efficiency in Aerospace Applications

Introduction to 5-Axis CNC Machining in Aerospace Applications The 5-axis Computer Numerical Control (CNC) machining is a technological innovation critical to the aerospace industry that brings about improved precision and enhanced efficiency. Unlike its predecessors such as the 3-axis and 4-axis machines, this technology provides five degrees of freedom for tool movement, thus enabling more […]

Brass CNC Machining: The Advantages of Using Brass in Custom Metal Fabrication and Prototyping

Introduction to Brass CNC Machining and Its Importance in Custom Metal Fabrication and Prototyping CNC machining, a digitally-powered manufacturing process that deploys pre-programmed computer software to manipulate tools’ movement and product contours. When brass is the chosen material under this mechanism, we refer to it as Brass CNC Machining. This technique’s overall accuracy, speed, and […]