What are the common challenges in the process of precision CNC machining bronze parts?

What Materials Considerations Are Crucial for CNC Machining Bronze? Bronze alloys vary widely in their composition and properties, impacting their machinability and the quality of the final product. Key considerations include: By understanding these material considerations, manufacturers can optimize their machining processes to improve efficiency and reduce costs while maintaining high-quality outputs. bronze machining How […]

Custom CNC Machining Services for Titanium Parts: Enhancing Aerospace and Medical Industries?

Custom CNC Machining in the Aerospace and Medical Sectors In response to the steady growth of both the aerospace and medical industries, increasingly sophisticated manufacturing techniques have become a necessity. Custom Computer Numerical Control (CNC) machining services for titanium parts is one such technique, providing precise, efficient, and reliable solutions that can deal with the […]

Can Precision CNC Machining Compensate for Material Weaknesses in High-Stress Applications?

The Role of CNC Machining in Material Enhancement In engineering applications where materials are subjected to high stress, the choice and treatment of materials are crucial for the integrity and longevity of the final product. Precision CNC machining emerges as a transformative technology that not only shapes materials but also enhances their properties. This process […]

Why is Brass Preferred for Precision CNC Machining in Food Automation Equipment?

Why Choose Brass for CNC Machining in Food Automation? Brass, with its remarkable machinability and corrosion resistance, stands out as an ideal material for food automation equipment. Used widely in gears, valves, and fittings within food processing machinery, brass not only offers durability but also safety, due to its antimicrobial properties. This introduction sets the […]

Custom Precision Machining of Stainless Steel for Medical Device Applications: What to Consider?

Custom Precision Machining of Stainless Steel for Medical Devices: A Crucial Component in Healthcare In the medical industry, custom precision machining plays a vital role in creating highly specific and advanced tools crucial for healthcare services. One material extensively utilized in this process is stainless steel due to its many favorable properties. Stainless steel is […]

5 Axis CNC Machining of Titanium: Revolutionizing Aerospace Component Manufacturing?

5 Axis CNC Machining: Catalyzing Innovation in Aerospace Component Manufacturing In the realm of aerospace component manufacturing, 5 Axis CNC machining is a groundbreaking technology. Fundamentally, it refers to computer numerical controlled (CNC) machines that maneuver cutting tools across five different axes simultaneously, thus enabling creation of very intricate and precise parts. This complex process […]

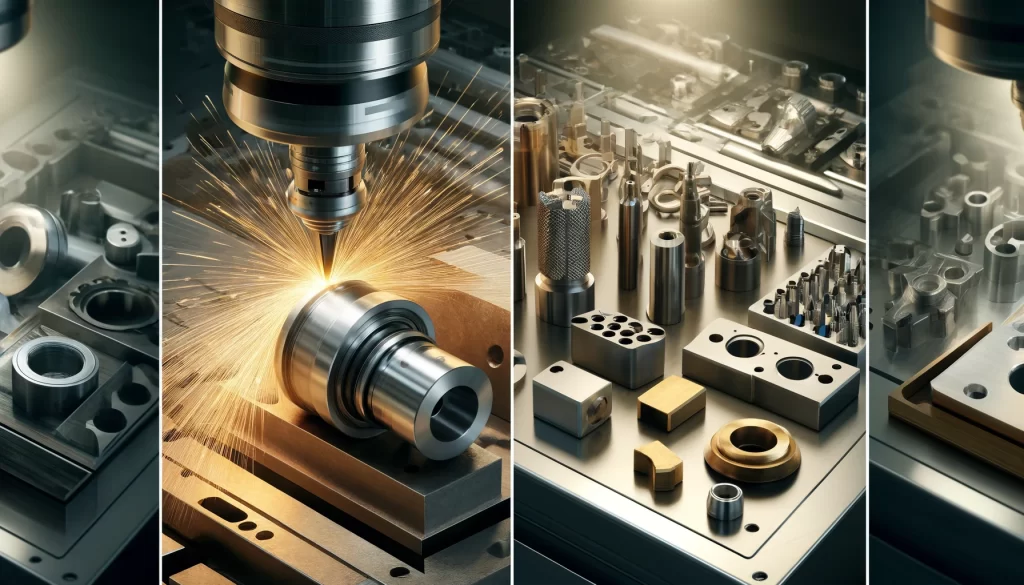

Graphite vs. Bronze in CNC Machining: Which Offers Better Precision and Durability?

Introduction: A Brief Explanation of CNC Machining and the Purpose of this Article CNC machining, standing for Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software commands the movement of factory machinery and tools. This process enables intricate engineering with utmost precision by fully automating equipment functions in three dimensions. However, choosing […]

Ceramics vs. Hardened Steels: Who Wins for Wear Resistance in CNC Parts Manufacturing?

Ceramics vs. Hardened Steels in CNC Parts Manufacturing: A Brief Overview In the field of Computer Numerical Control (CNC) parts manufacturing, two materials often come to the forefront for their wear-resistance properties: ceramics and hardened steels. Ceramics are non-metallic, inorganic solids that offer high heat resistance, remarkable hardness, and low frictional behavior while disadvantaged by […]

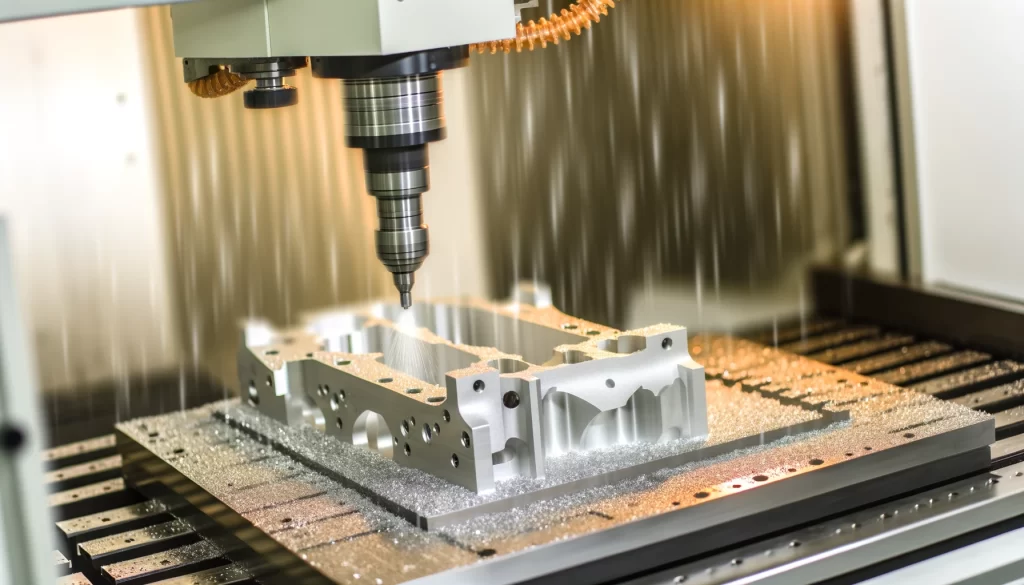

What CNC Machining Techniques Are Best for Aluminum Parts in Food Automation?

Introduction to CNC Machining of Aluminum for Food Automation In the realm of food automation, precision and reliability are paramount. Aluminum parts play a critical role due to their resilience and lightweight nature, which are essential in high-speed food processing environments. CNC machining offers unparalleled precision, making it indispensable for producing complex aluminum parts that […]

How Does Precision CNC Machining Overcome Challenges with Aluminum?

Introduction to Aluminum in Precision CNC Machining Aluminum is renowned for its lightweight yet strong properties, making it a preferred material in industries ranging from aerospace to electronics. Its adaptability and excellent thermal and electrical conductivity also contribute to its widespread use. However, aluminum presents unique challenges when subjected to precision CNC machining processes. These […]

Nylon CNC Machining Service for Custom Parts

Nylon is an engineering plastic known for its high strength, wear resistance, and chemical inertness. It possesses excellent mechanical properties and durability, making it widely used in various fields including mechanical parts, automotive components, electronics, and sports equipment.Nylon CNC machining finds extensive applications in automotive parts (e.g., brake system components, transmission parts), mechanical parts (e.g., […]

How to Optimize CNC Machine Settings for High-Quality Dental Implants Production?

Introduction: The Importance of Precision in CNC Machining for Dental Implants In the world of medical device manufacturing, precision is not merely a goal; it’s a requirement. CNC (Computer Numerical Control) machining stands out as a pivotal technology in the production of dental implants, where each specification must be meticulously met to ensure the implants […]