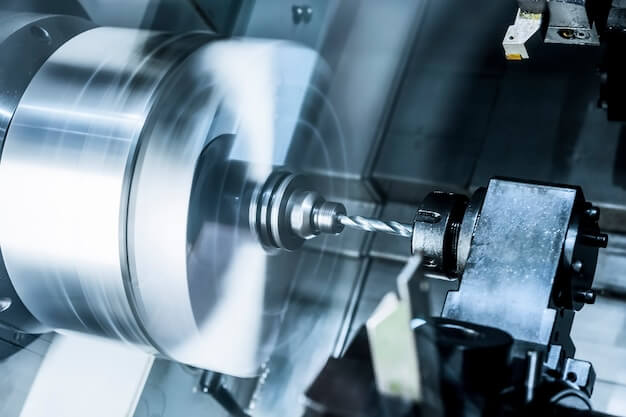

Tool Steel vs. Carbide: A CNC Machining Showdown for Maximum Durability

Introduction to Tool Steel and Carbide in CNC Machining In CNC machining, the selection of the right material is crucial for ensuring durability. Two common materials used are tool steel and carbide. Tool steel is a type of high-carbon alloy steel that offers exceptional toughness and heat resistance making it ideal for low production runs […]

Inconel vs. Monel: Precision CNC Machining for High-Performance Alloys

Inconel vs. Monel: Understanding High-Performance Alloys Comprehension of high-performance alloys, such as Inconel and Monel, is essential in determining their application in precision CNC machining. Inconel belongs to the family of austenitic superalloys generally known for exceptional resistance to corrosion and extreme temperatures, making them suitable for rigorous operating conditions like in aircraft engines or […]

Can Precision CNC Machining Meet the Customization Needs of Medical Joint Replacements?

Introduction: The Role of Precision CNC Machining in Medical Device Manufacturing? Precision CNC machining is indispensable in the field of medical device manufacturing, enabling the production of devices with the utmost accuracy and consistency. This technology is particularly critical in the fabrication of medical joint replacements, where each component must match precise specifications for successful […]

What is the Optimal Cutting Depth for CNC Machining Parts Used in Bone Screws?

Introduction: Understanding Cutting Depth in CNC Machining CNC machining stands as a cornerstone in the manufacturing of complex, precision-based medical devices such as bone screws. The setting of the cutting depth—a critical parameter—determines the amount of material removed with each pass of the cutting tool, impacting everything from the screw’s structural integrity to its surface […]

Tool Steel Grades in CNC Machining: A Comparison of D2 vs. A2 for Durability and Precision

Understanding Tool Steel Grades: The Importance of Selection for CNC Machining In the realm of Computer Numerical Control (CNC) machining, tool steel grades play a crucial role in determining the durability, precision and overall performance of the fabricated parts. Defining tool steel grades fundamentally refers to different alloys of iron-based materials that are heat-treated to […]

Using Super Duplex Stainless Steel in CNC Machining: Advantages for High-Corrosion Resistance Parts

Introduction to Super Duplex Stainless Steel and CNC Machining Super duplex stainless steel, a prominent material in the manufacturing industry, possesses an optimized balance of properties that make it desirable for numerous demanding applications. Characterised by its dual phase structure – containing roughly equal parts of ferrite and austenite – super duplex stainless steels exhibit […]

CNC Machining of Rare Metals: Beryllium Copper vs. Tantalum for Specialized Applications

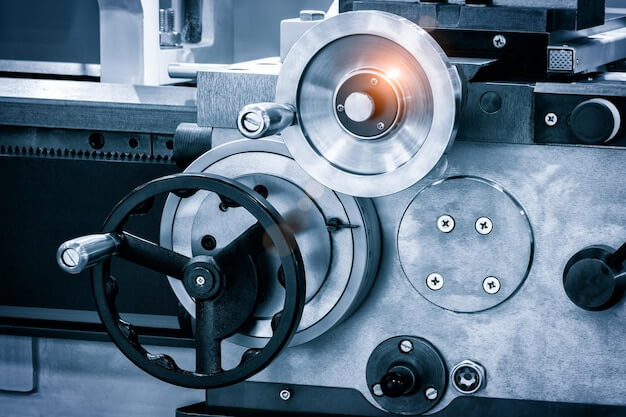

Understanding CNC Machining In manufacturing, Computer Numerical Control (CNC) machining is a crucial method that enables high precision and efficiency through automated control of machine tools. Its significance rests on its ability to produce complicated parts with limited human intervention, thereby increasing productivity while reducing errors and production time. When it comes to specialized applications […]

How Does Feed Rate Influence the Durability of CNC Machining Parts Used in Dental Implants?

Introduction: The Crucial Role of Feed Rate in CNC Machining of Dental Implants In the sophisticated realm of medical device manufacturing, CNC machining stands out for its precision and repeatability, making it indispensable in the production of dental implants. The choice of parameters, especially the feed rate, plays a pivotal role in determining the quality […]

How Does Cutting Speed Influence the Quality of CNC Machining Parts for Spinal Implants?

Introduction: The Importance of Cutting Speed in CNC Machining of Spinal Implants In the intricate world of medical device manufacturing, CNC (Computer Numerical Control) machining represents a cornerstone technology, celebrated for its ability to produce complex, high-precision components. Among these, spinal implants stand out due to their critical role in patient recovery and their stringent […]

How to Select the Most Suitable Machining Parameters for Complex Shape Parts in CNC?

Introduction to CNC Machining of Complex Shapes CNC machining has revolutionized the manufacturing industry by enabling the production of complex shapes with high precision and efficiency. This technology utilizes computerized controls and machine tools to remove layers of material from a stock piece, known as the workpiece, to produce a custom-designed part or product. This […]

Hardened Tool Steels for CNC: Is D2 or A2 Better for Your Precision Manufacturing Needs?

Introduction: The Importance and Basics of Choosing Right Tool Steels in CNC Manufacturing In precision manufacturing, especially in Computer Numerical Control (CNC) processes, the selection of the most appropriate tool steel greatly impacts production efficiency, product quality, and overall cost-effectiveness. The importance of this choice is rooted in the inherent properties of the steel used […]

Ceramic Composite Materials in CNC Machining: Are They the Future of Aerospace Components?

Introduction to CNC Machining and Ceramic Composite Materials CNC (Computer Numerical Control) machining is a pivotal manufacturing process in the aerospace industry. It’s characterized by automated control of machine tools through software inputs, ensuring precision-engineering of components that are critical for constructing aircrafts and their engines. This meticulous approach enhances accuracy, quality control and contributes […]