Weighing the Costs Titanium vs Aluminum in CNC Machined Parts

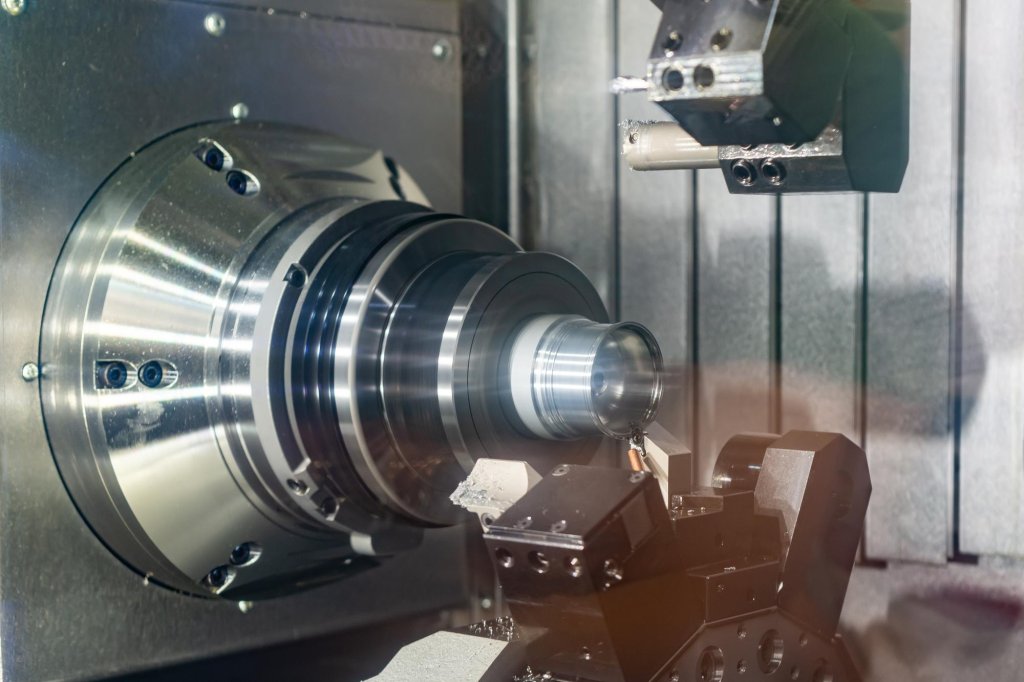

When it comes to CNC machining, choosing the right material is a crucial decision that can significantly impact the cost, performance, and longevity of the final product. Two of the most commonly used materials in CNC machining are titanium and aluminum. Both materials offer unique advantages and are widely used across various industries, from aerospace […]

Mastering Titanium Alloy CNC Machining A Practical Guide

Introduction In the world of CNC machining, titanium alloys have carved a niche for themselves, known for their excellent strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. These properties make titanium alloys highly desirable in industries such as aerospace, medical devices, and automotive. However, the very characteristics that make titanium alloys valuable also […]

Stainless Steel Machining for Aerospace: Precision and Challenges in CNC Operations?

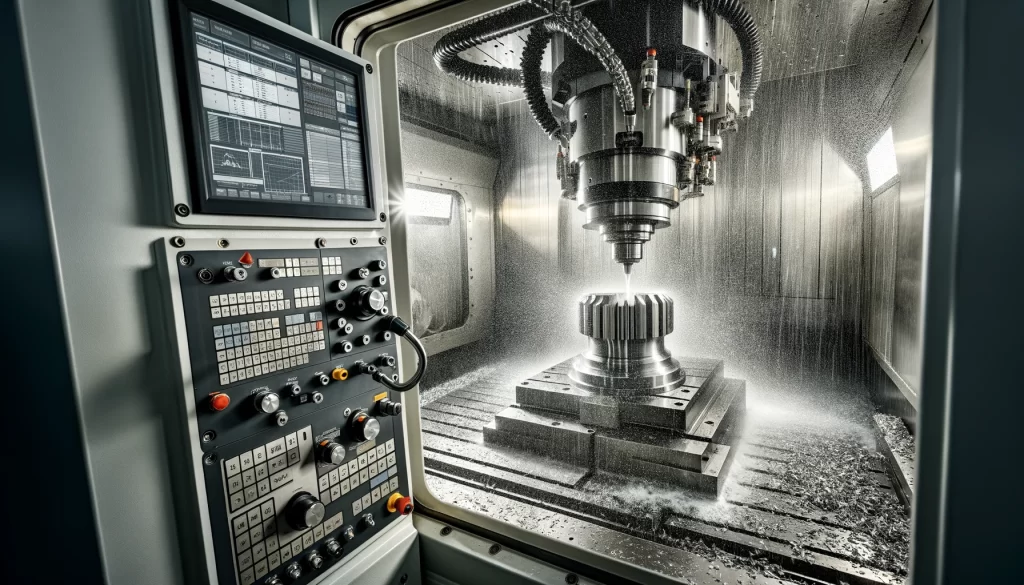

Introduction: Brief Overview of CNC Machining and Its Importance in the Aerospace Industry Computer Numerical Control (CNC) machining is a modern manufacturing process using pre-programmed computer software to control movement of machinery. It plays a significant role in creating complex three-dimensional parts with high precision, speed and reliability – factors which are critically important in […]

5-Axis CNC Machining of Titanium: Exploring Cost and Production Efficiency?

Introduction to 5-Axis CNC Machining and its Role in Manufacturing Industry The revolutionary technique of Five-axis Computer Numeric Control machining, or simply 5-axis CNC machining, plays an integral role within the manufacturing industry. Its superior precision and vast adaptability enable manufacturers to sculpt intricate components out of a multitude of materials efficiently. While it is […]

Precision CNC Machining for Medical Devices: Titanium and Stainless Steel

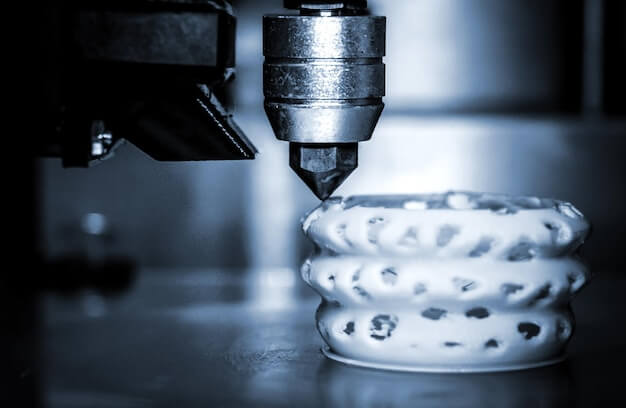

Precision CNC Machining for Medical Devices: Titanium and Stainless Steel The field of CNC machining plays an essential role in the medical device industry. It involves programming computer software to dictate automated machinery movements, enabling high-speed, precision manufacturing with stringent quality control – a vital feature when producing lifesaving medical equipment or devices. This technology […]

What Should You Look for in a Precision CNC Machining Partner for Carbon Steel Automotive Ball Joints?

What Are the Technical Challenges in Machining Carbon Steel for Automotive Ball Joints? Machining carbon steel for automotive ball joints involves several technical challenges that must be addressed to achieve high-quality, reliable parts. Understanding these challenges is crucial in selecting the right CNC machining partner. 1. Material Hardness and Tool WearCarbon steel’s hardness contributes to […]

What Are the Key Challenges in CNC Machining Carbon Steel for Automotive Parts and How Can They Be Overcome?

What Makes Carbon Steel a Challenging Material for CNC Machining? Carbon steel is widely used in the automotive industry due to its strength, durability, and cost-effectiveness. However, it presents several challenges in CNC machining that require careful consideration and specialized techniques to overcome. 1. Hardness and ToughnessCarbon steel’s hardness and toughness are beneficial for the […]

What Factors Should You Consider When Selecting a Precision CNC Machining Partner for Carbon Steel?

What Are the Key Technical Challenges in Precision CNC Machining of Carbon Steel? Precision CNC machining of carbon steel involves several technical challenges that need to be addressed to achieve optimal results. Understanding these challenges is crucial in selecting a capable machining partner. 1. Material Hardness and Tool WearCarbon steel’s high hardness can cause significant […]

How Is CNC Machining Used in the Production of SpaceX’s Starship Components?

Precision Requirements for SpaceX Starship Components CNC machining is crucial for producing SpaceX’s Starship components due to the high precision requirements needed for space applications. The Starship’s complex geometry and the need for parts to fit perfectly together necessitate the use of CNC machining, which can achieve tolerances as tight as ±0.005 mm. Achieving such […]

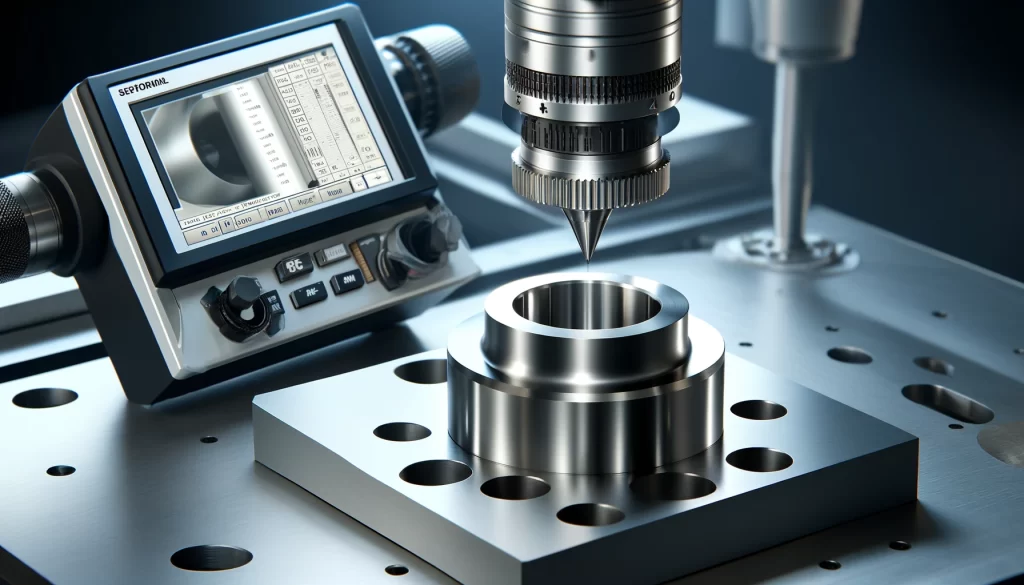

How Does CNC Machining Achieve Precision Tolerances in Stainless Steel Parts?

The Importance of Precision Tolerances in Stainless Steel Parts Precision tolerances are the allowable limits of variation in a physical dimension. In CNC machining, particularly for stainless steel parts, achieving these tolerances is critical for several reasons: The importance of precision is underscored by its impact on the end product. For instance, in the aerospace […]

Precision Machining of Brass: Custom Solutions for Medical Applications

Precision Machining of Brass: A Key Method for Medical Applications Precision machining is a specialized process used to create highly accurate and intricate parts and components. It utilizes advanced software-controlled machinery equipped with high-precision tools to remove material from a workpiece in order to achieve the desired shape and design. With regard to brass manufacturing, […]

How Can Surface Finish Be Optimized in CNC Machining of Stainless Steel?

What Factors Affect Surface Finish in CNC Machining of Stainless Steel? The quality of the surface finish in CNC machining stainless steel is influenced by a variety of factors ranging from machine settings to the physical properties of the material: Detailed Factors Table: Factor Impact on Surface Finish Recommended Practices Material Hardness Increases tool wear […]