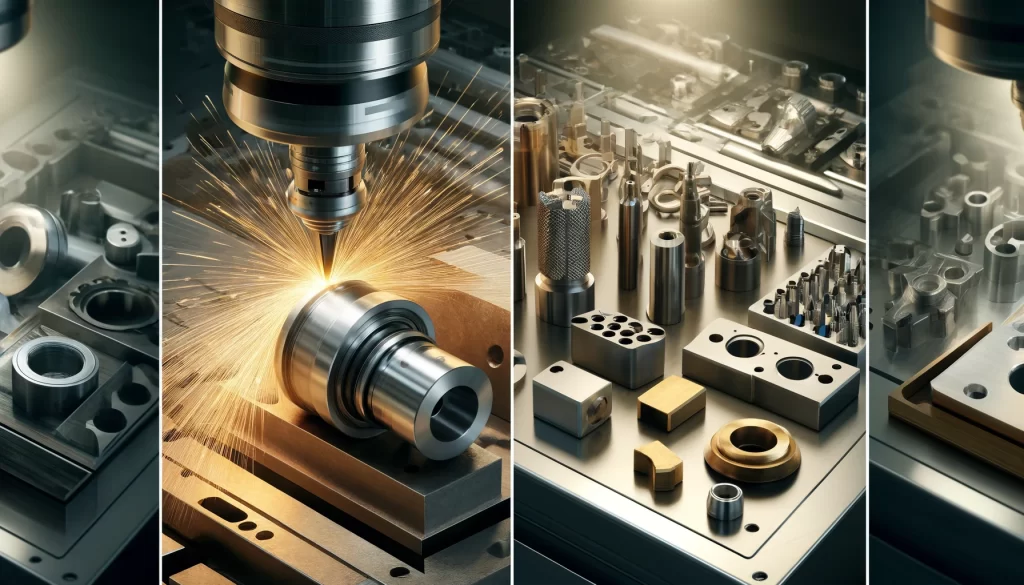

What Criteria Define the Best CNC Machining Service for Precision Copper Manufacturing?

Understanding Precision CNC Machining for Copper The precision CNC machining process requires a deep understanding of the properties of copper. Copper is known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance, but it is also a soft metal that poses unique challenges for CNC machining. Effective machining of copper requires specialized tooling and […]

Titanium Parts CNC Machining: Advancements and Applications in Medical Device Manufacturing

Titanium Parts CNC Machining in Medical Device Manufacturing As a cornerstone of medical manufacturing, the combination of Titanium parts and Computer Numerical Control (CNC) machining bring immense value to this critical industry. For those unfamiliar with these terms, titanium is an incredibly strong but lightweight metal that is highly resistant to corrosion, making it ideal […]

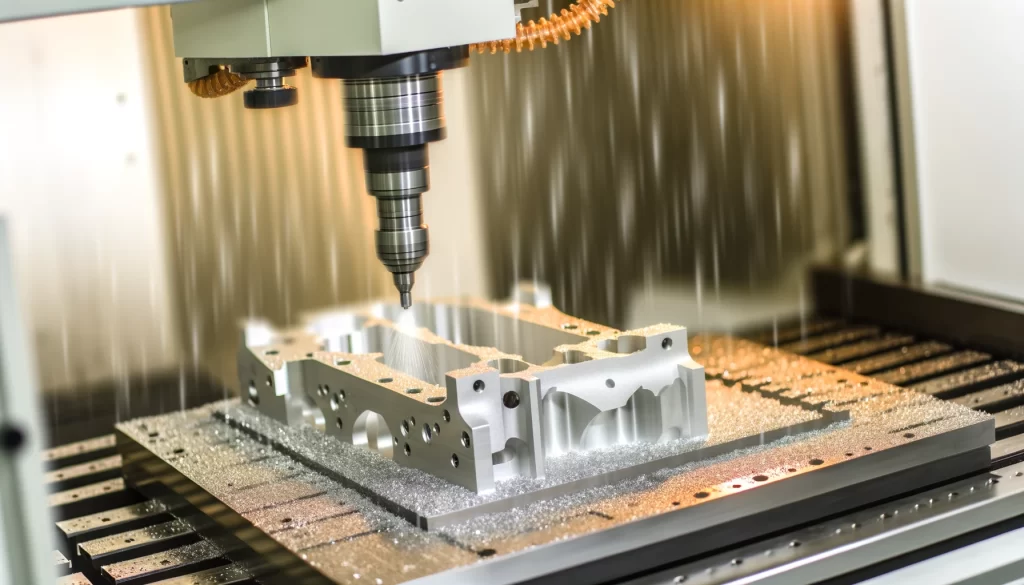

5-Axis CNC Machining of Titanium: Maximizing Precision and Efficiency in Aerospace Applications

Introduction to 5-Axis CNC Machining in Aerospace Applications The 5-axis Computer Numerical Control (CNC) machining is a technological innovation critical to the aerospace industry that brings about improved precision and enhanced efficiency. Unlike its predecessors such as the 3-axis and 4-axis machines, this technology provides five degrees of freedom for tool movement, thus enabling more […]

What are the common challenges in the process of precision CNC machining bronze parts?

What Materials Considerations Are Crucial for CNC Machining Bronze? Bronze alloys vary widely in their composition and properties, impacting their machinability and the quality of the final product. Key considerations include: By understanding these material considerations, manufacturers can optimize their machining processes to improve efficiency and reduce costs while maintaining high-quality outputs. bronze machining How […]

Custom CNC Machining Services for Titanium Parts: Enhancing Aerospace and Medical Industries?

Custom CNC Machining in the Aerospace and Medical Sectors In response to the steady growth of both the aerospace and medical industries, increasingly sophisticated manufacturing techniques have become a necessity. Custom Computer Numerical Control (CNC) machining services for titanium parts is one such technique, providing precise, efficient, and reliable solutions that can deal with the […]

Can Precision CNC Machining Compensate for Material Weaknesses in High-Stress Applications?

The Role of CNC Machining in Material Enhancement In engineering applications where materials are subjected to high stress, the choice and treatment of materials are crucial for the integrity and longevity of the final product. Precision CNC machining emerges as a transformative technology that not only shapes materials but also enhances their properties. This process […]

5 Axis CNC Machining of Titanium: Revolutionizing Aerospace Component Manufacturing?

5 Axis CNC Machining: Catalyzing Innovation in Aerospace Component Manufacturing In the realm of aerospace component manufacturing, 5 Axis CNC machining is a groundbreaking technology. Fundamentally, it refers to computer numerical controlled (CNC) machines that maneuver cutting tools across five different axes simultaneously, thus enabling creation of very intricate and precise parts. This complex process […]

Titanium vs. Inconel: Which is the Superior Material for High-Stress CNC Applications?

Introduction: CNC Applications and the Importance of Material Strength In high-stress tasks, such as those performed by Computer Numerical Control (CNC) machines, the strength of the material used plays a crucial role. Primarily utilized in industries including automotive, aerospace, and electronics, CNC applications carry out repetitive operations with immaculate precision, often under exceedingly high pressures […]

How Does Precision CNC Machining Overcome Challenges with Aluminum?

Introduction to Aluminum in Precision CNC Machining Aluminum is renowned for its lightweight yet strong properties, making it a preferred material in industries ranging from aerospace to electronics. Its adaptability and excellent thermal and electrical conductivity also contribute to its widespread use. However, aluminum presents unique challenges when subjected to precision CNC machining processes. These […]

How to Optimize CNC Machine Settings for High-Quality Dental Implants Production?

Introduction: The Importance of Precision in CNC Machining for Dental Implants In the world of medical device manufacturing, precision is not merely a goal; it’s a requirement. CNC (Computer Numerical Control) machining stands out as a pivotal technology in the production of dental implants, where each specification must be meticulously met to ensure the implants […]

Zirconium vs. Titanium: Evaluating CNC Machining for Critical Applications

Introduction: Zirconium vs. Titanium in CNC Machining In recent years, we’ve observed an increasing trend in the use of zirconium and titanium materials in the artful domain of CNC machining. These two robust metals have emerged as important resources due to their unique combination of high strength, light weight, and exceptional corrosion resistance. Nonetheless, there […]

Can Precision CNC Machining Meet the Customization Needs of Medical Joint Replacements?

Introduction: The Role of Precision CNC Machining in Medical Device Manufacturing? Precision CNC machining is indispensable in the field of medical device manufacturing, enabling the production of devices with the utmost accuracy and consistency. This technology is particularly critical in the fabrication of medical joint replacements, where each component must match precise specifications for successful […]