1. Introduction: Setting the Stage for Quality Excellence

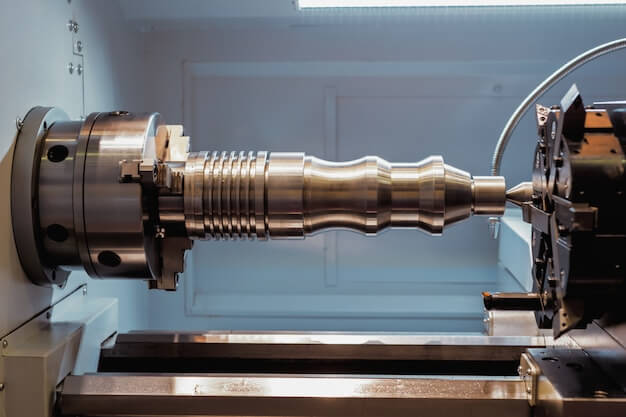

In this introductory section, we lay the groundwork for an exploration into the world of quality assurance in China CNC machining. We discuss the pivotal role that dependable quality plays in the manufacturing landscape and introduce the key components of quality assurance in CNC machining.

2. Key Components of Quality Assurance in China CNC Machining

This section provides a detailed breakdown of the essential components that contribute to the dependable quality assurance in China CNC machining. Utilizing a comprehensive list, we delve into factors that ensure precision, consistency, and reliability:

- Rigorous Inspection Protocols: Implementing thorough checks at various stages of the machining process.

- Advanced Metrology Equipment: Utilizing state-of-the-art measurement tools for accurate quality assessments.

- Skilled Workforce Training: Ensuring operators are well-trained to uphold quality standards.

- Material Quality Control: Implementing stringent controls on raw materials to meet specified standards.

3. Real-world Applications: Quality Assurance in Action

Highlighting practical applications, this section explores real-world scenarios where dependable quality assurance practices in China CNC machining have made a significant impact. Through case studies and examples, readers gain insights into how industries benefit from robust quality assurance protocols.

4. Comparative Analysis: Quality Assurance Benchmarks in China CNC Machining

In this pivotal section, we provide a comparative analysis of quality assurance benchmarks in China CNC machining. Utilizing a structured table format, we highlight key aspects:

| Quality Parameter | China CNC Machining | Industry Norms |

|---|---|---|

| Tolerance Levels | Extremely tight tolerances | Standard tolerances |

| Surface Finish | Consistently high-quality finish | Varied surface finishes |

| Inspection Protocols | Rigorous inspection procedures | Standard inspection methods |

| Material Compatibility | Expertise in machining diverse materials | Limited material expertise |

5. Strategic Quality Management: Navigating Future Trends

Concluding the article, we explore strategic considerations for the future of quality assurance in China CNC machining. By discussing emerging trends, technological advancements, and the evolving role of quality management, we provide a forward-looking perspective on maintaining and enhancing dependable quality in the dynamic world of CNC machining.

By the end of this comprehensive exploration, readers will have gained a profound understanding of the dependable quality assurance practices in China CNC machining, the key components ensuring quality excellence, real-world applications, a comparative analysis with industry norms, and strategic insights for navigating future trends in quality management.

Other Articles You Might Enjoy

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…