As industries strive to become more environmentally conscious, the materials used in CNC machining are evolving. One of the most significant changes in this domain is the shift from traditional leaded brass to lead-free brass alloys. This transition is crucial for both environmental sustainability and public health. Let’s explore how these changes are shaping the future of CNC machining parts.

The Rise of Leaded Brass

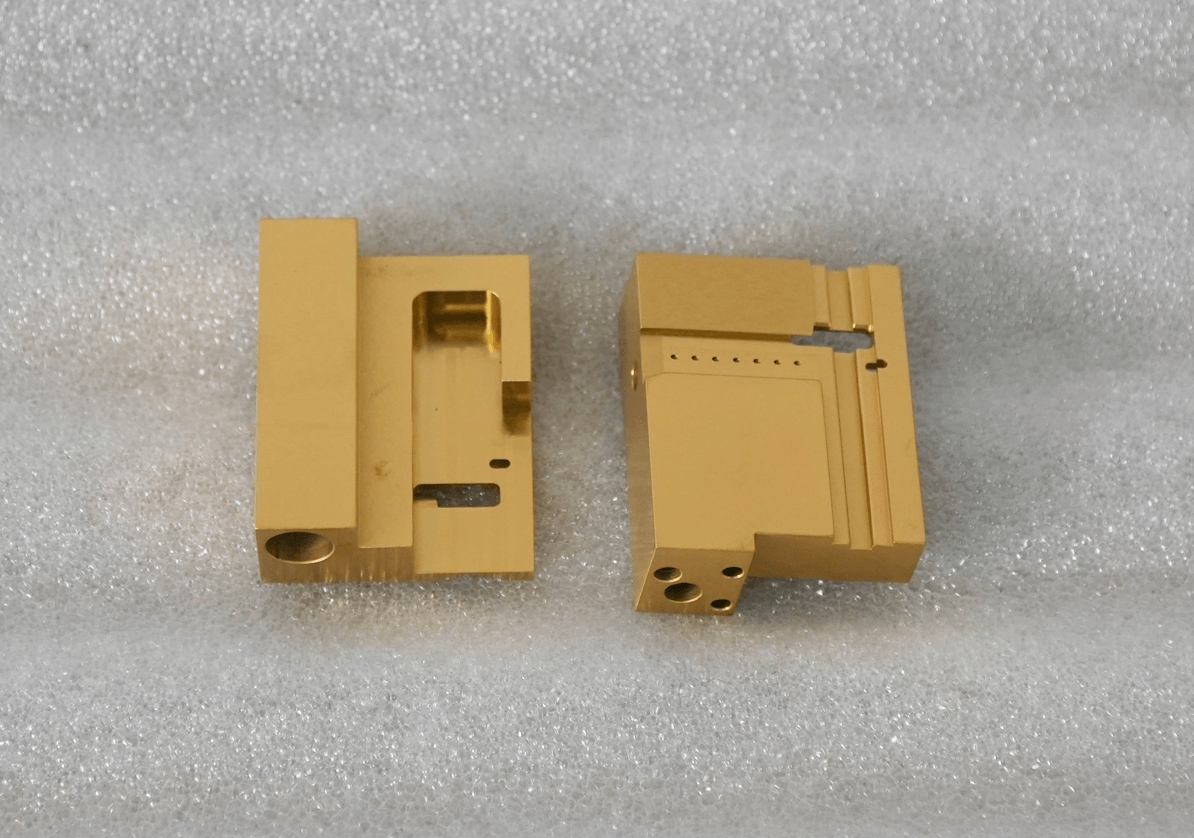

Leaded brass has been a staple in the machining industry due to its excellent machinability. Common leaded brass alloys like HPb59-1, ZCuZn40Pb2, and HPb63-3 contain lead, which is dispersed in a free state within the brass matrix. This distribution of lead, which appears as tiny, uniform particles, enhances the machinability of the alloy by providing soft spots that facilitate smooth cutting. This results in a high-quality surface finish, making leaded brass suitable for intricate components used in various sectors such as electronics, plumbing, and automotive industries.

Leaded brass is not only easy to machine but also adaptable to various casting methods, including die casting and continuous casting. This versatility has made it a popular choice, especially in countries where brass is extensively used for plumbing applications. In fact, in many developed nations, over 90% of water pipes are made from brass. The automotive industry, too, favors leaded brass due to its lower overall machining costs compared to leaded steel.

The Environmental and Health Concerns

Despite its advantages, leaded brass poses significant environmental and health risks. When leaded brass products are discarded, lead can easily leach into the soil and water, posing a severe threat to the ecosystem and human health. Additionally, when these products are incinerated, lead can enter the atmosphere, leading to air pollution. The dangers are particularly acute when leaded brass is used in drinking water systems, as lead can leach into the water supply, causing severe health issues.

Recognizing these risks, many developed countries have enacted strict regulations to phase out the use of leaded brass in potable water systems, toys, and household appliances. This regulatory push is driving the demand for environmentally friendly alternatives.

The Emergence of Lead-Free Brass

In response to these challenges, the industry is shifting towards lead-free brass alloys, with bismuth brass emerging as a leading alternative. Bismuth, like lead, is dispersed throughout the brass matrix, improving machinability without the associated health risks. The United States has been at the forefront of this transition, developing eight grades of bismuth brass, including C89510, C89520, C89550, C89325, C89831, C89833, C89835, and C89837. These alloys often incorporate other elements like tin and nickel to enhance their properties.

While bismuth brass is more expensive to produce than leaded brass, its environmental benefits and compliance with health regulations justify the cost. However, the transition is not without its challenges. Bismuth brass has different welding characteristics compared to leaded brass, which can complicate manufacturing processes. Despite these hurdles, the push for safer, greener materials is strong.

Practical Considerations in CNC Machining

For machinists, the shift to lead-free brass means adapting to new materials with different properties. Here are some practical considerations:

- Machinability: While bismuth brass offers good machinability, it behaves differently than leaded brass. Machinists may need to adjust their cutting parameters, such as feed rate and cutting speed, to optimize performance.

- Tool Wear: Lead-free brass alloys can cause different wear patterns on cutting tools. Monitoring and adjusting tooling strategies is essential to maintain efficiency and quality.

- Welding and Joining: As mentioned, bismuth brass may present challenges in welding. Understanding these differences and adapting techniques is crucial for producing reliable parts.

- Cost Management: Although lead-free brass is more expensive, efficient machining practices can help mitigate costs. Leveraging the alloy’s benefits while optimizing machining processes will be key.

Data Table: Comparing Leaded and Lead-Free Brass

| Property | Leaded Brass (HPb59-1) | Lead-Free Brass (C89520) |

|---|---|---|

| Lead Content (%) | 2.5 – 3.5 | 0 |

| Bismuth Content (%) | 0 | 0.5 – 1.5 |

| Machinability | Excellent | Very Good |

| Environmental Impact | High | Low |

| Health Risk | High | None |

| Cost | Lower | Higher |

Future Prospects

The future of CNC machining parts is undoubtedly moving towards more sustainable materials. As regulations tighten and industries commit to greener practices, the adoption of lead-free brass will continue to grow. This transition not only helps protect the environment and public health but also pushes the industry towards innovative solutions and improved machining practices.

Other Articles You Might Enjoy

- CNC Machining Aluminum vs. Brass: A Detailed Comparison for Precision Parts Manufacturing

Introduction to CNC Machining and Material Choices CNC (Computer Numerical Control) machining is a critical process in precision parts manufacturing. Its importance lies in its ability to create intricate and…

- What Are the Latest Trends in Sourcing Brass CNC Machining Parts?

How Are Global Market Dynamics Shaping the Sourcing of Brass CNC Machining Parts? The global landscape for sourcing brass CNC machining parts is heavily influenced by international trade dynamics, including…

- CNC Machining Aluminum vs. Brass: A Detailed Comparison for Precision Parts Manufacturing

CNC Machining: Aluminum vs. Brass in Precision Parts Manufacturing The continuous quest for efficiency and precision has made CNC (Computer Numerical Control) machining a vital process in the manufacturing of…

- Requirements for CNC Machining Parts

Preparation Work Complete the necessary preparation before machining, including process analysis, process route design, tool and fixture selection, and program compilation. online cnc machining service Operating Steps and Contents Start…

- What Strategies Can Optimize Inventory Management of Brass CNC Machining Parts?

What is Inventory Management in the Context of Brass CNC Machining Parts? Inventory management in the brass CNC machining sector involves overseeing the flow of components from suppliers to the…

- How Do Import Regulations Affect the Procurement of Brass CNC Machining Parts?

What Are the Global Import Regulations for Brass CNC Machining Parts? The global landscape for importing brass CNC machining parts is complex and varies significantly by country. Key players such…