In the realm of industrial manufacturing, the integration of CNC machining and chrome plating on cast iron components stands as a pivotal advancement, driving quality, precision, and durability to new heights. This article delves into the intricate relationship between CNC machining and chrome plating, exploring how this synergy benefits manufacturers, suppliers, and end-users alike.

Introduction

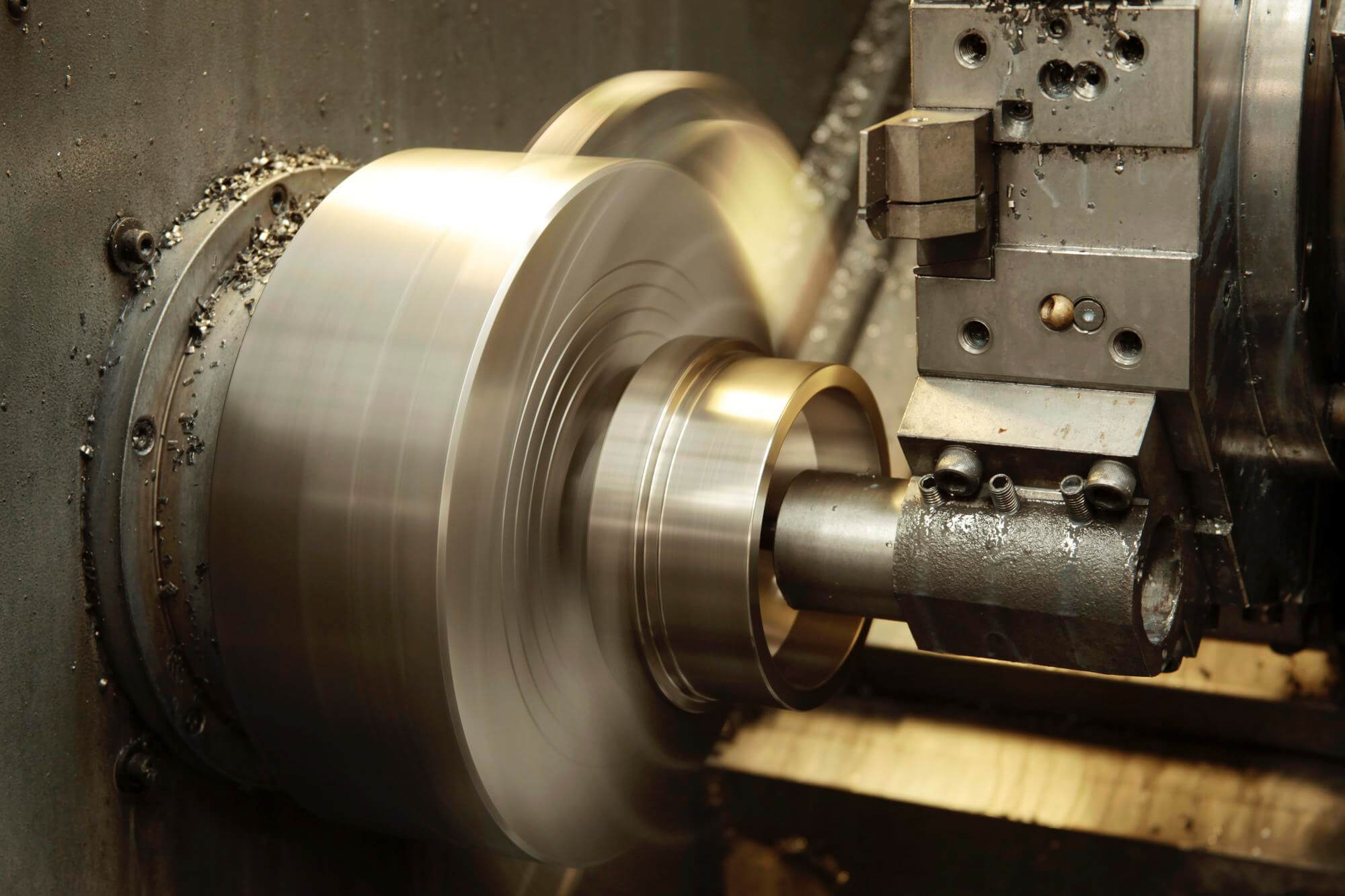

CNC machining has revolutionized the way we process materials, offering unparalleled precision and repeatability. When it comes to working with cast iron, a material renowned for its strength and wear resistance, CNC machining becomes even more critical. Cast iron, though robust, poses unique challenges in machining due to its brittleness and tendency to create abrasive chips. The application of chrome plating to cast iron components further enhances their wear resistance, corrosion protection, and overall longevity. However, the success of chrome plating heavily depends on the quality of the machined surface, making CNC machining an indispensable step in the process.

The Role of CNC Machining in Preparing Cast Iron for Chrome Plating

1. Surface Preparation

One of the primary functions of CNC machining in the context of chrome plating is surface preparation. The process involves removing surface irregularities, ensuring a smooth, even surface that is ideal for chrome adhesion. CNC machining allows for tight control over the surface finish, which is crucial for achieving uniform chrome plating. A rough or uneven surface can lead to poor adhesion, resulting in peeling or flaking of the chrome layer.

2. Dimensional Accuracy

CNC machining is known for its ability to maintain high dimensional accuracy, a feature that is particularly important when preparing cast iron components for chrome plating. The layer of chrome plating adds to the overall dimensions of the part. Therefore, precise machining is necessary to ensure that after plating, the component meets the required specifications. CNC machining allows for the fine-tuning of dimensions to account for the additional thickness introduced by chrome plating.

3. Edge and Corner Refinement

Another critical aspect of CNC machining in preparation for chrome plating is the refinement of edges and corners. Sharp edges can lead to uneven chrome distribution, while poorly machined corners can cause plating defects. CNC machining allows for the precise rounding or chamfering of edges, creating a more uniform surface that is better suited for the plating process.

Challenges in CNC Machining of Cast Iron

1. Abrasive Chips and Tool Wear

Cast iron machining is notorious for producing abrasive chips that can accelerate tool wear. This challenge is compounded when machining is conducted in preparation for chrome plating, where surface finish and precision are paramount. To counteract this, specialized cutting tools and coatings are often employed, along with optimized machining parameters to minimize tool wear and maintain surface integrity.

2. Brittleness and Chipping

Cast iron’s brittleness makes it susceptible to chipping, especially during high-speed CNC operations. This can compromise the quality of the machined surface, making it unsuitable for chrome plating. Understanding the material’s behavior under different cutting conditions is crucial. Adjustments to feed rates, cutting speeds, and the use of appropriate cutting fluids can help mitigate these issues.

3. Residual Stresses

The machining of cast iron can induce residual stresses within the material, which may manifest during or after the chrome plating process, leading to warping or distortion of the component. Managing these stresses through proper machining strategies and post-machining treatments, such as stress-relief annealing, is essential to ensure the stability of the plated part.

Chrome Plating: Enhancing the Properties of CNC-Machined Cast Iron

Chrome plating serves as a protective layer that significantly enhances the properties of cast iron components. The synergy between CNC machining and chrome plating results in parts that are not only dimensionally accurate but also highly resistant to wear, corrosion, and extreme temperatures.

1. Wear Resistance

One of the primary benefits of chrome plating on CNC-machined cast iron is the substantial increase in wear resistance. This is particularly beneficial in applications where the component is subjected to constant friction or contact with abrasive materials. The hard chrome layer acts as a barrier, protecting the underlying cast iron from wear and extending the component’s lifespan.

2. Corrosion Protection

Cast iron is prone to rusting, especially in environments with high humidity or exposure to chemicals. Chrome plating provides an excellent solution by forming a protective layer that shields the cast iron from corrosive elements. The quality of this protection is directly related to the smoothness and uniformity of the underlying machined surface, which CNC machining ensures.

3. Aesthetic and Functional Benefits

Beyond protection, chrome plating also offers aesthetic and functional benefits. A well-machined and plated cast iron component has a shiny, reflective surface that is both visually appealing and easy to clean. In applications where appearance and hygiene are important, such as in automotive or food processing equipment, this combination of CNC machining and chrome plating is particularly advantageous.

The CNC Machining Process for Chrome-Plated Cast Iron Components

1. Material Selection and Tooling

The CNC machining process for cast iron begins with material selection and tooling considerations. High-quality cast iron grades suitable for chrome plating must be chosen to ensure compatibility with both the machining and plating processes. Additionally, tools must be selected for their durability and ability to produce the desired surface finish without excessive wear.

2. Machining Strategies

Machining strategies for cast iron intended for chrome plating must focus on achieving the smoothest possible surface while minimizing tool wear. This often involves the use of multiple machining passes, with progressively finer cuts to refine the surface finish. Tool paths and cutting parameters must be carefully planned to avoid inducing stresses or heat that could affect the material’s behavior during plating.

3. Post-Machining Treatments

After machining, post-processing treatments such as stress-relief annealing or polishing may be necessary to prepare the component for chrome plating. These treatments help eliminate residual stresses and improve surface quality, ensuring that the chrome layer adheres properly and performs as expected.

Case Studies and Applications

1. Automotive Components

In the automotive industry, chrome-plated cast iron components are commonly used for their durability and corrosion resistance. CNC machining ensures that these parts meet the precise tolerances required for engine components, transmission parts, and other critical applications.

2. Industrial Machinery

Cast iron components in industrial machinery often require both strength and wear resistance. Chrome plating adds an extra layer of protection, while CNC machining ensures the parts are perfectly aligned and dimensioned for their intended use.

3. Aerospace Industry

The aerospace industry demands high-performance materials and precision manufacturing. CNC machining of cast iron components, followed by chrome plating, is used in various aerospace applications where durability and resistance to environmental factors are crucial.

The synergy between CNC machining and chrome plating of cast iron represents a powerful combination that enhances the performance, durability, and longevity of critical components across multiple industries. By understanding the nuances of both processes and how they complement each other, manufacturers can achieve superior results, ensuring that their products meet the highest standards of quality and reliability.

In conclusion, whether you are a supplier, a manufacturer, or a technician working with cast iron components, the integration of CNC machining and chrome plating is essential for producing parts that not only meet but exceed industry expectations.

Other Articles You Might Enjoy

- Affordable CNC Machining for Custom Titanium Parts

Introduction to CNC Machining and its Relevance in Manufacturing CNC (Computer Numerical Control) machining, a mainstay in modern manufacturing, revolutionizes the process of creating complex parts from various materials. This…

- An Insight into CNC Machining and Bead Blasting(cast iron steel Will)

CNC machining is a highly precise and effective method of creating custom parts and components for various industries. Among the numerous procedures in this modern manufacturing process, bead blasting stands…

- Efficient CNC Machining of Lightweight Metal and Chrome Removal( cnc machining services china Atwood)

Computer Numerical Control (CNC) machining is a modern manufacturing process used in various industries, frequently dealing with lightweight metals or needing to remove chrome from metal surfaces. This article will…

- Precision Metalwork: Lightweight CNC Machining and Chrome Removal( cnc machine tools Norman)

CNC machining, a dominant force in the world of manufacturing, is intricately involved with creating complex parts out of lightweight metal, as well as removing chrome from metal components. This…

- Using CNC Machining to Fabricate Lightweight Metal and Remove Chrome From Metal( cnc machining services china Dana)

CNC (Computer Numerically Controlled) machining is an essential process in the manufacturing domain. With its precision, adaptability, and extensive applications, many industries rely on it for fabricating highly complex parts…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…