Precision CNC Machining and its Relevance to Advanced Medical Imaging Devices

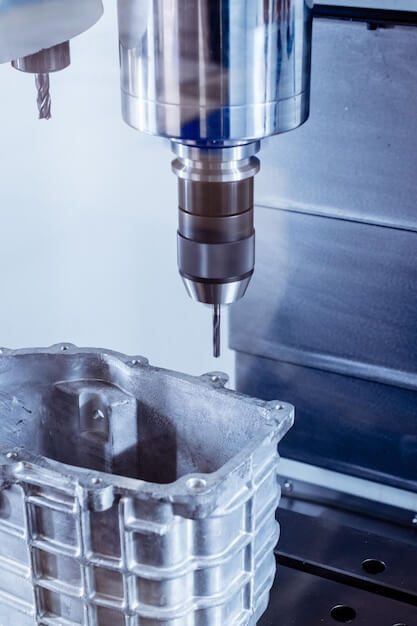

Precision Computer Numerical Control (CNC) machining is a highly accurate manufacturing methodology that entails the use of computers to manage and control machine tools. This sophisticated technology ensures unparalleled precision, repeatability, and accuracy in creating complex shapes that are difficult or impossible to design using manual machines. In the context of advanced medical imaging devices, precision CNC machining takes on an indispensable role.

These intricate systems demand extreme levels of precision and intricacy as they aim to capture clear, detailed images of our body’s internal systems for diagnostic purposes. For instance, components such as CT scanners, MRI machines, Ultrasound transducers, amongst others, heavily rely on precision-machined parts. The scanner frames, gradient coils, RF shields all require high degrees of dimensional accuracy which is achievable only with the aid of Precision CNC machining.

- Scanner Frames: They need to be sturdy yet precisely designed to accommodate various other components.

- Gradient Coils: These are custom-shaped coils requiring high accuracy to generate magnetic fields of specific strengths.

- RF Shields: Minute detailing is necessary to prevent stray radio wavelengths from distorting the image quality.

Hence, precision CNC machining remains essential in facilitating significant advancements in healthcare by ensuring optimum performance of critical, life-saving medical imaging devices.

Understanding Medical Imaging Devices

Advanced medical imaging devices are revolutionary tools that offer a non-invasive mode to explore internal organs and structures of the body. These cutting-edge equipment pieces, like Magnetic Resonance Imaging (MRI) scanners, Computed Tomography (CT) machines, Ultrasound technology, PET scanners, and more, combine use sophisticated computer technologies with principles of physics, radiology, mathematics, and biology to provide high-resolution images that can precisely show even minute tissues or blood vessels. Owing to their precision and advanced capabilities, these imaging devices have turned out to be indispensable in current medicine.

- MRI Scanners: They create detailed images using magnetic field and radio waves; invaluable for diagnosing various conditions including brain injuries, tumors etc.

- CT Machines: Using X-rays from different angles integrated together, they give cross-sectional views of bones, blood vessels and soft tissues, offering more details than regular x-rays.

- Ultrasound Technology: Uses sound waves to produce images, most commonly used during pregnancy but also effective for viewing other soft organ tissues.

- PET Scanners: Mostly used in Oncology for its efficiency in showing metabolic changes occurring at the cellular level before anatomical changes become visible.

In terms of importance, it’s safe to say that without these technologically astute instruments, many diagnoses would remain elusive leading to delayed or inadequate treatment protocols. The technological guidance offered by these devices directly affects prognostic factors, assisting doctors to come up with apt treatment plans based on accurate data provided.

The critical role and importance of precision CNC machining in the production of advanced medical imaging devices:

- Precision CNC machining plays a crucial role in producing components for advanced medical imaging devices, ensuring the high-quality and high-precision manufacturing of parts essential for these critical medical instruments.

- This process enables the creation of intricate and durable components that contribute to the efficiency and reliability of medical imaging devices.

- To explore precision CNC machining for advanced medical imaging devices, consider utilizing Precision Machining Service for efficient and high-quality manufacturing solutions.

Key Benefits of Precision CNC Machining for Advanced Medical Imaging Devices

Precision CNC machining confers an array of benefits to the production process of advanced medical imaging devices. Firstly, it significantly increases efficiency by dramatically reducing both setup and production times, giving manufacturers a solid edge in streamlining operations and meeting challenging deadlines with shorter production cycles.

A second crucial advantage lies in providing greater accuracy. The preciseness introduced by precision CNC machining is unmatched, resulting in products that adhere rigorously to stringent industry standards and custome r specification. High levels of repeatability further guarantee consistent quality across batch productions.

Lastly, another essential benefit is the flexibility in design it offers. Intricate components with complex geometries which were earlier challenging or impossible to fabricate are now easily achievable thanks to the capabilities of precise CNC machining processes. This allows for innovative creations within the field of advanced medical imaging, enabling the development of more sophisticated systems.

Challenges in Advanced Medical Imaging Devices and the Role of Precision CNC Machining

The increasing demand for advanced medical imaging devices coupled with unprecedented accuracy needs presents unique challenges. To begin with, these devices require highly precise parts to ensure reliable performance and accurate diagnostic results. Additionally, they have a high production volume owing to an escalating global need propelled by healthy living consciousness and emphasis on early diagnosis.

Precision CNC machining effectively addresses these issues. For instance, its automated process diminishes errors typically associated with manual handling while enhancing product uniformity across all units, thus meeting the increased demand. More significantly, CNC machines offer unrivaled precision levels which is paramount given that even minute discrepancies can affect an imaging device’s operation negatively thereby compromising the reliability of diagnostic results.

-

In a relevant example, precision CNC machining has facilitated the swift creation of MRI machine components that adhere meticulously to specified dimensions, hence abating concerns regarding measurement inaccuracies.

Future Trends and Developments in Precision CNC Manufacturing for Advanced Medical Imaging Devices

The future of precision CNC manufacturing for advanced medical imaging devices is exciting, with potential innovations poised to revolutionize the industry. Key trends include:

- CNC laser cutting technology – This technique can further enhance the accuracy of complex part production, particularly applicable for intricate parts within high-resolution CT scanners and MRI machines.

- Nanotechnology applications in CNC machining – This could lead to even greater precision levels within microscopic dimensions. This has potential implications for the manufacture of miniaturized imaging equipment suitable for exploratory or non-invasive procedures.

- Adoption of AI (Artificial Intelligence) in CNC systems – A trend sure to streamline processes and improve operational efficiencies. For example, imagine a machine that uses predictive analytics to identify mechanical issues before they become problematic, thereby minimizing downtime and enhancing productivity.

- Integration of IoT (Internet of Things) – The incorporation of connected devices enables real-time monitoring and remote operation, ensuring optimal performance and efficiency. It may aid in achieving a seamless “smart” medical imaging device factory model.

Given these prospective developments, considerable opportunities exist for innovation and enhancement within CNC manufacturing for medical imaging technologies.

Conclusion

In summary, precision CNC machining plays an indispensable role in the production of advanced medical imaging devices. From CT scanners to MRI machines and ultrasound systems, this intricate method ensures high-precision, reliability, and efficiency that these devices necessitate.

In this article, we have highlighted several integral points. Firstly, precision is paramount when it comes to machinery dealing with human lives and health – a realm where there’s no room for errors. With its precise manufacturing capability, CNC machining makes this possible. Secondly, besides accuracy, it also offers speed and repeatability, enabling mass production without sacrificing quality. Lastly, we’ve looked into how this technology simplifies complex procedures, making the development and manufacture of sophisticated medical imaging machinery feasible.

To illustrate, think of an ultrasound device with numerous intricate parts made through conventional methods which are time-consuming and prone to inconsistencies. Here, CNC machining steps in by creating these tiny components consistently every single time, taking less time and circulating zero possibility for dismissible errors – amplifying, thus, the usability and functionality of such pivotal healthcare apparatuses.

This discussion underscores the relevance of precision CNC machining in shaping the present and future of not just the medical industry but also human health per se. Furthermore, as we move forward into an era of technological advancements paired with increasing medical necessity, this process will only become more crucial.

Other Articles You Might Enjoy

- The Role of Bead Blasting in CNC Machining (bead blasting Steward)

Bead blasting is a commonplace aspect of numerous manufacturing procedures, including Computer Numerical Control (CNC) machining. Whether it's to enhance the external aesthetics or improve internal functionalities, bead blasting plays…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Nickel Alloys in CNC Machining: Inconel 718 vs. Monel K-500 for Aerospace and Marine Applications?

Introduction to CNC Machining and Nickel Alloys Computer Numeric Control (CNC) machining is a pivotal process in the manufacturing industry, using pre-programmed computer software to dictate the movement of factory…