The Role of Surface Finishes in CNC Machining: Anodized Aluminum vs. Stainless Steel

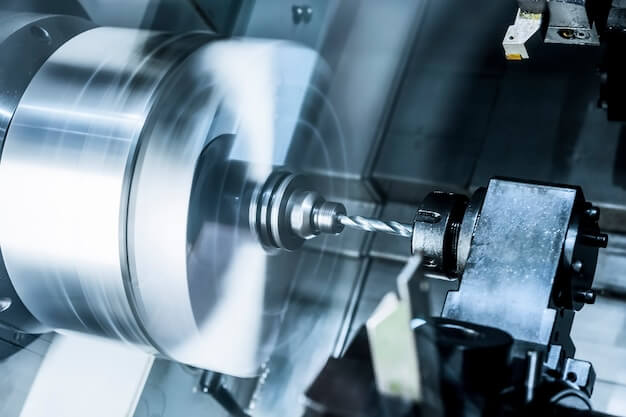

CNC machining, standing for Computer Numerical Control, represents a prevalent technology used in the manufacturing sector where pre-programmed software dictates the movement of machinery tools. With its enviable precision, speed, and repeatability, it plays a vital role in producing metal parts with detailed features and complex geometries. However, to not undermine these machined elements’ durability and aesthetic appeal, equipping them with appropriate surface finishes becomes imperative.

- Surface finish in CNC machining enhances a part’s cosmetic appearance by providing items like glossy or matte finishes, coloured or clear coats, etc., making products attractively market-ready.

- Surface finishing can provide corrosion resistance which aids in prolonging the life span of components, particularly useful with corrosion-prone material such as aluminum.

- Surface finishes also improve wear resistance; essential in high friction applications avoiding premature wearing out of parts thereby increasing their operational lifespan.

In essence, while CNC machining delivers precision parts, the subsequent surface finishes enhance endurance and visual treat transforming raw milled/aluminum/stainless steel pieces into final usable products that comply with all required industry specifications.

Understanding Anodized Aluminum

Anodization refers to an electrochemical process that alters the surface of metal parts, such as aluminum, to create a durable and corrosion-resistant finish. The typical aluminum component becomes anodized through a method known as sulfuric acid anodizing. This involves immersing the item in a solution containing sulfuric acid and applying an electric current resulting in the conversion of the surface layer into aluminum oxide, providing the part with outstanding resistance against wear and heat damage.

The predominant advantage of utilizing anodized aluminum in CNC machining is the production of highly durable parts marked by impressive heat tolerance levels. For instance, due to its sturdy exterior layer, anodized aluminum effectively withstands high temperatures often required in various manufacturing procedures without suffering any significant degradation or loss of integrity.

However, despite its numerous benefits, using anodized aluminum comes with certain limitations. One significant drawback is that it cannot be applied to metals other than aluminum. Hence, manufacturers who work with a variety of metallic substances need to find suitable alternative solutions for achieving similar levels of durability and heat resistance where needed.

Understanding Stainless Steel in CNC Machining

Stainless steel is widely used in CNC machining due to its corrosion resistance, formability, and high tensile strength. It is commonly used in manufacturing pump shafts, sheathing, screws, bolts, and household equipment.

Comparison Between Anodized Aluminum and Stainless Steel

The performance of surface finishes in CNC machining essentially depends on their application. When comparing anodized aluminum with stainless steel, each has its distinct advantages.

- Anodized aluminum offers a corrosion-resistant finish that lends it greater durability under harsh conditions, making it an ideal choice for outdoor equipment or marine applications. Additionally, the anodizing process allows for color variation which can enhance the aesthetic appeal of finished products.

- On the other hand, stainless steel is noted for its high strength and resistance to heat and chemicals. This makes it preferable in industries like healthcare and cooking where cleanliness and sterility are critical.

Despite these benefits, both materials have possible downsides based on the manufacturing need.

- Anodized aluminum, while durable and attractive, may be more costly and time-consuming to produce than untreated alternatives.

- Stainless steel’s hardness can pose difficulties during the machining process by wearing out tooling quicker. It also tends to be heavier and higher-priced compared to aluminum.

To conclude, recognizing the pros and cons of anodized aluminum and stainless steel ensures optimal material selection aligned with specific manufacturing needs.

Other Articles You Might Enjoy

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining: The Role of Stainless Steel and Aluminum Computer Numerical Control (CNC) machining is a groundbreaking method in manufacturing that involves precise computer commands to manipulate and control tools…

- Enhancing Aesthetic Appeal in CNC Machining: Anodized Aluminum vs. Painted Steel

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a high-precision manufacturing process that uses pre-programmed computer software to direct the movement of complex machinery tools. This technological approach…

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining and the Importance of Material Selection CNC machining, a pivotal manufacturing process in numerous industries, uses pre-programmed computer software to dictate the movement of factory tools and machinery.…