Introduction to Online CNC Machining Services: Ensuring Quality and Timeliness

In the world of online services, Computer Numerical Control (CNC) machining stands out due to its precise, automated manufacturing process.

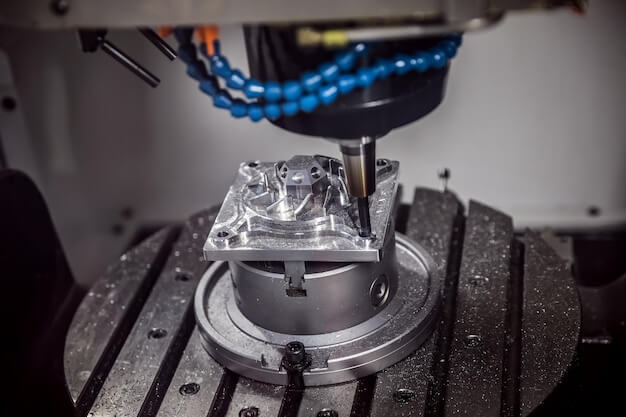

Online CNC machining is a subtractive manufacturing process that utilizes computerized controls to eliminate layers of material from a block, termed as the ‘workpiece’, to design the end product. This technology-centric production method rapidly fabricates hardware parts with pinpoint precision, irrespective of how intricate or simple the design is.

The importance of maintaining high quality and timeliness cannot be overemphasized in this context. Superb quality signifies compliance with predefined specifications and meeting customer expectations about accuracy and finish. Meanwhile, ensuring timeliness translates to on-time delivery which prevents operational disruptions and enhances overall client satisfaction.

- To ensure top-notch quality, vigilance during the process stages is necessary alongside meticulous final inspections.

- For timely deliveries, effective workflow management, proper resource allocation, contingency planning, and regular monitoring are crucial.

Understanding Online CNC Machining Services

CNC machines (Computer Numerical Control) are automated devices that interpret and execute programmed commands to perform complex manufacturing tasks with precision. These machines make use of CAD/CAM software programs which convert digital design inputs into numerical instructions, guiding the operating tools of the machine. The simplified function of a CNC machine would follow three main steps: designing the part in a CAD program, converting the CAD file to a CNC machinable format using a CAM system, and finally executing the part’s creation based on these translated instructions. Among its many benefits, CNC machining services provide rapid high-precision production, material versatility, and is highly significant across several sectors.

- Automotive: To manufacture accurate car parts out of raw materials.

- Aerospace: For creating intricate parts of air crafts.

- Military: Requiring exact specifications for their equipment.

- Healthcare: In producing medical devices or components.

To ensure quality and timely delivery when availing online CNC services, one needs to pay attention to choosing providers with proven track records, meeting industry standards, clear communication channels, quick turnaround times and comprehensive post-production inspections.

Understanding and Ensuring Quality in Online CNC Machining Services

When it comes to ensuring quality in online CNC machining services, it’s important to consider the following:

- Utilizing precision machining services to achieve the desired level of accuracy and quality for your machined parts.

- Partnering with a CNC service provider that offers a wide range of capabilities, including CNC milling and CNC turning, to meet diverse manufacturing needs.

Guaranteeing Timeliness in Delivery of CNC Machining Services

Timely delivery is an essential expectation in the field of online Computer Numerical Control (CNC) machining services. To parse ‘timeliness’, it refers to an on-schedule completion and delivery of orders, ensuring customer satisfaction and retention. Three crucial strategies contribute towards this goal: having appropriate resources, implementing efficient process flow, and adopting proactive planning.

- Adequate Resources: Ensuring sufficient resources at hand directly affects the speed of production—a necessary aspect when meeting deadlines. Available staff, accessible raw materials, and well-maintained machinery not only increase productivity but also help foresee potential hurdles that could cause delays.

- Efficient Process Flow: An example of effective process flow involves optimizing procedures like automated tool changes or using adaptive software for more streamlined operations. The benefits include consequential reduction in manual intervention, minimization of errors, and increased output pace leading to punctual deliveries.

- Proactive Planning: Upfront preparation incorporates anticipating possible challenges and formulating contingency plans. This step includes regular equipment maintenance schedules, timely restocking of supplies, and adjusting workforce based on projected demands. Proactive planning’s primary benefit is its contribution to preventing unexpected disruptions thereby facilitating consistent and reliable service delivery timescales.

In conclusion, timely delivery in online CNC machining relies heavily upon the precision application of these key strategic principles. All three—adequate resourcing, efficient processing, and proactive planning work synergistically. By exercising such stringent controls, providers can assure quality services right as per agreed timetables.

Effectively Balancing Quality and Timeliness in Online CNC Services

While scouting for an online CNC service provider, it is crucial to find a balance between quality and timeliness. Achieving this balance ensures that you get superior products within your project’s timeline without compromising either aspect. A simple checklist can help streamline the process of evaluating prospective providers.

- Product Quality: Look out for aspects like precision, finish, and durability. Evaluating previous work samples or customer testimonials can offer insights into their quality standards.

- Turnaround Time: Make sure the provider can meet your project deadlines. Quick response time, efficient processes, cutting-edge technology, and sufficient manpower contribute to timely delivery.

- Certifications and Compliance: Certifications such as ISO confirm adherence to global quality norms. This results in reliable output that meets standardized industry specifications.

- Technical Support and Customer Service: Round-the-clock technical assistance and easy-to-understand communication contributes significantly towards troubleshooting issues promptly, preventing delays.

In conclusion, tracking these parameters effectively will ensure that you engage with a competent online CNC machining services provider yielding high-quality products on time every time.

Other Articles You Might Enjoy

- Understanding The Functionality of Cantilever Snap Joints( Linda)

A cantilever snap joint, also known as a snap fit, is a critical component regularly used in countless mechanical and electronic applications. This type of fastening device does not require…

- The Functionality of Cantilever Snap Joints in CNC Machining(how does a cantilever snap joint work Rory)

The Functionality of Cantilever Snap Joints in CNC Machining The functions of cantilever clamp joints in CNC machining include several aspects: Positioning and Fixation: Cantilever clamp joints effectively position and…

- Titanium CNC Machining: Advantages and Challenges in Aerospace and Medical Industries

Introduction to Titanium CNC Machining and its Significance in Aerospace and Medical Industries Titanium Computer Numerical Control (CNC) machining utilizes advanced computer systems to control and monitor the movements of…