Transforming Architecture with CNC Machined Aluminum Facades

CNC machined aluminum facades are a significant innovation in the architectural industry due to their innovative design, structure, and aesthetics. Through a process known as Computer Numerical Control (CNC), precise and high-quality cuts on aluminum materials are achieved, creating intricate and customizable designs that greatly enhance building façades. Key reasons behind this growing preference include:

- Durability: Aluminum is robust and resistant to corrosive elements, making it capable of maintaining its quality despite harsh weather conditions.

- Precision: With CNC machining, architects achieve exact dimensions, thereby eliminating errors commonly associated with manual handling.

- Versatility: This method allows easy alteration and customization according to different architectural needs.

The aforementioned factors significantly contribute towards making CNC machined aluminum facades an increasingly popular choice amongst today’s architects.

Understanding CNC Machine Technology:

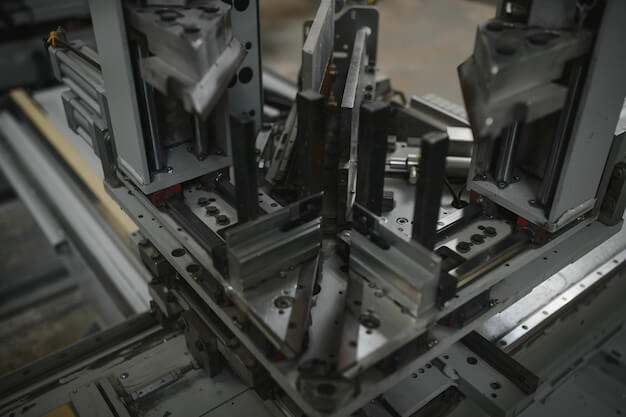

- CNC machine technology encompasses advanced techniques and processes that enable precise and efficient material removal and shaping.

- It involves the utilization of computer-controlled systems to execute complex machining operations with high accuracy and repeatability.

- Modern CNC machines integrate cutting-edge technologies to optimize production processes and enhance the overall manufacturing efficiency.

- Exploring CNC machine technology requires collaboration with experienced service providers offering precision machining services to ensure optimal results.

Understanding Components of CNC Machined Aluminum Facades

The application of aluminum in CNC machined facades is prominent due to its coveted properties. Strong yet lightweight, aluminum provides durability and ease-of-manufacture to the complex designs of architectural facades. It is capable of withstanding various weather conditions while maintaining its aesthetic appearance, contributing to a building’s visual appeal as well as its structural integrity.

Consequently, CNC machines often utilize aluminum because it responds extremely well to machining processes. Specific benefits include:

- High Speed Machining: As a softer metal, aluminum facilitates quicker feed rates resulting in faster production times.

- Versatility: The malleability of aluminum allows for intricate design possibilities, hence increased design versatility on facades.

- Tolerance: CNC-machined aluminum components possess high degree of precision and tight tolerances, essential in creating structurally sound, seamless facades.

- Cost-effective: Lastly, compared to other materials such as steel or titanium, aluminum is less expensive leading to significant cost savings without compromising quality.

Applications of CNC Machined Aluminum Façade in Architecture

The use of CNC machined aluminum façades has significantly redefined architectural standards and practices. The flexibility it offers architects and designers is seen in a variety of contemporary buildings – take for instance, the intricately designed Art Museum of China’s Lingang district that features lightweight CNC-machined aluminum paneling optimized to mimic gentle waves symbolic of its hosting city. Furthermore:

- The modern building techniques utilizing this technology promotes design versatility by allowing complex patterns and shapes that would otherwise be challenging with traditional methods.

- This method cannot only replicate traditional craftsmanship but also create bespoke designs improving aesthetic quality while reducing manual labor and time invested.

- In terms of sustainability, the use of recycled aluminum paired with CNC machining proves a highly sustainable choice – as an example, Apple’s Cupertino Headquarters boast a seamless façade comprising 805,000 square feet of custom extruded and mechanically textured cladding sustainably built from recycled aluminum. In addition to being recyclable, aluminum facades are noted for their durability and resistance to environmental impacts ensuring lower maintenance costs and longer lifespan.

As these examples illustrate, the application of CNC machined aluminum facades undeniably expands architectural possibilities – impacting design flexibility, affordability, and sustainability positively.

Advantages of CNC Machined Aluminum Facades

The use of CNC machined aluminium facades in architecture not only adds aesthetic appeal but also offers significant functional advantages. One of the major durability benefits of these facades is their exceptional weather resistance. The machining process on aluminium uses Computer Numerical Control (CNC) technology to create precision-cut panels that withstand a variety of climatic conditions, ensuring longevity and reducing maintenance costs.

- Aesthetic Appeal: These facades boast clean lines and a modern look. They can be customized according to design requirements, offering architects and designers vast creative flexibility. The precise control offered by CNC machines allows for intricate designs which contribute to unique and visually appealing architectural structures.

- Durability: In addition to providing a contemporary aesthetic, CNC machined aluminum facades are specifically designed to endure harsh environmental elements. Their superior strength-to-weight ratio contributes to their robustness, thereby meaningful enhancing building durability.

In conclusion, CNC machined aluminium facades are an optimal choice for both aesthetically pleasing and enduring architectural solutions.

Challenges in Implementing CNC Machined Aluminum Façades in Architecture

In the architectural field, implementation of CNC machined aluminum façades often encounters several challenges. One common problem is during installation where precision fitting can be difficult due to measurement discrepancies or unpredictable site conditions. Moreover, complex façade designs may pose additional hindrances due to intricate details that are challenging to replicate precisely using machining tools. These shortcomings call for intervention from skilled professionals which could raise labor costs.

- Cost implications: Compared to traditional methods such as hand-cutting and assembly, CNC machined facades often come with higher initial costs. This accounts not only for purchasing state-of-the-art CNC equipment but also for training personnel and retrofitting workspaces to accommodate these machines. However, it’s important to consider the potential long-term savings as well – continuous operation with fewer errors means lesser waste, less rework and a more efficient production process over time.

Case Study: A Successful Application of CNC Machined Aluminum Facade

The Institute for Advanced Architecture, Catalonia (IAAC) represents an innovative application of a CNC machined aluminum facade. IAAC’s Endesa Pavilion project overcame the challenge of achieving functional yet aesthetically pleasing solar architectures by using a parametric model and this advanced machining technology. The Pavilion’s open-source software designed the unique geometric patterns that would optimize shading tactics according to times of daylight. Then, via use of a CNC milling machine, these designs were cut into thick expanded aluminum sheets to create façades with optimal passive solar control.

- Detailed Account: Multiple panels were meticulously carved and assembled, showcasing the precision offered by the CNC process. This method not only sped up production time but also minimized error margins creating perfect fits every time.

- Impact and Reception: Post implementation, the project received wide acclaim at the 2011 Smart Geometry conference; it was celebrated for its marriage of design optimization and sustainable practices. It demonstrated how CNC machining can reimagine architectural aesthetics while emphasizing energy efficiency.

Conclusion: The Impact and Future of CNC Machined Aluminum Facades in Architecture

In conclusion, the incorporation of CNC machined aluminum facades brings about immense value in transforming architecture. These innovative facades offer endless design capabilities due to their flexibility and preciseness, enabling architects to push boundaries and create structures that are visually striking and structurally robust. Moreover, being lightweight yet durable, these facades contribute to sustainable building practices.

Looking forward, the application of CNC machined aluminum facades holds significant prospects for the architectural sphere. With advancements in technology allowing for increasingly refined machining processes, they’ll not only streamline construction but also lay the groundwork for a new age of creative freedom in architectural design. This blend of practicality and innovation underscores their indispensable role in shaping the future landscape of architecture.

Understanding CNC Machined Aluminum Facades

The application of Computer Numerical Control (CNC) machineries within the architectural sphere, specifically in creating aluminum facades, can be quite complex for individuals unfamiliar with manufacturing processes. One main challenge could be comprehending heavy technical terminologies and jargons related to CNC machines and their architecture applications. This confusion often stems from a lack of clarity about basic terms such as ‘facade’, which in this context refers to the exterior or outer face of a building. Similarly, some users struggle to understand what exactly is meant by ‘CNC machining’. Using simple language: CNC machining involves using computers to control machine tools including drills and lathes that shape raw materials like aluminum into precise parts.

- Facade: The exterior or outer face of a building.

- CNC Machining: A process that involves using computers to control machine tools which then help to create specific shapes or designs from various kinds of raw materials such as metal.

To enhance comprehension, it’s essential to break down each component involved in CNC machined aluminum facades and its function. For example, the role of Aluminum in these constructions involves providing longevity due to its resistance towards different weather conditions.

Other Articles You Might Enjoy

- Tool Steel Grades for CNC Machining: D2 vs. A2 - A Comparative Study?

Introduction to CNC Machining and Tool Steel CNC machining, or computer numerical control machining, is a manufacturing method that employs pre-programmed software to direct the activity of factory tools and…

- Custom CNC Machining for High-Tech Security Systems

Introduction to CNC Machining for High-Tech Security Systems Custom Computer Numerical Control (CNC) machining plays an integral role in the production of high tech security systems. It is a manufacturing…

- Plastic vs. Metal CNC Machining: A Detailed Comparison?

CNC Machining: An Essential Process Across Industries Computer Numerical Control (CNC) machining is a digital manufacturing technology that makes use of pre-programmed computer software to dictate the movement of various…