Bead blasting is a crucial process within the realm of Computer Numerical Control (CNC) machining. It’s an integral operation that gives metal parts their final polished appearance ready for use across various industries.

So, what exactly does bead blasting involve? How does it contribute to the overall production cycle in CNC machining? Let’s delve deeper into this fascinating process and see how CNC machinery utilizes it to produce high-quality precision components.

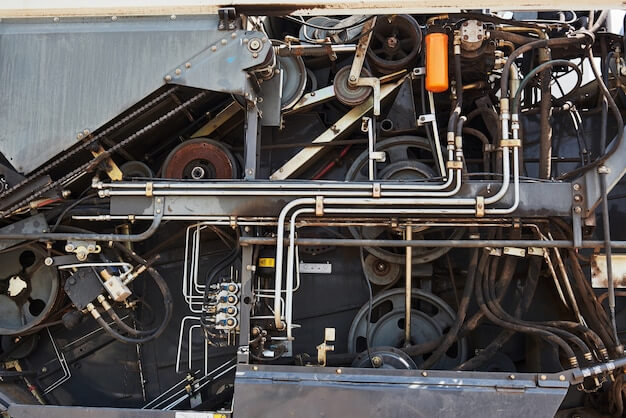

Bead blasting is a form of surface finishing used in CNC machining to provide a smooth finish on metal surfaces by removing impurities or making specific surface alterations. As the name suggests, it involves projecting small glass beads at high pressure towards the surface of a workpiece via a specialized machine.

Here’s how this innovative process plays out:

Step 1: Positioning

The first step in bead blasting involves accurately positioning the required component onto the bead blasting machine. The part needs to be secured correctly to prevent any movement during the blasting process since such movements can result in uneven finishes.

Step 2: Blasting Process

Once properly positioned, the machinist initiates the bead blasting procedure. Small glass beads are projected against the metal component with extreme force, sufficient enough to polish imperfections away. This is done following a carefully planned pattern to ensure every part of the component receives equal treatment.

Step 3: Finishing

After all sections have been blasted, they are inspected to ascertain if the desired finish level has been achieved. If necessary, additional blasting sessions might be carried out until the expected level of quality is obtained.

These steps make up the standard method for bead blasting as performed within the confines of CNC machining environments. However, processes might differ slightly depending on variables such as component size, complexity, material, or end-use requirements.

Why Use Bead Blasting?

There are many benefits of employing bead blasting in CNC machining. Some of these include:

1. Enhanced Finishing: It allows for a much smoother and uniform finish, improving the aesthetics of the final product.

2. Precision: By using high-tech machinery, bead blasting achieves the utmost accuracy, treating even intricate components without causing any deformation.

3. Increased Lifespan: Bead blasting can eliminate corrosion or rust on metal components, increasing their durability and lifespan.

4. Cost-Effective: As compared to other finishing methods such as sanding or grinding, bead blasting is often more cost-effective since it requires fewer resources and less labor.

CNC machines that feature embedded bead blasting options offer manufacturers an all-in-one solution, eliminating the need for transferring parts to separate blasting facilities – thereby consolidating production times and reducing costs considerably.

So while it often goes unnoticed, bead blasting plays a critical role within the larger CNC machining process. From enhancing component finishes to extending the lifespan of parts, this advanced surface treatment technique offered by modern-day CNC machine tools significantly contributes to overall productivity levels across numerous industries.

In closing, when seeking CNC machining services, don’t forget about the kind of finishing your products might require. A smooth, polished piece achieved via bead blasting doesn’t just look good; it functions better and lasts longer too.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Precision CNC Machining Services: Reliable Solutions in Stainless Steel

Precision CNC Machining: An Essential Manufacturing Tool Precision CNC machining is a modern manufacturing process that uses detailed, digitized designs to guide complex machinery. Through the use of a Computer…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…