Precision CNC Machining for Medical Devices: Titanium and Stainless Steel

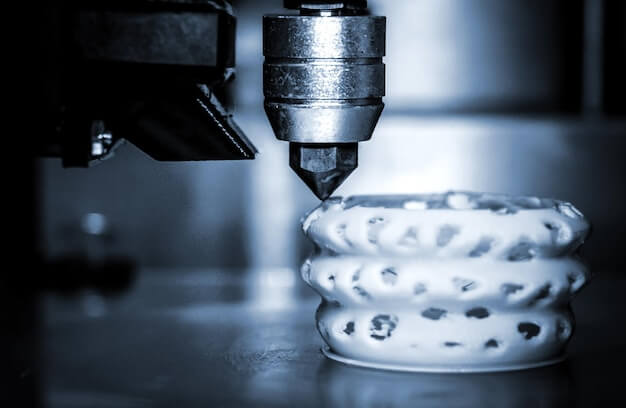

The field of CNC machining plays an essential role in the medical device industry. It involves programming computer software to dictate automated machinery movements, enabling high-speed, precision manufacturing with stringent quality control – a vital feature when producing lifesaving medical equipment or devices. This technology primarily uses materials such as titanium and stainless steel due to their excellent compatibility with human tissues and resistance against corrosion.

- Titanium, recognized for its strength and lightness, is often used for surgical implants including hip joints or dental substitutes.

- Stainless steel serves crucial functions in creating durable instruments like forceps, tweezers or hemostats.

Considering the exacting requirements in the sector, CNC machining not only streamlines production but also consistently ensures products’ methodical adherence to regulatory standards – exemplifying why this process holds pivotal importance in crafting highly reliable and efficient medical devices.

Understanding Precision CNC Machining and Its Working Process:

- Advanced Technology: Precision CNC machining utilizes advanced technology and computer programming to achieve high levels of accuracy and precision in the manufacturing of medical devices using materials such as titanium and stainless steel.

- Material Selection: The process involves careful material selection to ensure the desired properties and qualities of the final machined parts.

- Explore more about precision machining services here to experience the precision and quality offered by professional CNC machining services.

Precision CNC Machining in Medical Devices

The role of Precision Computer Numeric Control (CNC) machining, particularly in the medical space, lies at the heart of creating intricate and high-quality titanium and stainless-steel devices. Its application within healthcare equipment manufacturing has become an imperative due to the critical demand for accuracy and precision.

- Firstly, a minor margin of error could drastically affect device efficacy, causing potential risk towards patients’ health. Therefore, being accurate is essential in fabricating components like artificial joints or dental implants.

- Secondly, durability is another reason why precision is crucial. These components often face extreme stress and must withstand rigorous use without degrading. The advanced capabilities of precision CNC machining allow manufacturers to create strong, durable parts that meet stringent health industry specifications.

- Lastly, the specificity in minimally invasive surgical devices, cardiovascular devices and orthopedic implants requires extremely precise machining techniques which additionaly reassures smoother recovery phase as well respects bio-compatibility standards imposed by various health organizations globally.

In essence, this technology eliminates all possibilities of human fallibility associated with complex machinations thus prioritizing patient safety and ensuring longevity of the medical instruments beyond traditional methods.

Titanium in Medical Devices

Titanium is a metal known for its high strength-to-weight ratio, excellent corrosion resistance and impressive biocompatibility. Its unique properties make it ideal for use in medical device manufacturing. Unlike some other materials, titanium isn’t rejected by the body, which makes it an essential material for implants and prosthetics. This also means that devices made from titanium can remain within the human body for long periods without causing harmful effects.

For instance, titanium’s outstanding durability and lightweight nature have made it the preferred choice of material in creating orthopaedic implants such as hip and knee replacements. These attributes allow these implants to withstand immense pressure while mimicking the natural motion of the joints they’re replacing. Similarly, due to its non-magnetic property, titanium is used in constructing surgical tools and instruments utilized in MRI procedures. Furthermore, dental implants are another common application wherein titanium’s ability to fuse with bone through osseointegration helps patients regain optimal oral function.

- Orthopedic Implants: The strength and low weight of titanium make it suitable for hip and knee replacement.

- Surgical Instruments: Being non-magnetic, titanium doesn’t interfere with MRI procedures.

- Dental Implants: Titanium’s ability to bind with bone aids in oral restoration treatments.

Stainless Steel in Medical Devices

Characterized by unrivaled corrosion resistance, robust durability, and its ability to be sterilized repeatedly without any degradation of properties, stainless steel stands as a choicest material for many medical devices. Primarily composed of iron, alongside other elements such as carbon and chromium which fortify its resilience against rusting – these inherent attributes justify why it is extensively used in the healthcare equipment production sector.

This suitability extends to diverse applications such as:

- Surgical Instruments: Most surgical implements, from scalpels and scissors to forceps are crafted using this metal given its strength, versatility, and easiness in cleaning and sanitizing. It also doesn’t react adversely with bodily fluids making it apt for operations.

- Orthopaedic Implants: The non-corrosive nature coupled with high mechanical values make stainless steel an ideal candidate for manufacturing implants including artificial hip/knee joints or plates/screws for bone fixations.

- Dental Tools: Dental probes, mirrors and scalers preferentially use stainless steel due to its likelihood in preventing bacterial growth and transmission owing to its smooth texture.

Comparison between Titanium and Stainless Steel for Medical Devices

In the medical industry, precision CNC machining has increasingly utilized both titanium and stainless steel for their unique sets of advantages. The ability to withstand high heat and pressure makes stainless steel a suitable choice for general rectification tools and orthopaedic joint replacements. Additionally, its corrosion-resistance and affordability give it an edge in many use cases. However, stainless steel can be prone to wear-and-tear over time.

- Titanium’s main advantage is its biocompatibility which reduces the risk of rejection by the human body, making it ideal for long-term implants such as pacemakers or bone screws. It also has an excellent strength-to-weight ratio, highlighting its suitability for weight-sensitive applications.

- But on the flipside, titanium tends to be significantly more expensive than stainless steel and requires specialized machinery for shaping due to its robustness.

The preferences for these materials ultimately depend on the intended application, balancing factors such as cost-effectiveness, durability, and patient safety.

Other Articles You Might Enjoy

- The Role of Bead Blasting in CNC Machining (bead blasting Steward)

Bead blasting is a commonplace aspect of numerous manufacturing procedures, including Computer Numerical Control (CNC) machining. Whether it's to enhance the external aesthetics or improve internal functionalities, bead blasting plays…

- Custom CNC Machining for Industrial Automation Solutions

Introduction to Custom CNC Machining and Industrial Automation Solutions Custom Computer Numerical Control (CNC) machining is a precision-manufacturing process in which pre-programmed computer software dictates the movements of factory machinery…

- Navigating the Challenges of Bead Blasting Techniques in CNC Machined Bearing Housings

The Complexity of CNC Machined Bearing Housings The manufacturing of CNC machined bearing housings involves intricate processes that demand high precision and meticulous attention to detail. These components are critical…