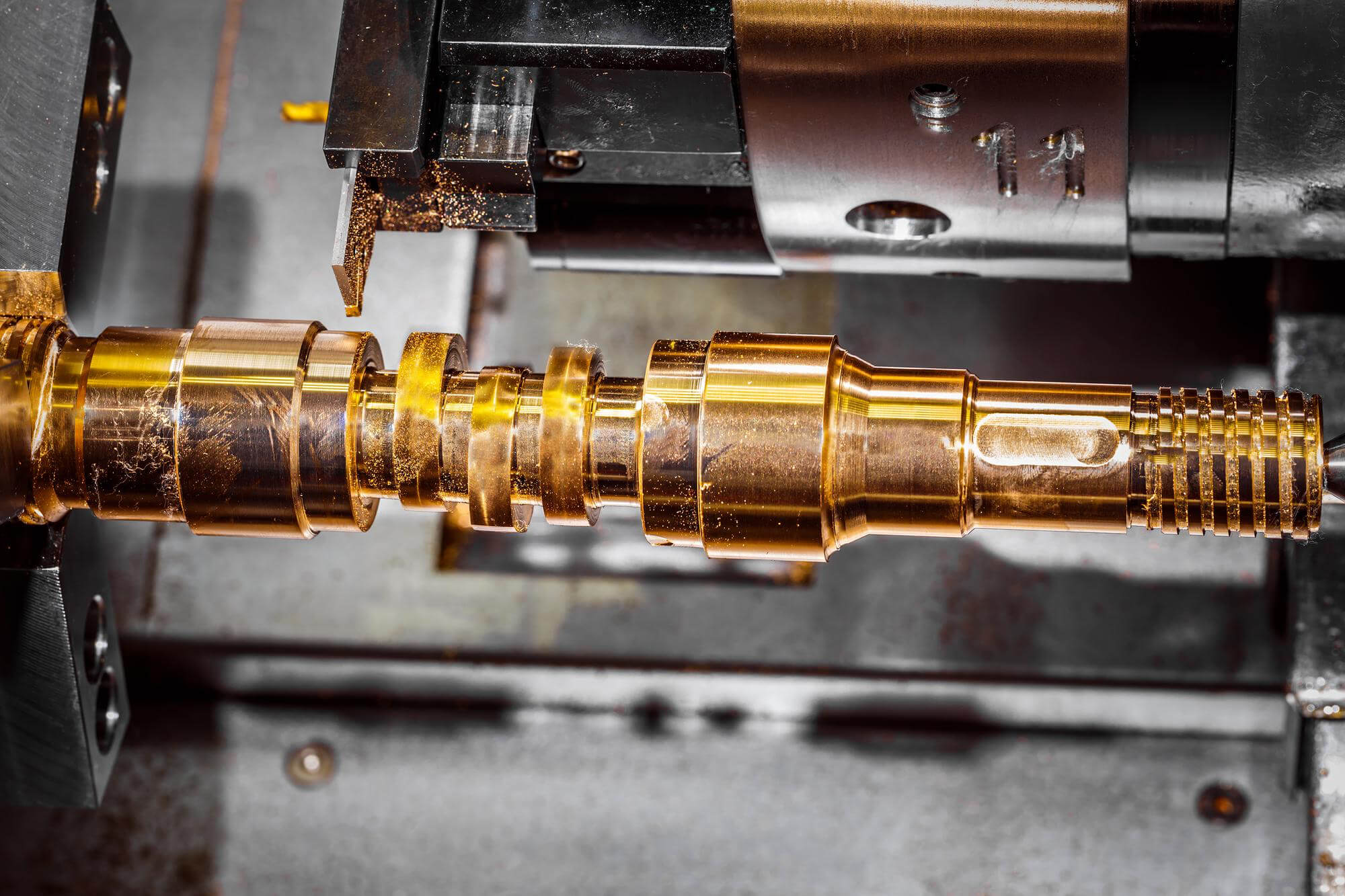

When it comes to CNC machining, thread insertion methods are crucial for ensuring high-quality results. Different approaches to thread insertion can significantly impact the efficiency, durability, and precision of the final product. Let’s dive into the fascinating world of thread insertion in CNC machining parts and explore the various methods and their unique advantages.

The Importance of Thread Insertion Methods

Thread insertion is an essential step in CNC machining. It involves the process of threading a tool into the material to create precise screw threads. The accuracy and quality of these threads are vital for the performance and reliability of the machined part. There are two primary methods for thread insertion: radial insertion (also known as direct or straight insertion) and compound insertion (also known as angular or lateral insertion).

Radial Insertion Method

Radial insertion is a straightforward approach where the threading tool moves perpendicularly to the spindle axis. This method is often used for materials like copper and aluminum, which are softer and more forgiving. The key advantages of radial insertion include simplicity and ease of programming. However, this method can cause higher tool wear and heat generation, especially with harder materials.

In the G76 single-line threading cycle, radial insertion is specified using the parameter A0. For dual-line threading cycles, the last two digits of the P parameter in the first block are set to 00.

Compound Insertion Method

Compound insertion, on the other hand, involves moving the threading tool at an angle, typically less than the thread’s side angle. This method reduces the cutting load on the tool and allows for deeper cuts, resulting in fewer passes to complete the thread. The compound insertion method is beneficial for tougher materials and provides better tool life and thread quality.

To achieve compound insertion, a slight adjustment in the programming angle is required. For example, for a 60° V-thread, setting the insertion angle to 29° creates a 1° clearance on the back side of the tool. This adjustment helps in managing heat dissipation and reduces the risk of tool wear.

Programming the Insertion Methods

The choice between radial and compound insertion methods can be influenced by the material, thread type, and desired finish. The G76 cycle in CNC programming is flexible and can accommodate both methods. In the older Fanuc controllers, the single-line cycle uses the A parameter, while the newer dual-line cycle requires setting the P parameter to reflect the desired insertion method.

Advanced Insertion Techniques

Beyond the basic radial and compound methods, there are advanced techniques like single-sided cutting and zigzag cutting. These methods further refine the thread cutting process, allowing for better control over the cutting load and resulting in high-quality threads.

Single-Sided Cutting:

- Maintains a constant cutting volume

- Ideal for applications requiring precise control over the cutting load

Zigzag Cutting:

- Utilizes both cutting edges

- Suitable for applications where material removal rate is crucial

Practical Examples and Data

To illustrate the impact of different thread insertion methods, let’s consider a practical example involving the threading of a 7075-T7351 aluminum alloy. This material is known for its strength and machinability, making it an excellent candidate for demonstrating thread insertion techniques.

Example Data:

| Method | Material | Insertion Angle | Cutting Depth per Pass | Tool Life (cycles) | Thread Quality |

|---|---|---|---|---|---|

| Radial Insertion | Aluminum | 0° | 0.5mm | 1000 | Good |

| Compound Insertion | Aluminum | 29° | 1.0mm | 1500 | Excellent |

| Single-Sided Cutting | Aluminum | 0° | 0.3mm | 800 | Fair |

| Zigzag Cutting | Aluminum | 0° | 0.4mm | 1200 | Very Good |

Conclusion

Thread insertion methods play a vital role in CNC machining, impacting tool life, thread quality, and overall efficiency. By understanding the nuances of radial and compound insertion, as well as advanced techniques like single-sided and zigzag cutting, machinists can optimize their processes for better results.

Other Articles You Might Enjoy

- Mastering Thread Tapping in CNC Machining Parts

Thread tapping is one of the most common hole machining operations on CNC machining centers, right after drilling. Due to its widespread application in many milling operations, most control systems…

- Unlocking the Secrets of CNC Machining Parts with Spindle Rotation Control

CNC machining is a blend of art and science, and mastering spindle rotation control can significantly enhance the quality and efficiency of machining parts. Whether you're working with a CNC…

- Requirements for CNC Machining Parts

Preparation Work Complete the necessary preparation before machining, including process analysis, process route design, tool and fixture selection, and program compilation. online cnc machining service Operating Steps and Contents Start…

- Face Milling Essentials for CNC Machining Parts

Face milling is an essential operation in CNC machining, aimed at controlling the height of the workpiece and ensuring a smooth surface finish. This process often uses multi-tooth cutters, known…

- What are the requirements for CNC machining of bearing parts?

Bearings are common and important parts in the automotive industry, which can support transmission components and transmit torque. Generally, CNC machining centers are used to process bearing parts. So what…

- Evolution of Mills and Machining Centers: The Future of CNC Machining Parts

Stepping into the world of CNC machining, you quickly realize how pivotal mills and machining centers are in crafting precise parts. Over time, these machines have evolved significantly, transforming from…