In CNC machining, precision and efficiency are crucial. For engineers working on complex parts, choosing the right lathe tools is essential. When dealing with intricate shapes, deep holes, or thin-walled components, lathe tools need to be not only accurate but also tough and versatile. This guide explores how to make the best use of lathe tools in CNC machining for complex parts, covering important aspects like selecting the right tools, understanding tool geometry, choosing the right materials and coatings, and optimizing the tool path for better results.

How to Select the Right Lathe Tools for CNC Turning

When dealing with complex parts, the right lathe tool can be the difference between success and failure. Selecting the appropriate tool involves considering several key factors: material of the workpiece, tool geometry, the required precision, and the desired surface finish.

Workpiece Material and Tool Selection

Different materials require different cutting approaches. Here’s a quick overview of common materials and their corresponding lathe tools:

| Material | Lathe Tool Material | Tool Coating | Notes |

|---|---|---|---|

| Steel | Carbide, HSS | TiN, TiAlN | Strong wear resistance required |

| Aluminum | Carbide | Diamond-like Carbon | High-speed, low wear tool needed |

| Stainless Steel | Ceramic, Carbide | TiCN | Requires high heat resistance |

| Titanium | Carbide | TiAlN, AlTiN | Hard materials, prone to tool wear |

| Brass | HSS | N/A | Relatively easy to machine |

Tool Geometry

The geometry of the lathe tool plays a crucial role in machining complex parts. Engineers should pay close attention to the following parameters:

- Rake angle: Affects the cutting forces and chip flow. Positive rake angles are more suitable for softer materials like aluminum, while negative rake angles are better for tougher materials like stainless steel.

- Nose radius: A larger nose radius improves surface finish but increases cutting forces, which can be problematic in thin-walled parts.

- Clearance angle: Prevents the tool from rubbing against the workpiece. It must be optimized for the specific material being machined to minimize wear.

Balancing Precision and Efficiency

For complex geometries, precision is essential. Engineers must ensure that the lathe tool can maintain tight tolerances while also minimizing cycle times. Multi-axis CNC machines allow for intricate cutting paths, but the tool must be capable of enduring the stresses of high-speed cutting.

Impact of Lathe Tool Geometry on CNC Cutting Performance

Tool geometry is often the deciding factor in achieving both efficiency and accuracy in complex part production. The shape and configuration of a lathe tool determine how it interacts with the material and the overall cutting performance.

The Importance of Rake and Clearance Angles

The rake angle impacts chip formation and the overall cutting forces. For example, a positive rake angle allows for smoother cutting and is best suited for soft materials like aluminum, where chip flow is critical to avoid clogging the tool. On the other hand, negative rake angles are ideal for hard materials, providing greater tool strength.

The clearance angle ensures the cutting edge stays sharp by reducing contact between the tool and the workpiece, which can lead to friction and heat buildup. This is particularly important for complex parts with narrow tolerance requirements, where any deviation from the specified path could compromise part quality.

Effects on Surface Finish and Part Integrity

The nose radius of the tool has a significant influence on surface finish. For finishing operations, a larger nose radius can be beneficial as it produces a smoother surface, but it must be carefully controlled to avoid excessive cutting forces that can distort thin-walled parts. For roughing operations, a smaller nose radius is preferred for removing material more efficiently.

3. Optimizing and Extending Lathe Tool Life in CNC Turning

In CNC machining, maximizing tool life is essential for maintaining production efficiency and reducing costs. Engineers must carefully select tool materials and coatings to ensure durability, especially when machining complex parts.

Lathe Tool Materials

| Tool Material | Best For | Limitations |

|---|---|---|

| High-Speed Steel (HSS) | Versatile, good for low-speed cutting | Limited wear resistance |

| Carbide | Hard materials, high-speed cutting | Prone to chipping under heavy loads |

| Ceramic | High heat resistance | Brittle, expensive |

| Cubic Boron Nitride (CBN) | Ultra-hard materials | Extremely expensive |

Tool Coatings

Tool coatings enhance performance by reducing friction, heat, and wear. Common coatings include:

- TiN (Titanium Nitride): Improves hardness and oxidation resistance.

- TiAlN (Titanium Aluminum Nitride): Performs well in high-heat applications like stainless steel and titanium machining.

- Diamond-like Carbon (DLC): Reduces friction in softer materials like aluminum, preventing chip build-up.

Reducing Tool Wear

To prolong tool life, it’s essential to minimize wear by optimizing cutting parameters. Factors like cutting speed, feed rate, and depth of cut must be carefully balanced. For instance, high cutting speeds might shorten tool life, especially in harder materials like stainless steel or titanium.

Optimizing Lathe Tool Path and Cutting Parameters in CNC Programming

CNC programming plays a pivotal role in determining the efficiency of lathe tool use. Engineers must optimize the tool path to reduce cycle time, minimize tool wear, and ensure precision.

Tool Path Strategies for Complex Parts

For complex parts, tool path optimization is critical to avoid unnecessary tool changes and re-positioning. Multi-axis CNC machines offer flexibility, but the tool path must be carefully planned to maximize material removal without sacrificing surface quality.

Cutting Parameters: Speed, Feed, and Depth of Cut

The cutting speed, feed rate, and depth of cut directly impact tool wear and machining time. For example, when machining hard materials like titanium, it’s essential to lower the cutting speed and increase the feed rate to prevent excessive heat buildup.

| Material | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

| Aluminum | 150 – 300 | 0.1 – 0.2 | 1 – 3 |

| Stainless Steel | 30 – 80 | 0.08 – 0.15 | 0.5 – 1 |

| Titanium | 20 – 60 | 0.05 – 0.1 | 0.3 – 0.8 |

Reducing Tool Changes

For complex parts, reducing tool changes is essential for maintaining efficiency. Engineers can use modular tooling systems that allow quick changes between roughing and finishing tools without disrupting the production flow.

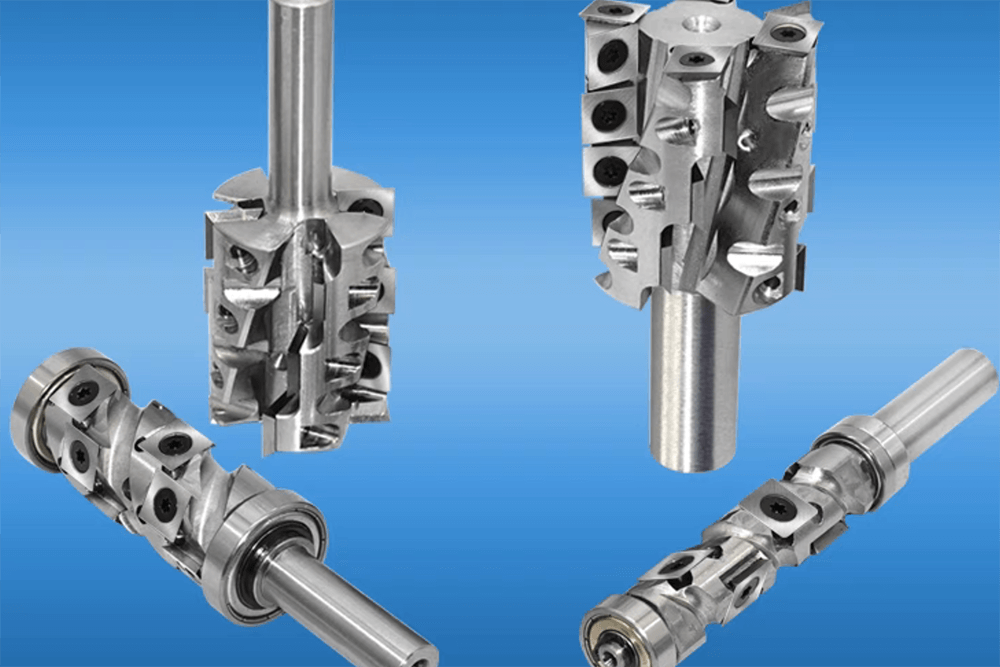

Application of Lathe Tools in Complex Part Machining

Complex part machining often requires specialized lathe tools to meet the challenges of intricate geometries, deep bores, and thin-walled sections. Engineers must carefully choose the right tools and apply optimized strategies to ensure both precision and efficiency in the machining process.

Deep Bore Machining: Challenges and Solutions

Machining deep bores presents significant challenges due to the increased likelihood of tool deflection and the difficulty in chip evacuation. As the depth of the bore increases, the cutting tool becomes more susceptible to vibrations, which can negatively impact dimensional accuracy and surface finish. These vibrations, combined with the challenges of chip removal, can also lead to overheating, which reduces tool life.

To address these challenges, engineers can use the following strategies:

- Long-reach lathe tools: These tools are specifically designed to provide stability when machining deep bores. Tools made from carbide or ceramic materials are preferred for their high stiffness, which minimizes deflection.

- Through-tool coolant: Deep bores often require effective chip evacuation, and through-tool coolant systems help flush chips out of the bore while simultaneously reducing heat. This reduces tool wear and ensures a cleaner, more precise bore.

- Reduced cutting speeds: While high speeds may improve productivity, they also increase the risk of tool deflection and overheating in deep bore applications. Reducing the cutting speed, paired with an appropriate feed rate, can help maintain the integrity of both the tool and the workpiece.

Thin-Walled Parts: Minimizing Distortion

When machining thin-walled parts, controlling cutting forces is essential to prevent part distortion. Thin walls tend to vibrate or deform under excessive force, which can compromise dimensional accuracy and surface quality.

To avoid such issues, consider the following approaches:

- Sharp, high-positive rake angle tools: Using tools with sharp edges and high-positive rake angles reduces cutting forces and prevents the workpiece from deforming. These tools are especially useful for minimizing stress on thin-walled components.

- Light cutting passes: Instead of attempting to remove large amounts of material in a single pass, using lighter, more frequent cutting passes can prevent the tool from exerting too much pressure on the part. This method also reduces the risk of chatter and vibration, improving surface quality.

- Toolpath optimization: Careful planning of the cutting tool’s path can significantly reduce stress on thin walls. Engineers should consider climb milling over conventional milling, as it applies cutting forces more directly and steadily, reducing the likelihood of part distortion.

Complex Geometries: Multi-Axis Machining

For parts with intricate geometries—such as curved surfaces, undercuts, and irregular shapes—multi-axis CNC machines provide the necessary flexibility. However, lathe tools used in multi-axis machining must be chosen carefully to account for the changing tool orientations and cutting forces.

Key considerations include:

- Modular tooling systems: These allow for quick tool changes and adaptations without needing to stop the machine. Modular systems enable seamless transitions between roughing and finishing tools, which is especially important for complex geometries that require different tools for various sections.

- Tool wear monitoring: Continuous machining of complex geometries can quickly wear down tools. Implementing real-time tool wear monitoring helps detect wear patterns and adjust cutting parameters to extend tool life without sacrificing part quality.

Data for Complex Machining Strategies

Here’s a quick comparison of machining parameters used for complex parts:

| Complex Part | Preferred Tool Material | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Tooling Strategy |

|---|---|---|---|---|---|

| Deep Bores | Carbide, Ceramic | 50-80 | 0.05-0.12 | 0.5-1 | Through-tool coolant, long-reach tools |

| Thin-Walled Parts | High-positive rake tools | 100-150 | 0.08-0.15 | 0.3-0.6 | Light passes, toolpath optimization |

| Complex Geometries | Carbide, Modular tools | 70-120 | 0.06-0.1 | 0.2-0.5 | Multi-axis machining, tool wear monitoring |

By addressing the challenges of complex part machining, engineers can leverage advanced lathe tool technologies and strategies to achieve optimal results, ensuring high-quality precision and efficiency.

Tool Management and Maintenance: How to Extend Lathe Tool Life in CNC Machining

Proper management and maintenance of lathe tools are critical to extending tool life and maintaining the consistency of CNC machining processes. By implementing effective monitoring systems, maintenance routines, and data-driven strategies, engineers can significantly improve the performance and longevity of their lathe tools.

Tool Monitoring Systems: Real-Time Wear Detection

Modern CNC machines are equipped with advanced tool monitoring systems that provide real-time data on tool wear and performance. These systems use sensors to measure parameters such as cutting force, vibration, and temperature during the machining process. By analyzing these data points, the system can predict when a tool is likely to fail or underperform, allowing for proactive tool replacement before the part quality is compromised.

Tool Monitoring Key Features:

- Vibration monitoring: Unusual vibrations during machining are often the first signs of tool wear or misalignment. Vibration sensors help engineers identify when the cutting tool is no longer stable, enabling them to adjust machining parameters or replace the tool.

- Force measurement: Monitoring the cutting force applied during machining provides insights into tool wear progression. As the tool wears down, it requires more force to maintain cutting performance. By tracking these changes, engineers can predict when the tool is approaching its end of life.

- Automated adjustments: Some advanced systems can automatically adjust cutting parameters (e.g., feed rate, cutting speed) in response to real-time data, extending tool life without human intervention.

Maintenance Strategies: Extending Tool Longevity

Routine maintenance is essential to ensure lathe tools remain in optimal condition. Maintenance strategies should include both preventive measures and reactive responses to tool wear.

Key maintenance practices include:

- Regular inspection and cleaning: Tools should be inspected for wear, chipping, and other damage after every use. Proper cleaning is essential to remove debris and built-up material, which can cause poor cutting performance if not addressed.

- Tool sharpening: For tools made from materials like HSS, regular sharpening helps restore the cutting edge and prolongs the life of the tool. Engineers should follow the manufacturer’s recommended sharpening intervals and techniques.

- Tool replacement schedules: Establishing a predefined tool replacement schedule based on usage and wear data helps prevent tool failure during critical operations. Engineers can rely on wear monitoring systems to determine the optimal replacement intervals.

Data-Driven Tool Life Management

In addition to regular maintenance, data-driven approaches allow engineers to optimize tool life and reduce downtime. By collecting data from previous machining operations, engineers can analyze patterns in tool wear and performance, helping them adjust parameters for future jobs.

Benefits of Data-Driven Tool Management:

- Predictive maintenance: Using historical data, engineers can predict when a tool will wear out, allowing for scheduled replacements that minimize machine downtime.

- Improved cost efficiency: Proactive tool management reduces the frequency of emergency tool replacements, cutting down on unexpected production halts and lowering overall maintenance costs.

- Optimized tool usage: Analyzing wear patterns and tool life data helps engineers select the best tool materials and coatings for specific applications, leading to improved performance and longer tool life.

Proper Tool Storage and Handling

Tool storage is often overlooked in the pursuit of extending tool life, but it plays a critical role in ensuring that tools remain in good condition. Poor storage can lead to premature wear, corrosion, or chipping of delicate cutting edges.

Key Tool Storage Practices:

- Protective cases: Tools should be stored in protective cases or holders that prevent physical contact between tools, reducing the risk of chipping or damage.

- Controlled environment: Tools made from materials prone to corrosion (e.g., HSS) should be stored in a controlled environment where humidity and temperature are monitored.

- Organized storage: Labeling and organizing tools by type, size, and material can help engineers quickly access the right tool for the job, reducing setup times and minimizing the risk of using the wrong tool.

By implementing robust maintenance and management strategies, engineers can extend lathe tool life, improve machining efficiency, and reduce overall production costs.

Enhancing CNC Machining Efficiency

Lathe tools are at the heart of CNC machining efficiency. Proper tool selection, maintenance, and path optimization can significantly reduce cycle times and improve part quality, leading to higher productivity and cost savings.

By mastering the use of lathe tools in complex CNC machining tasks, engineers can not only achieve better results but also push the boundaries of precision engineering.

FAQ

1. How do I select the right lathe tool for a complex CNC machining project?

When selecting a lathe tool for complex machining, consider the material of the workpiece, the tool geometry, and the desired surface finish. Harder materials require more durable tools such as carbide or ceramic. For precision parts, tools with positive rake angles and small nose radii are ideal to minimize cutting forces and improve surface finish.

2. What are the best materials for lathe tools when working with titanium?

For machining titanium, carbide tools with TiAlN or AlTiN coatings are recommended. These coatings offer high heat resistance and minimize tool wear. Titanium is a tough material, and selecting a tool that can withstand high temperatures while maintaining sharpness is critical.

3. How does tool geometry affect surface finish in CNC machining?

Tool geometry, especially the rake angle, nose radius, and clearance angle, directly influences surface finish. A larger nose radius generally results in a smoother surface, while a positive rake angle promotes better chip flow and reduces surface roughness. Proper tool geometry reduces cutting forces, leading to a cleaner finish.

4. What is the best way to extend lathe tool life?

To extend lathe tool life, use tools

with appropriate coatings for the material being machined, monitor tool wear in real-time using sensors, and regularly perform maintenance such as cleaning and sharpening. Optimize cutting parameters to reduce excessive heat and force, and ensure proper tool storage to prevent damage.

5. How can I optimize cutting parameters for difficult-to-machine materials?

For materials like titanium or stainless steel, lower cutting speeds combined with higher feed rates are often more effective. Using a tool with heat-resistant coatings such as TiAlN or DLC helps minimize wear. Adjust cutting depths to balance material removal rates without causing tool overload or excessive wear.

6. What role do tool coatings play in CNC machining efficiency?

Tool coatings such as TiN, TiAlN, and DLC reduce friction between the tool and the workpiece, improve heat resistance, and extend tool life. These coatings allow tools to operate at higher speeds and feed rates without premature wear, making the machining process more efficient.

7. How can I reduce tool wear when machining complex parts?

To reduce tool wear, ensure the tool is correctly aligned and optimize cutting parameters based on the material and geometry of the part. Use high-quality, coated tools and consider implementing a real-time tool monitoring system to adjust parameters as needed. Additionally, use modular tools to reduce the number of tool changes required for complex parts.

Other Articles You Might Enjoy

- Precision Machining with Tool Offsets for CNC Lathe Parts

When it comes to CNC machining, precision is key. Achieving high precision in CNC lathe parts requires a deep understanding of tool offsets and their functions. Let's dive into the…

- Sapphire Machining: Can It Meet the Demands of High-Precision Applications?

Introduction to Sapphire Machining Sapphire machining refers to the precise and intricate process of shaping, cutting, and fine-tuning sapphire materials using specialized techniques. The use of this method has garnered…

- Innovative CNC Machining for the Future of Transportation

Introduction: A Brief Overview of CNC Machining and its Role in Manufacturing CNC machining, also known as Computer Numerical Control machining, is a manufacturing process that uses pre-programmed computer software…

- Bead Blasting: The Secret to Quality CNC Machining(cnc machining tools Mavis)

The world of manufacturing has witnessed revolutionary changes with the advent of Computer Numerical Control (CNC) machining. It is a process used in the manufacturing sector that involves the use…

- Understanding CNC Machining: The Bead Blasting Process(cnc machining tools Valentina)

In the world of manufacturing, precision is paramount. One widely adopted method known for its precision is CNC machining. An integral subcomponent in the broader spectrum of CNC (Computer Numerical…

- The Art of Bead Blasting in CNC Machining(tools for the lathe Rudolf)

Bead blasting, a crucial technique used within the world of Computer Numerical Control (CNC) machining, is a method where small glass beads are propelled at a surface to polish it.…