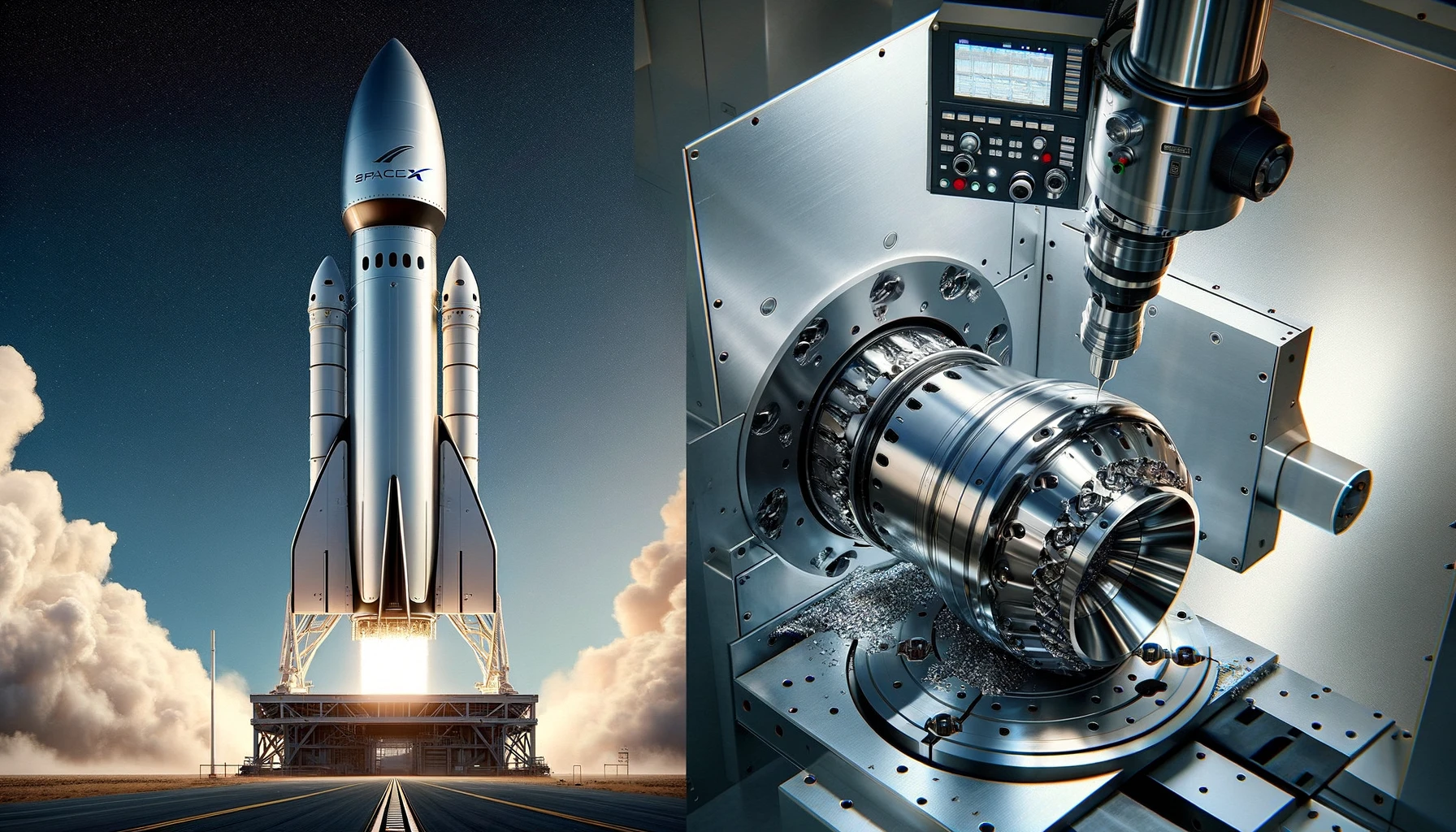

Precision and Accuracy in CNC Machining for SpaceX’s Starship Stainless Steel Parts

CNC machining offers unparalleled precision and accuracy, which is crucial for the manufacturing of SpaceX’s Starship components. The Starship, being an advanced spacecraft, requires parts with extremely tight tolerances to ensure proper assembly and functionality. CNC machines can achieve tolerances as tight as ±0.005 mm, which is essential for aerospace applications.

China Online CNC Machining Services – Want.net

The precision of CNC machining minimizes errors, reduces material waste, and ensures that each part fits perfectly with the others. This precision is achieved through the use of advanced computer software that controls the machining process, allowing for intricate designs and complex geometries to be created with ease. Additionally, CNC machines can replicate the same design multiple times with the same level of accuracy, ensuring consistency in production.

Case Study:

For instance, the production of the Starship’s bulkhead sections, which must withstand high pressure and temperature variations, relies heavily on the precision of CNC machining. Any deviation in the dimensions of these parts could compromise the structural integrity of the spacecraft. Therefore, CNC machining is the preferred method for producing these critical components.

What Challenges Are Faced When CNC Machining Stainless Steel for SpaceX’s Starship?

Stainless steel, though highly durable and resistant to corrosion, presents several challenges when it comes to CNC machining. These challenges include tool wear, heat generation, and maintaining surface finish quality.

Tool Wear and Heat Generation:

Stainless steel is a hard material, and machining it can lead to significant tool wear. The high strength of stainless steel causes more friction, which generates heat. This heat can lead to thermal expansion of the material and the cutting tools, affecting the precision of the parts. Special cutting tools made of carbide or coated with wear-resistant materials are often used to mitigate this issue.

Surface Finish Quality:

Achieving a high-quality surface finish on stainless steel parts is another challenge. The machining process must be carefully controlled to prevent defects such as burrs, rough edges, and scratches. This is critical for the performance and aesthetics of the Starship components.

Data Table: Tool Wear in CNC Machining Stainless Steel

| Tool Material | Wear Rate (mm³/min) | Heat Generation (°C) | Cost per Tool ($) | Durability (Hours) | Surface Finish Quality | Maintenance Frequency (Hours) |

|---|---|---|---|---|---|---|

| HSS | 0.05 | 600 | 20 | 4 | Medium | 2 |

| Carbide | 0.02 | 500 | 50 | 10 | High | 5 |

| Coated Carbide | 0.01 | 450 | 70 | 15 | Very High | 8 |

| Ceramic | 0.015 | 400 | 100 | 20 | High | 10 |

How Does CNC Machining Ensure Cost-Effectiveness in Producing SpaceX Starship Parts?

CNC machining, despite its high initial setup cost, proves to be cost-effective in the long run due to several factors. These include reduced labor costs, material efficiency, and minimal need for rework.

Reduced Labor Costs:

CNC machines are automated and require less manual intervention compared to traditional machining methods. This reduces the labor costs significantly, as one operator can oversee multiple machines. Automation also means that machines can run continuously without breaks, increasing productivity.

Material Efficiency:

CNC machining optimizes the use of raw materials by minimizing waste. The precise cutting reduces the amount of scrap material, which is especially important when working with expensive materials like stainless steel.

Minimal Need for Rework:

The high precision of CNC machining reduces the chances of errors, thus minimizing the need for rework. This not only saves time but also reduces costs associated with additional labor and materials.

Data Table: Cost Analysis of CNC Machining vs. Traditional Machining

| Cost Factor | CNC Machining ($/unit) | Traditional Machining ($/unit) |

|---|---|---|

| Labor Costs | 15 | 40 |

| Material Waste | 5 | 20 |

| Rework Costs | 2 | 10 |

| Tooling Costs | 10 | 5 |

| Total Production Cost | 32 | 75 |

The Role of CNC Machining in Enhancing the Durability of SpaceX’s Starship Parts

Durability is a key requirement for SpaceX’s Starship, given the extreme conditions it must endure during space missions. CNC machining contributes to this durability in several ways.

Material Properties:

CNC machining can enhance the properties of stainless steel parts by allowing for precise control over the manufacturing process. This includes maintaining the integrity of the material’s microstructure and ensuring uniformity in the final product.

Stress Relieving:

CNC machining can also incorporate processes like stress relieving, which reduces the residual stresses within the material. This is crucial for parts that will be subjected to high mechanical loads and temperature fluctuations, ensuring they remain intact and functional over long durations.

Case Study:

An example of this is the production of the Starship’s heat shields, which protect the spacecraft during re-entry into the Earth’s atmosphere. These shields must withstand extreme heat and stress, and CNC machining ensures that each component meets the stringent requirements for durability and performance.

How Does CNC Machining Contribute to the Customization of SpaceX Starship Parts?

Customization is often required for specific parts of the Starship to meet unique design and functional requirements. CNC machining excels in this aspect by allowing for high flexibility and adaptability in the manufacturing process.

Flexible Manufacturing:

CNC machines can be easily reprogrammed to produce different parts without significant downtime. This flexibility is essential for producing customized components that may have unique shapes, sizes, or material requirements. The ability to switch between different projects quickly also enhances the overall production efficiency.

Adaptable Tooling:

The use of adaptable tooling in CNC machining allows for the creation of custom fixtures and jigs that can hold parts in place during the machining process. This ensures precision and accuracy even for custom-designed components.

Example:

For instance, the custom thrusters used in the Starship are produced using CNC machining. These thrusters have specific design requirements to optimize performance in different phases of the mission, and CNC machining allows for precise customization to meet these requirements.

The Impact of CNC Machining on the Overall Quality of SpaceX’s Starship

The quality of the final product is paramount in aerospace manufacturing. CNC machining plays a crucial role in ensuring that SpaceX’s Starship meets the highest quality standards.

Consistency and Repeatability:

CNC machining offers high consistency and repeatability, which means that each part produced is identical to the others. This consistency is critical for ensuring that all parts fit together perfectly and function as intended.

Quality Control:

CNC machining integrates quality control measures throughout the manufacturing process. This includes the use of inspection tools and techniques such as coordinate measuring machines (CMM) to verify the dimensions and tolerances of the parts. Any deviations from the specifications are immediately corrected, ensuring that the final product meets the required standards.

Data Table: Quality Control Measures in CNC Machining

| Quality Control Measure | Description | Impact on Quality | Implementation Cost ($) | Frequency (Hours) |

|---|---|---|---|---|

| Coordinate Measuring Machine (CMM) | Measures part dimensions accurately | Ensures dimensional accuracy | 5000 | 4 |

| In-Process Inspection | Continuous monitoring during machining | Immediate error detection | 3000 | 2 |

| Post-Process Inspection | Final inspection after machining | Verifies overall quality | 2000 | 1 |

| Tool Condition Monitoring | Tracks tool wear and performance | Maintains tool efficiency | 1000 | Continuous |

By addressing these critical aspects, CNC machining ensures that SpaceX’s Starship components are of the highest quality, contributing to the overall success of the mission.

Conclusion

CNC machining provides numerous benefits for the production of SpaceX’s Starship stainless steel parts, from precision and cost-effectiveness to enhanced durability and technological advancements. By overcoming the challenges associated with machining stainless steel and leveraging the latest technologies, CNC machining ensures that each component meets the stringent requirements of aerospace manufacturing. These benefits collectively contribute to the success and reliability of SpaceX’s Starship, paving the way for future space exploration.

Other Articles You Might Enjoy

- Why Is Stainless Steel Preferred for CNC Machining Parts in SpaceX Starship Projects?

Advantages of Stainless Steel in Aerospace Applications Stainless steel offers several advantages in aerospace applications, making it an ideal material for SpaceX’s Starship components. Its high strength-to-weight ratio, excellent corrosion…

- Rapid Prototyping with CNC Machining: High-Quality Stainless Steel Parts

Rapid Prototyping with CNC Machining: High-Quality Stainless Steel Parts In the vast realm of manufacturing, Rapid prototyping and CNC machining are integral strategies that largely contribute to efficient production processes.…

- What Material Properties Need to Be Considered When CNC Machining Stainless Steel Flanges?

The CNC machining of stainless steel flanges requires a profound understanding of the material's properties to ensure high-quality, precision outcomes. This article delves into the critical material properties that impact…

- Fast CNC Machining Services for Stainless Steel Prototyping

CNC Machining and Stainless Steel in Prototyping Computer Numerical Control (CNC) machining is a critical process in the manufacturing sector, particularly for prototyping projects. It's an automated method that uses…

- Precision CNC Machining of Stainless Steel: Innovations and Best Practices in Aerospace Machining

Introduction: Precision CNC Machining and the Use of Stainless Steel Precision Computer Numerical Control (CNC) machining, a vital technology within the manufacturing industry, uses pre-programmed software to guide machinery towards…

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining: The Role of Stainless Steel and Aluminum Computer Numerical Control (CNC) machining is a groundbreaking method in manufacturing that involves precise computer commands to manipulate and control tools…