Understanding Thin-Walled Stainless Steel Parts

Thin-walled stainless steel parts are essential in various industries due to their unique properties. These parts combine strength, durability, and corrosion resistance with a lightweight structure, making them ideal for applications in aerospace, medical devices, and high-precision engineering. However, their thin-walled nature introduces several CNC machining challenges that require specialized approaches to overcome.

China Online CNC Machining Services – Want.net

Why Is Thin-Walled Stainless Steel Difficult to Machine?

Several factors contribute to the difficulty of machining thin-walled stainless steel parts:

- Deflection: Thin walls are less rigid and more prone to bending or deflecting under the pressure of cutting forces. This deflection can lead to inaccuracies in the final dimensions of the part.

- Vibration: The reduced structural rigidity of thin-walled parts makes them more susceptible to vibrations during machining. These vibrations can adversely affect surface finish and tool life.

- Heat Management: Stainless steel has poor thermal conductivity, and thin-walled parts have limited capacity for heat dissipation. Excessive heat buildup can cause thermal expansion, leading to workpiece distortion and reduced dimensional accuracy.

These challenges necessitate specific strategies and tool choices to ensure precision and quality in the final product.

How Does Tool Selection Impact Machining Thin-Walled Stainless Steel?

Tool selection is crucial for effective machining of thin-walled stainless steel parts. Key considerations include:

- Tool Material: High-speed steel (HSS) and carbide tools are preferred for their hardness and wear resistance. Carbide tools, in particular, are effective at maintaining sharp cutting edges under high-stress conditions.

- Tool Geometry: The geometry of the cutting tool, including rake and clearance angles, significantly affects cutting performance. Optimized angles can reduce cutting forces and minimize deflection, leading to better dimensional control.

- Coatings: Applying coatings such as titanium aluminum nitride (TiAlN) to cutting tools can enhance wear resistance, reduce heat generation, and improve overall tool life.

Case Study: Optimizing Tool Selection for Thin-Walled Parts

A manufacturer faced significant challenges with tool wear and part deformation while machining thin-walled stainless steel components. By switching to carbide tools with specialized TiAlN coatings and adjusting tool geometry to optimize rake and clearance angles, they achieved a 25% reduction in tool wear and improved dimensional accuracy. This change led to higher quality parts and increased production efficiency.

The Role of Fixturing and Workholding in Thin-Walled Machining

Effective fixturing and workholding are vital to prevent deflection and vibration during the machining of thin-walled parts:

- Custom Fixtures: Custom-designed fixtures that provide robust support to the thin walls can significantly reduce deflection. These fixtures are tailored to the specific geometry of the workpiece, ensuring stability throughout the machining process.

- Vacuum Clamping: Vacuum clamping systems offer uniform pressure distribution across the workpiece, minimizing the risk of deformation. This method is particularly effective for large, flat, thin-walled parts.

- Damping Materials: Incorporating damping materials into fixtures can absorb vibrations and stabilize the workpiece, enhancing machining accuracy and surface finish.

Example: Custom Fixture for Thin-Walled Part

A CNC shop developed a custom fixture for machining a thin-walled stainless steel part. The fixture incorporated damping materials and used vacuum clamping to secure the workpiece. This setup significantly reduced vibration and deflection, resulting in improved surface finish and dimensional accuracy.

What Cutting Strategies Are Effective for Thin-Walled Stainless Steel?

Employing the right cutting strategies is essential for minimizing deflection and vibration during machining:

- Light Cuts: Taking light cuts with higher feed rates can reduce cutting forces and deflection. This approach allows for more precise material removal without compromising the integrity of the workpiece.

- Climb Milling: Climb milling, where the tool rotates in the same direction as the feed, reduces the tendency for the tool to push the workpiece away. This method helps maintain dimensional accuracy and improves surface finish.

- Step-Down Approach: Gradually removing material in steps rather than a single pass can help control heat buildup and reduce the risk of distortion. This technique is particularly useful for deep cuts in thin-walled parts.

Table: Cutting Strategies and Their Effects on Thin-Walled Stainless Steel Machining

| Strategy | Deflection Reduction | Vibration Control | Heat Management | Surface Finish Improvement |

|---|---|---|---|---|

| Light Cuts | High | Medium | Medium | High |

| Climb Milling | Medium | High | Medium | High |

| Step-Down Approach | High | Medium | High | Medium |

| High Feed Rates | Medium | Low | High | Medium |

| Constant Engagement | High | High | High | High |

How Does Heat Management Affect Machining Thin-Walled Stainless Steel?

Effective heat management is crucial to prevent thermal expansion and distortion in thin-walled stainless steel parts:

- Coolants and Lubricants: Using appropriate coolants and lubricants helps dissipate heat and reduce friction. This is essential to maintain the dimensional stability of the workpiece.

- High-Pressure Coolant Systems: High-pressure coolant systems can effectively remove heat from the cutting zone, preventing thermal damage to the part and tool. This method is particularly beneficial for high-speed machining operations.

- Intermittent Cutting: Allowing time for heat dissipation between cutting passes can reduce thermal buildup. This technique involves strategic pauses in the machining process to manage temperature and maintain part accuracy.

Case Study: Implementing High-Pressure Coolant Systems

A manufacturer experienced significant issues with thermal distortion while machining thin-walled stainless steel parts. By implementing high-pressure coolant systems, they achieved a 30% reduction in thermal expansion-related defects and improved overall part quality. The high-pressure coolant effectively removed heat from the cutting zone, maintaining the integrity of both the tool and the workpiece.

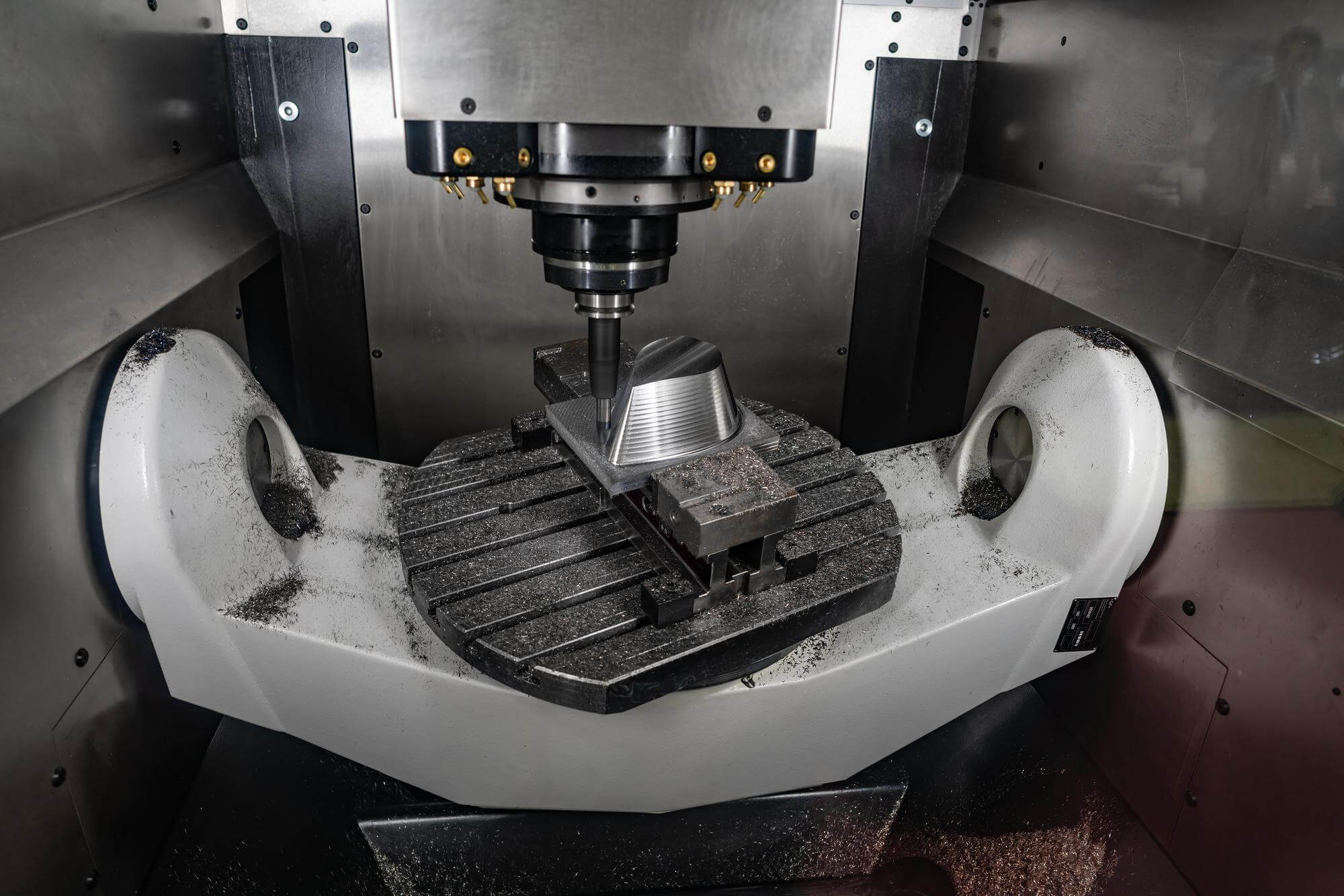

Advanced CNC Technologies for Machining Thin-Walled Stainless Steel

Modern CNC technologies offer solutions to the unique challenges of machining thin-walled stainless steel:

- Adaptive Control: CNC machines with adaptive control can adjust cutting parameters in real-time based on feedback from sensors. This dynamic adjustment optimizes the machining process, enhancing accuracy and efficiency.

- Multi-Axis Machining: Multi-axis CNC machines can approach the workpiece from different angles, reducing the need for multiple setups and minimizing the risk of deflection. This capability allows for more complex geometries to be machined accurately.

- High-Speed Machining: High-speed machining techniques improve surface finish and reduce cutting forces. The reduced forces help prevent deflection and vibration, which are critical when working with thin-walled parts.

Table: Advanced CNC Technologies and Their Benefits

| Technology | Deflection Control | Vibration Reduction | Heat Management | Surface Finish Enhancement |

|---|---|---|---|---|

| Adaptive Control | High | Medium | High | High |

| Multi-Axis Machining | High | High | Medium | High |

| High-Speed Machining | Medium | High | High | High |

| Real-Time Monitoring | High | Medium | High | Medium |

| Predictive Maintenance | Medium | High | Medium | High |

By leveraging these advanced technologies, manufacturers can overcome the inherent challenges of machining thin-walled stainless steel parts. These technologies enable higher precision, improved quality, and greater efficiency in the production process.

Other Articles You Might Enjoy

- What Material Properties Need to Be Considered When CNC Machining Stainless Steel Flanges?

The CNC machining of stainless steel flanges requires a profound understanding of the material's properties to ensure high-quality, precision outcomes. This article delves into the critical material properties that impact…

- Fast CNC Machining Services for Stainless Steel Prototyping

CNC Machining and Stainless Steel in Prototyping Computer Numerical Control (CNC) machining is a critical process in the manufacturing sector, particularly for prototyping projects. It's an automated method that uses…

- Precision CNC Machining of Stainless Steel: Innovations and Best Practices in Aerospace Machining

Introduction: Precision CNC Machining and the Use of Stainless Steel Precision Computer Numerical Control (CNC) machining, a vital technology within the manufacturing industry, uses pre-programmed software to guide machinery towards…

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining: The Role of Stainless Steel and Aluminum Computer Numerical Control (CNC) machining is a groundbreaking method in manufacturing that involves precise computer commands to manipulate and control tools…

- How Does CNC Machining Achieve Precision Tolerances in Stainless Steel Parts?

The Importance of Precision Tolerances in Stainless Steel Parts Precision tolerances are the allowable limits of variation in a physical dimension. In CNC machining, particularly for stainless steel parts, achieving…

- CNC Machining Material Showdown: 304 vs. 316 Stainless Steel

CNC Machining: An Overview And Importance of Material Selection Computer Numerical Control (CNC) machining is a manufacturing process that uses pre-programmed computer software to dictate the movement of factory tools…