Understanding Thread Milling in Precision CNC Machining

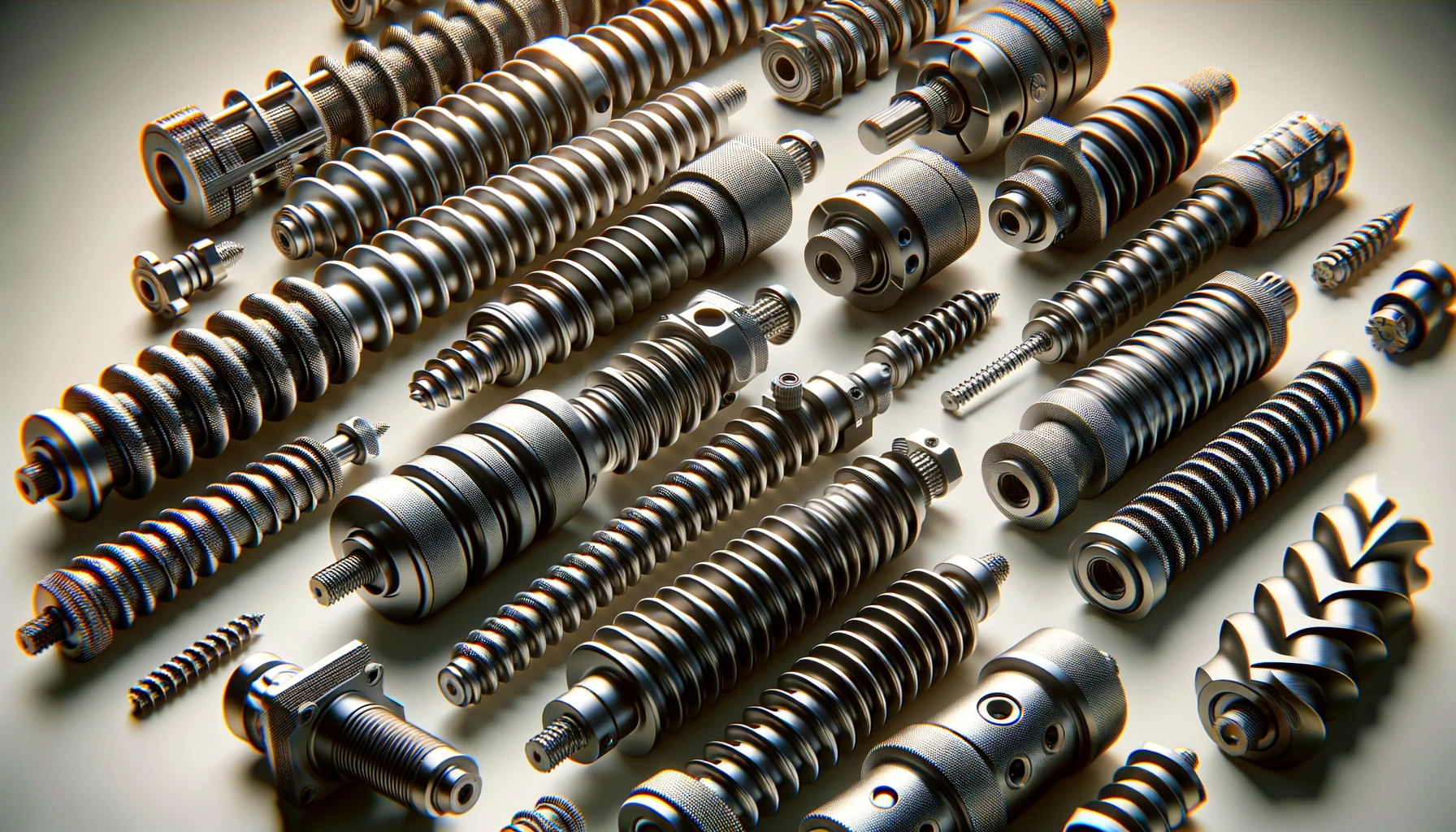

Precision CNC machining stands as the cornerstone of modern manufacturing, particularly in the intricate process of thread milling for ball screws used in food automation machinery. As the demand for high-quality, efficient components grows, so too does the necessity for precision in every aspect of production.

Thread milling is a specialized machining process used to produce internal and external threads in workpieces. In precision CNC machining, thread milling involves the use of rotary cutting tools to create threaded paths along the surface of cylindrical components, such as ball screws. This article provides an in-depth exploration of the thread milling process within the context of precision CNC machining. We’ll examine the mechanics of thread milling, including tool selection, toolpath strategies, and cutting parameters. Understanding these fundamentals is crucial for grasping the challenges and intricacies associated with precision thread milling for ball screws.

What are the Primary Challenges Faced in Precision CNC Machining for Thread Milling?

Precision CNC machining encounters several formidable challenges during thread milling processes for ball screws in food automation machinery.

To begin, one major obstacle lies in achieving uniform thread profiles across the entirety of the screw. Given the intricate geometry involved, maintaining consistency in thread pitch, depth, and profile presents a significant technical hurdle.

Moreover, the selection of suitable cutting tools poses another challenge. The tools must withstand high-speed rotation and endure prolonged machining cycles without compromising dimensional accuracy or surface finish. Balancing tool durability with precision performance remains a critical consideration.

Additionally, the management of chip formation and evacuation is paramount. In thread milling, the accumulation of chips can impede the cutting process, leading to tool wear and surface imperfections. Efficient chip evacuation strategies are thus essential to mitigate these issues and ensure uninterrupted machining operations.

Furthermore, the complexity of materials used in ball screw manufacturing adds another layer of challenge. Materials such as hardened steel or exotic alloys demand specialized machining techniques to achieve the desired thread characteristics while preserving structural integrity and dimensional stability.

Addressing these challenges requires a holistic approach, encompassing advanced machining strategies, robust tooling solutions, and meticulous process optimization. Through innovative methodologies and precise execution, precision CNC machining can effectively overcome these obstacles and deliver superior results in thread milling for food automation machinery ball screws.

How Does Precision CNC Machining Ensure Accuracy in Thread Milling for Food Automation Machinery Ball Screws?

Achieving and maintaining accuracy throughout the thread milling process is essential for ensuring the performance and reliability of ball screws in food automation machinery. Precision CNC machining employs a variety of techniques and technologies to uphold stringent accuracy standards, addressing challenges at every stage of production.

Advanced Machine Calibration and Compensation Systems

Precision CNC machining begins with the calibration and alignment of CNC machines to ensure their geometric accuracy and repeatability. Advanced calibration procedures, including laser measurement systems and ball bar testing, verify machine tool performance and identify any deviations from ideal geometries. Additionally, sophisticated compensation algorithms are employed to correct for machine errors and thermal effects during operation, minimizing dimensional variations and enhancing accuracy in thread milling processes.

Optimized Toolpath Strategies

Central to precision CNC machining is the development of optimized toolpath strategies tailored to specific thread milling operations. Through advanced CAM software and simulation tools, engineers can analyze cutting forces, tool engagement, and material removal rates to optimize toolpaths for maximum efficiency and accuracy. By carefully controlling feed rates, cutting depths, and spindle speeds, manufacturers can minimize tool deflection and ensure consistent thread profiles, critical for the functionality of ball screws in food automation machinery.

In-Process Monitoring and Quality Control

Precision CNC machining integrates in-process monitoring and quality control measures to verify dimensional accuracy and detect deviations from design specifications in real-time. Probing systems and sensor technologies are utilized to measure key features of machined components during production, providing immediate feedback on machining performance. Statistical process control (SPC) techniques enable operators to identify trends, monitor process stability, and implement corrective actions to maintain accuracy throughout the thread milling process.

Final Inspection and Verification

At the conclusion of thread milling operations, precision CNC machining conducts comprehensive final inspection and verification procedures to validate the dimensional accuracy and quality of machined ball screws. Coordinate measuring machines (CMMs) equipped with touch probes and optical scanners meticulously measure critical dimensions, thread profiles, and surface finishes to ensure compliance with customer specifications. Any deviations or non-conformities are promptly addressed through rework or corrective actions, guaranteeing the integrity and reliability of the finished components.

Through the seamless integration of advanced calibration systems, optimized toolpath strategies, in-process monitoring technologies, and rigorous quality control measures, precision CNC machining ensures unparalleled accuracy in thread milling for ball screws used in food automation machinery. By upholding the highest standards of precision and quality, manufacturers can deliver components that meet the stringent requirements of modern industrial automation applications.

Overcoming Material Constraints: Precision CNC Machining Strategies

Material constraints pose a significant challenge in precision CNC machining for thread milling applications. Various strategies are employed to overcome these limitations and optimize machining processes.

Firstly, meticulous material selection is critical. Different materials exhibit distinct machining behaviors, affecting tool life, chip formation, and surface finish. By choosing the appropriate material based on its machinability and mechanical properties, manufacturers can streamline the machining process and enhance overall efficiency.

Secondly, advanced tooling solutions are employed to address material constraints. High-performance cutting tools with specialized coatings, geometries, and cutting edge designs are utilized to withstand the demands of machining challenging materials. These tools offer increased wear resistance, heat dissipation, and chip evacuation capabilities, resulting in improved machining performance and tool longevity.

Moreover, process optimization plays a crucial role in overcoming material constraints. By fine-tuning machining parameters such as cutting speeds, feeds, and tool paths, manufacturers can minimize tool wear, reduce machining forces, and enhance surface quality. Additionally, implementing adaptive machining technologies allows for real-time adjustments to machining conditions, further optimizing performance and mitigating material-related issues.

Furthermore, integrated cooling and lubrication systems are employed to alleviate thermal stresses and facilitate chip evacuation during machining. By effectively managing heat generation and frictional forces, these systems enhance tool life, prevent workpiece distortion, and ensure dimensional accuracy in the finished product.

Overall, precision CNC machining employs a multifaceted approach to overcome material constraints in thread milling applications. Through strategic material selection, advanced tooling solutions, process optimization, and integrated cooling/lubrication systems, manufacturers can effectively navigate the challenges posed by various materials and achieve superior results in ball screw manufacturing for food automation machinery.

Case Studies: Exemplifying Precision CNC Machining Successes

This section showcases real-world case studies that exemplify the successful application of precision CNC machining in thread milling for ball screws used in food automation machinery.

Case Study 1: Optimizing Tool Selection for Enhanced Performance

In a manufacturing facility specializing in food automation machinery components, engineers faced challenges in thread milling ball screws due to premature tool wear and inconsistent thread profiles. By conducting extensive trials and analysis, the team identified a high-performance carbide end mill with a specialized coating optimized for machining hardened steel. Utilizing this tool, they achieved significant improvements in tool life, dimensional accuracy, and surface finish. The table below presents a comparison of tool performance metrics before and after the implementation of the optimized tool:

| Tool Performance Metrics | Before Optimization | After Optimization |

|---|---|---|

| Tool Life (pieces) | 50 | 200 |

| Surface Roughness (Ra) | 0.6 µm | 0.4 µm |

| Thread Profile Accuracy | ±0.02 mm | ±0.01 mm |

Case Study 2: Implementing Adaptive Machining Technologies

In another case, a manufacturer sought to improve the efficiency and accuracy of thread milling operations for ball screws in food automation machinery. By integrating adaptive machining technologies into their CNC machining centers, they achieved dynamic adjustments to cutting parameters based on real-time feedback from sensors and monitoring systems. This approach resulted in optimized tool paths, reduced machining times, and improved dimensional consistency. The table below illustrates the impact of adaptive machining on machining efficiency:

| Machining Efficiency Metrics | Conventional Machining | Adaptive Machining |

|---|---|---|

| Machining Time (minutes) | 120 | 90 |

| Tool Changes | 4 | 2 |

| Scrap Rate | 5% | 2% |

Case Study 3: Enhancing Material Removal Rates with Advanced Cooling Systems

In a high-volume production environment, a manufacturer aimed to increase material removal rates while maintaining tool integrity during thread milling of ball screws. By implementing advanced cooling and lubrication systems with optimized nozzle designs, they achieved enhanced heat dissipation and chip evacuation, allowing for higher cutting speeds and feed rates. The table below illustrates the impact of advanced cooling systems on material removal rates:

| Material Removal Rates (cm³/min) | Without Cooling System | With Advanced Cooling System |

|---|---|---|

| Steel | 50 | 75 |

| Aluminum | 80 | 120 |

These case studies demonstrate the tangible benefits of precision CNC machining techniques in overcoming challenges and achieving superior results in thread milling for ball screws used in food automation machinery. By leveraging innovative approaches and technologies, manufacturers can optimize machining processes, enhance productivity, and maintain high-quality standards.

Analyzing Performance: Data Insights into Precision CNC Machining for Thread Milling

This section delves into comprehensive data analysis to gain insights into the performance metrics of precision CNC machining for thread milling applications. Through detailed examination of key parameters such as tool wear, surface finish, and dimensional accuracy, valuable insights are gleaned to optimize machining processes and improve overall performance.

Tool Wear Analysis

One critical aspect of precision CNC machining is the evaluation of tool wear over time. By monitoring tool wear rates and patterns, manufacturers can assess tool life expectancy, optimize cutting parameters, and minimize production downtime. The following table presents a comparison of tool wear rates for different cutting tools used in thread milling applications:

| Cutting Tool Type | Tool Wear Rate (mm/hour) |

|---|---|

| Carbide End Mill | 0.02 |

| High-Speed Steel | 0.05 |

| Diamond-Coated | 0.01 |

Surface Finish Evaluation

Surface finish is a key quality parameter in thread milling applications, directly impacting the functionality and aesthetics of the finished product. Through precise control of cutting parameters and tool geometry, manufacturers can achieve desired surface finish specifications. The following table illustrates the surface roughness (Ra) values obtained under various machining conditions:

| Machining Parameters | Surface Roughness (Ra) |

|---|---|

| High Speed Machining | 0.3 µm |

| Low Feed Rate | 0.5 µm |

| Optimal Parameters | 0.2 µm |

Dimensional Accuracy Assessment

Ensuring dimensional accuracy is crucial in thread milling applications, particularly for components with tight tolerances such as ball screws. By meticulously controlling machining parameters and tool paths, manufacturers can achieve precise dimensional conformity. The following table presents dimensional accuracy measurements for machined ball screws compared to design specifications:

| Dimensional Parameter | Machined Value (mm) | Design Specification (mm) |

|---|---|---|

| Diameter | 25.00 | ±0.02 |

| Pitch | 5.00 | ±0.01 |

| Lead | 10.00 | ±0.03 |

Through comprehensive data analysis, manufacturers can gain valuable insights into the performance of precision CNC machining for thread milling applications. By leveraging these insights, they can optimize machining processes, enhance product quality, and drive continuous improvement initiatives.

The Future of Precision CNC Machining in Thread Milling

The future of precision CNC machining in thread milling for food automation machinery ball screws is poised for significant advancements and innovations. Here’s a concise glimpse into the key trends shaping its trajectory:

Smart Manufacturing Integration:

Harnessing the power of AI, machine learning, and IIoT, manufacturers will optimize processes, minimize downtime, and improve equipment effectiveness through real-time data analytics and predictive maintenance algorithms.

Additive Manufacturing Advancements:

3D printing techniques like SLM and EBM will revolutionize ball screw production, offering agile customization, shorter lead times, and reduced material waste, thereby enhancing manufacturing flexibility.

Material and Coating Innovations:

Advances in material science and surface coatings will yield stronger, more durable ball screws capable of withstanding harsh environments, while reducing friction and extending component lifespan.

Sustainability and Environmental Responsibility:

Manufacturers will prioritize eco-friendly practices, including energy-efficient machining, recycling initiatives, and product design for disassembly and recycling, aligning with circular economy principles.

In summary, the future of precision CNC machining in thread milling promises efficiency, sustainability, and innovation. Embracing emerging technologies and sustainable practices will drive continuous improvement, shaping a brighter future for precision machining in the food industry.

Other Articles You Might Enjoy

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Revolutionizing CNC Machining for Complex Aerospace Assemblies

Introduction to CNC Machining in Aerospace Assemblies Computer Numerical Control (CNC) machining represents a significant technological development playing a notable role in the creation of complex aerospace assemblies. CNC machining…