What is 4140 Steel? What are Its Key Characteristics?

When I first encountered 4140 steel in CNC machining projects, I was struck by its versatility and dependability. It’s a chromium-molybdenum alloy steel known for its unique balance of strength, toughness, and wear resistance. These properties make it an exceptional choice for applications requiring high performance. Custom machining with 4140 steel allows for the precise shaping and finishing of parts that can withstand harsh environments and demanding conditions. As we produced CNC machined parts for heavy-duty machinery, I noticed that the material’s durability and resistance to fatigue made it ideal for parts that would experience constant stress and wear. This ensured that the components maintained their integrity and performance over extended periods, even in the most challenging applications.

1.1 Chemical Composition and Mechanical Properties of 4140 Steel

The distinct mechanical properties of 4140 steel stem from its carefully engineered chemical composition:

| Element | Typical Content (%) |

|---|---|

| Carbon (C) | 0.38–0.43 |

| Chromium (Cr) | 0.80–1.10 |

| Molybdenum (Mo) | 0.15–0.25 |

| Manganese (Mn) | 0.75–1.00 |

| Silicon (Si) | 0.15–0.35 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.040 |

These elements contribute to the steel’s impressive strength, wear resistance, and ability to undergo heat treatment.

Mechanical properties further highlight why 4140 steel is favored in demanding environments:

| Property | Typical Value |

|---|---|

| Tensile Strength | 655 MPa (min) |

| Yield Strength | 415 MPa (min) |

| Elongation (%) | 20 (min) |

| Brinell Hardness (HBW) | 197–255 |

| Impact Energy (J) | 35 (min, longitudinal) |

1.2 Comparison with Other Common Steels

To better understand why 4140 steel stands out, let’s compare it with other popular steels used in CNC machining:

| Steel Type | Key Characteristics | Applications |

|---|---|---|

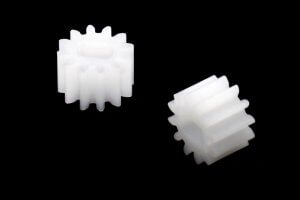

| 1045 Steel | Moderate strength, good machinability | Gears, bolts, and shafts |

| 4340 Steel | Excellent fatigue resistance, higher toughness | Heavy-duty axles, aerospace parts |

| 4140 Steel | Balanced strength, toughness, and wear resistance | Tooling, molds, automotive parts |

1.3 Why 4140 Steel Stands Out

What makes 4140 steel so appealing is its versatility. It can be heat-treated to enhance specific properties, such as hardness or toughness, while remaining relatively easy to machine in its annealed state. Its unique composition and mechanical properties allow it to handle high-stress environments without sacrificing durability.

Why is 4140 Steel Ideal for CNC Machining?

Over the years, I’ve worked with a variety of materials in CNC machining, but 4140 steel consistently delivers exceptional results. It strikes the perfect balance between machinability and performance.

2.1 Advantages of CNC Machining 4140 Steel

- High Dimensional Stability: 4140 steel maintains its shape during machining, even under high temperatures. This makes it ideal for precision parts.

- Good Machinability: Despite its strength, 4140 steel is relatively easy to machine in its annealed state, allowing for efficient manufacturing.

- Versatility: It can be heat-treated to meet specific project requirements, such as increased hardness or strength.

- Wear Resistance: This steel’s durability ensures a long service life for components in high-stress environments.

2.2 Recommended Machining Parameters and Tooling

To get the most out of CNC machining 4140 steel, it’s critical to use the right cutting parameters and tools:

| Machining Process | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

| Turning (annealed) | 50–80 | 0.2–0.3 | 2–4 |

| Milling (annealed) | 40–70 | 0.15–0.25 | 2–4 |

| Drilling | 30–50 | 0.1–0.2 | 2–3 |

Tooling Recommendations:

- Carbide Tools: Essential for machining hardened 4140 steel.

- Coolant Use: High-quality coolant is necessary to control heat and extend tool life.

- Coated Tools: TiN or TiAlN coatings improve durability and reduce friction.

How to Heat Treat 4140 Steel to Meet Specific Needs?

Heat treatment is where 4140 steel truly shines. By modifying its internal structure, we can tailor its mechanical properties to meet the needs of specific applications.

3.1 Quenching and Tempering

One of the most common processes for 4140 steel is quenching and tempering:

- Quenching: Heat the steel to 1500°F–1600°F, then rapidly cool it in oil or water. This increases hardness.

- Tempering: Reheat the material to a lower temperature (400°F–700°F), then cool slowly to reduce brittleness and improve toughness.

3.2 Hardness and Toughness Changes After Heat Treatment

| Heat Treatment | Hardness (HRC) | Toughness |

|---|---|---|

| Annealed | 10–20 | High |

| Quenched and Tempered | 28–60 | Moderate to High |

| Normalized | 18–25 | Balanced |

Heat treatment allows you to optimize the steel for specific applications. For example, in my projects, I’ve used quenched and tempered 4140 steel for wear-resistant parts, while normalized steel is ideal for general-purpose components.

Applications of 4140 Steel in Various Industries

4140 steel’s combination of strength, toughness, and machinability makes it indispensable across many industries. From automotive components to energy sector tools, its applications are as varied as they are demanding.

4.1 Typical Parts in Different Industries

| Industry | Common Components | Why Use 4140 Steel? |

|---|---|---|

| Automotive | Gears, axles, crankshafts | High fatigue resistance and wear resistance |

| Aerospace | Landing gear parts, structural fasteners | Lightweight strength and toughness |

| Industrial Tools | Dies, molds, tool holders | Hardness and ability to withstand repetitive stress |

| Energy | Drill collars, valve bodies, couplings | Excellent durability in high-pressure environments |

| Construction | Hydraulic machinery parts, anchor bolts | High tensile strength and impact resistance |

4.2 Design Considerations for Specific Applications

- High-Stress Components

Parts like gears and crankshafts are subjected to cyclic stresses. In my experience, 4140 steel’s ability to be heat-treated ensures these components maintain durability under repeated loads. - Wear-Resistant Applications

For tools and dies, surface hardness is critical. Using heat-treated 4140 steel with a hardness of 40-50 HRC can significantly extend tool life. - Precision Engineering

4140 steel’s dimensional stability makes it a great choice for aerospace fasteners and other high-precision parts. - Dynamic Applications

In parts like couplings and shafts, 4140 steel offers an excellent balance of ductility and toughness, minimizing the risk of sudden failure.

Challenges and Solutions in CNC Machining 4140 Steel

As reliable as 4140 steel is, machining it isn’t without its challenges. Over the years, I’ve faced many of these firsthand, but with the right strategies, these hurdles can be overcome.

5.1 Common Challenges

- Tool Wear

Hardened 4140 steel can quickly wear down cutting tools. Without proper tooling, productivity can suffer. - Heat Generation

Machining at high speeds generates significant heat, which can affect both tool life and part accuracy. - Dimensional Accuracy

Post-machining, heat-treated 4140 steel can distort, especially in components requiring tight tolerances.

5.2 Solutions to Improve Machining Efficiency

| Challenge | Solution |

|---|---|

| Tool Wear | Use carbide or coated tools (e.g., TiAlN). |

| Heat Generation | Employ high-quality coolants and lower speeds. |

| Dimensional Distortion | Rough machine before heat treatment, finish after. |

Additionally, optimizing feed rates and depth of cut can significantly improve results. I’ve also found that regular tool inspections and replacements reduce downtime.

How to Choose Reliable 4140 Steel Suppliers and CNC Machining Services?

Finding the right supplier or machining partner is critical to ensuring project success. Here’s what I’ve learned when sourcing 4140 steel and CNC services.

6.1 Material Selection and Quality Standards

Ensure the supplier provides certified materials that meet industry standards. Look for:

| Standard | Description |

|---|---|

| ASTM A29/A29M | Standard specification for alloy steel bars |

| SAE 4140 | American specification for 4140 steel |

| DIN 1.7225 | European specification |

Always request material certifications and confirm the chemical composition matches your project requirements.

6.2 Key Considerations for Choosing a CNC Machining Service

- Expertise with 4140 Steel

CNC machinists experienced with 4140 steel will better handle its unique challenges, from tooling to post-processing. - Tooling Capabilities

Ensure the service provider uses carbide tools and can adjust machining parameters for different states of 4140 steel. - Precision and Tolerances

Check the provider’s ability to achieve tight tolerances, especially for heat-treated components. - Turnaround Time

Look for services that balance speed with quality. It’s essential for industries like automotive and aerospace where time-to-market is critical.

Conclusion

4140 steel is a remarkable material for CNC machining, balancing strength, toughness, and machinability. Whether you’re designing high-stress automotive parts or precision aerospace components, 4140 steel is a dependable choice. With the right machining techniques and suppliers, it’s possible to unlock the full potential of this versatile alloy.

FAQ

- Is 4140 steel suitable for high-load components?

Yes, its strength and toughness make it ideal for gears, shafts, and other high-stress parts. - Can 4140 steel be machined easily?

In its annealed state, 4140 steel is easy to machine. Hardened steel requires specialized tooling. - What are the typical applications of 4140 steel?

Automotive gears, aerospace fasteners, oil and gas tools, and industrial molds are common uses. - What is the best heat treatment for 4140 steel?

Quenching and tempering provide an excellent balance of hardness and toughness. - How does 4140 steel compare to 4340 steel?

4140 is less tough than 4340 but offers better machinability and cost-effectiveness for many applications. - What tools are best for machining 4140 steel?

Carbide tools with TiAlN coating are preferred for hardened 4140 steel. - Can 4140 steel be welded?

Yes, but preheating and post-weld heat treatment are necessary to avoid cracking. - What industries use 4140 steel the most?

Automotive, aerospace, energy, and industrial tooling are the primary sectors. - How do I select the right supplier for 4140 steel?

Look for certifications, material standards, and a proven track record. - Does machining 4140 steel generate a lot of heat?

Yes, which is why proper coolants and machining strategies are essential. - Is 4140 steel corrosion-resistant?

It has some resistance due to chromium but usually requires coatings or treatments for high-corrosion environments. - What’s the maximum hardness of 4140 steel?

After quenching and tempering, it can reach up to 60 HRC. - Can CNC machining achieve tight tolerances on 4140 steel?

Yes, with proper setup and machining strategies, precise tolerances are achievable. - What are the cost implications of machining 4140 steel?

Tooling and heat treatment can add to the cost, but the durability of components justifies the expense. - Is 4140 steel sustainable for long-term use?

Its durability and wear resistance make it an excellent choice for long-lasting components.

Other Articles You Might Enjoy

- Understanding AISI 4140: The Ultimate Guide for CNC Machinists

Introduction to AISI 4140: A Versatile Alloy Steel When it comes to CNC machining, material selection is crucial, and AISI 4140 stands out as one of the most versatile and…

- Comprehensive Guide to CNC Machining: Carbon Steel vs Stainless Steel

Choosing the right material for CNC machining is a crucial decision for any manufacturer or engineer. Two of the most commonly used materials in various industries are carbon steel and…

- Low carbon steel in CNC machining offers affordable and reliable solutions

Why Low Carbon Steel Is Ideal for CNC Machining Low carbon steel, often referred to as mild steel, is a versatile material favored across industries for its balance between affordability…

- Titanium vs Steel Choosing the Right Material for CNC Machining

A Brief Introduction to the Importance of Titanium and Steel in Manufacturing In the modern world, manufacturing has become the backbone of economic development, driving industries, innovation, and infrastructure. At…

- Conquering High-Strength and Ultra-High-Strength Steel in CNC Machining Precision and Techniques Revealed

High-strength and ultra-high-strength steels (HSS and UHSS) are engineering marvels, known for their exceptional combination of strength and toughness. These steels are crucial in industries such as aerospace, automotive, and…

- Mastering Bead Blasting in CNC Machining(heat treatment of steel Brandon)

CNC (Computer Numeric Control) machining is a powerful technology that has revolutionized modern fabrication methods. From small and intricate parts to large volumes, CNC machines can handle a variety of…

- Streamlining CNC Machining for Lightweight Metals( alloy steel Veromca)

In recent years, computer numerical control (CNC) machining has emerged as a highly efficient method for processing various types of materials—including lightweight metals. Efficient in operation and precise in execution,…