Why Hard Anodized Aluminum and CNC Machining Are Your Best Choice

If you’re a customer seeking high-performance, durable, and precision-engineered parts, this article is tailored to your needs. Hard anodized aluminum combined with CNC machining offers a solution for producing parts that withstand extreme environments while maintaining exceptional precision. Whether you’re involved in aerospace, automotive, electronics, or medical devices, this article will demonstrate how this powerful combination can improve part durability, reduce maintenance, and enhance overall performance. By the end of this article, you’ll understand why hard anodized aluminum is ideal for CNC machined parts and how it can optimize your projects by extending part life and lowering long-term costs.

What is Hard Anodized Aluminum?

Hard anodized aluminum is a specially treated aluminum that undergoes an electrochemical process known as hard anodizing. This process forms a thick and durable oxide layer on the aluminum surface, making it much harder, more resistant to wear, and highly corrosion-resistant.

The key advantages of hard anodized aluminum over untreated or standard anodized aluminum include:

- Increased surface hardness: Hard anodized layers are typically 25-150 microns thick, providing a ceramic-like hardness.

- Corrosion resistance: The process makes aluminum parts more resistant to environmental factors like moisture and chemicals.

- Durability: Parts are better equipped to handle physical wear and tear, increasing the lifespan of the components.

This process is highly valuable in industries where parts are exposed to harsh environments and require long-lasting performance. Hard anodizing is commonly used in industries like aerospace, automotive, defense, and electronics, where both the durability and lightweight nature of aluminum are advantageous.

| Hard Anodized Aluminum Properties | Description |

|---|---|

| Thickness of Oxide Layer | 25-150 microns |

| Surface Hardness | Up to 60-70 HRC (comparable to ceramics) |

| Corrosion Resistance | Excellent in harsh environments |

| Weight Increase After Anodizing | Minimal (due to thin oxide layer) |

| Typical Applications | Aerospace, Automotive, Electronics |

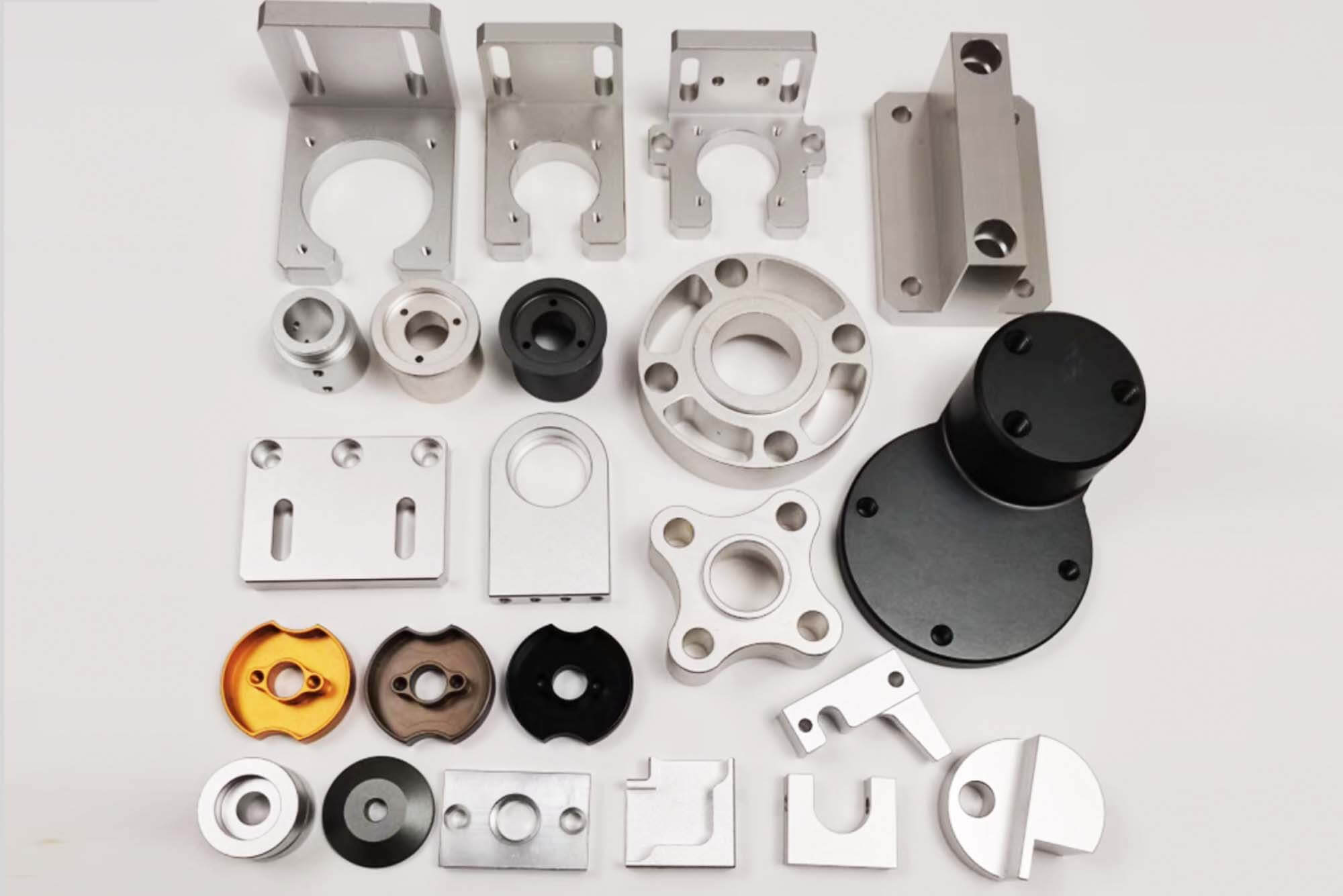

How CNC Machining and Hard Anodized Aluminum Work Together

CNC machining and hard anodized aluminum form a powerful combination for producing high-performance parts. CNC machining allows for the precision cutting and shaping of aluminum components to exact tolerances, while the hard anodizing process enhances these parts with increased durability and resistance to wear.

In my experience, CNC machining plays a crucial role in shaping aluminum parts with extreme accuracy. It ensures that the parts are made to precise specifications, which is especially important before the hard anodizing process. Once the parts are anodized, they benefit from the enhanced surface properties without compromising the part’s precision.

Hard anodized aluminum is frequently used in CNC machining to create components for industries that require both precision and durability. Here are some examples:

- Aerospace: Components like brackets, mounts, and frames that need to withstand high levels of stress.

- Automotive: Lightweight but durable parts like pistons, suspension components, and heat sinks.

- Electronics: Housings and heat sinks for devices requiring thermal management and corrosion resistance.

| Industry | CNC Machined Hard Anodized Parts Example | Benefits |

|---|---|---|

| Aerospace | Structural components, brackets | High strength-to-weight ratio, corrosion resistance |

| Automotive | Pistons, suspension components | Lightweight, wear resistance |

| Electronics | Heat sinks, device housings | Thermal management, durability |

| Medical Devices | Surgical instruments, enclosures | Sterilizable, corrosion resistant |

Key Applications of Hard Anodized Aluminum

Hard anodized aluminum is a material that excels in many high-demand applications due to its combined properties of hardness, corrosion resistance, and light weight. Let’s break down its application in various industries:

- Aerospace:

In aerospace, weight and durability are crucial. Hard anodized aluminum is used in structural components where lightweight materials that can handle high stress are needed. The hard oxide layer provides durability without adding significant weight. - Automotive:

In automotive applications, hard anodized aluminum is commonly used in engine components like pistons, as well as heat exchangers. It provides wear resistance in parts exposed to high temperatures and friction, increasing part longevity and reducing maintenance costs. - Electronics:

Aluminum’s excellent thermal conductivity makes it a top choice for heat sinks in electronic devices. Hard anodized aluminum can withstand high temperatures without corroding, making it perfect for electronic housings and heat-dissipating parts. - Medical Devices:

Medical applications require materials that are both durable and sterilizable. Hard anodized aluminum fits perfectly here, with its non-reactive surface and ability to be repeatedly sterilized without degrading.

| Application Field | Hard Anodized Aluminum Use Case | Key Advantages |

|---|---|---|

| Aerospace | Brackets, frames, mounts | Lightweight, durable |

| Automotive | Pistons, suspension components | Wear resistance, high temperature |

| Electronics | Heat sinks, housings | Corrosion resistance, thermal management |

| Medical Devices | Surgical tools, sterilizable parts | Non-reactive, sterilizable |

Hard Anodized vs. Standard Anodized Aluminum: What’s the Difference

When comparing hard anodized aluminum to standard anodized aluminum, several key differences stand out, primarily in terms of thickness, hardness, and resistance properties. These differences make hard anodized aluminum more suitable for high-stress and high-wear applications, while standard anodized aluminum is often used for lighter or decorative purposes.

- Oxide Layer Thickness:

Hard anodized aluminum has a much thicker oxide layer, typically ranging from 25 to 150 microns, while standard anodized aluminum usually has a layer of 5 to 25 microns. The thicker oxide layer in hard anodizing gives parts a significant boost in wear and corrosion resistance, making them more durable in demanding environments. - Surface Hardness:

The surface hardness of hard anodized aluminum is comparable to that of ceramics, with a hardness of up to 60-70 HRC. Standard anodized aluminum, on the other hand, has a hardness of about 30-40 HRC. This makes hard anodized parts far more resistant to physical damage, abrasion, and scratching. - Corrosion Resistance:

Hard anodized aluminum is well-suited for use in harsh environments, such as marine or industrial settings, where parts are exposed to moisture, chemicals, or extreme temperatures. The thicker oxide layer provides exceptional protection, whereas standard anodized aluminum, while offering some corrosion resistance, is better suited for less demanding environments. - Wear Resistance:

Hard anodized aluminum is ideal for mechanical and moving parts due to its superior wear resistance. The thick, hard oxide layer can endure repeated contact, making it useful for components that are exposed to friction or abrasive conditions. In contrast, standard anodized aluminum, with its thinner oxide layer, is more appropriate for applications where wear resistance is less of a concern. - Applications:

Hard anodized aluminum is often found in aerospace, automotive, and military applications where durability, strength, and resistance are key. Standard anodized aluminum, however, is typically used for more decorative purposes, such as in consumer electronics or architecture, where appearance and a moderate level of corrosion resistance are sufficient.

| Comparison Factor | Hard Anodized Aluminum | Standard Anodized Aluminum |

|---|---|---|

| Oxide Layer Thickness | 25-150 microns | 5-25 microns |

| Surface Hardness | 60-70 HRC (comparable to ceramics) | 30-40 HRC (moderate hardness) |

| Corrosion Resistance | Excellent, suitable for harsh environments | Good, but less resistant in harsh environments |

| Wear Resistance | High, ideal for mechanical applications | Moderate, better for decorative uses |

| Applications | Aerospace, automotive, medical | Consumer products, architectural finishes |

In my own experience, hard anodizing has been the go-to solution for components that will face tough physical demands. In CNC machining, I’ve found that this process significantly enhances the longevity and robustness of parts, especially in applications like automotive engine components and aerospace parts that require both precision and resilience.

Cost Optimization Strategies for CNC Machined Hard Anodized Aluminum Parts

Producing CNC machined hard anodized aluminum parts involves both precision and cost considerations. While hard anodizing adds to the cost of production, several strategies can be employed to optimize expenses without sacrificing quality.

- Optimized CNC Programming:

One way to reduce costs is by optimizing the CNC programming. Efficient programming minimizes unnecessary tool movements, reduces machining time, and lowers the likelihood of errors that can result in scrapped parts. Simulation software can be used to test tool paths and identify potential problems before production begins, further saving time and resources. - Batch Processing:

Another cost-saving approach is batch processing. Grouping parts for both CNC machining and anodizing allows for more efficient use of machine time and reduces overhead per part. This is particularly effective during the anodizing process, as multiple parts can be treated simultaneously in the same bath. - Tool Selection:

Selecting the right cutting tools for CNC machining aluminum is crucial. Using high-speed cutting tools and optimized tool coatings can reduce tool wear and increase machining speed, lowering both tool replacement costs and production times. - Material Utilization:

Efficient use of material is another important cost factor. Reducing material waste through optimized nesting (arranging parts to minimize waste on the raw material sheet) and making full use of each piece of aluminum can greatly reduce material costs, which is particularly important when using high-quality, hard anodized aluminum. - Supplier Collaboration:

Working closely with your CNC machining supplier can also lead to cost savings. A supplier with experience in both CNC machining and hard anodizing can help identify ways to streamline the production process, reduce material waste, and improve efficiency. Additionally, choosing a supplier who can handle both machining and anodizing under one roof can eliminate the need for transporting parts between multiple vendors, saving time and logistical costs. - Process Integration:

Integrating the CNC machining and anodizing processes can cut down on production delays and help maintain quality control. When both processes are managed by the same supplier, coordination improves, reducing the likelihood of miscommunication or errors that might increase costs or lead to defects.

| Cost Optimization Strategy | Benefit |

|---|---|

| Optimized CNC Programming | Reduces machining time, lowers scrap rates |

| Batch Processing | Lowers per-part costs |

| Tool Selection | Increases tool life, reduces replacement frequency |

| Material Utilization | Minimizes waste, reduces material costs |

| Supplier Collaboration | Streamlines production, reduces transportation costs |

| Process Integration | Improves efficiency, lowers risk of defects |

By employing these strategies, you can ensure that the production of hard anodized aluminum parts is both cost-effective and high-quality, making this material choice an even more attractive option for industries that prioritize durability and precision.

Conclusion

Hard anodized aluminum offers a robust and versatile solution for industries requiring high-performance components. By combining the precision of CNC machining with the durability and wear resistance of hard anodizing, manufacturers can produce parts that withstand challenging environments and extend product life.

Whether you are in the aerospace, automotive, or electronics industry, hard anodized aluminum can significantly enhance the quality and longevity of your parts. The ability to maintain lightweight properties while adding a ceramic-like hardness makes it an ideal material for components that require both precision and durability.

From optimizing CNC programming to batch processing and supplier collaboration, cost-effective strategies are available to maximize the benefits of using hard anodized aluminum. This makes it not only a high-performance material but also a cost-effective one for long-term projects.

In summary, hard anodized aluminum is an excellent choice for CNC machined parts that need to excel in durability, precision, and resistance to wear. By understanding how to leverage this material through the right machining processes, you can achieve exceptional results for your custom components.

FAQ

- What is the difference between hard anodized and standard anodized aluminum?

Hard anodized aluminum has a much thicker and harder oxide layer (25-150 microns) compared to standard anodized aluminum (5-25 microns). This makes hard anodized aluminum more resistant to wear, corrosion, and physical damage, while standard anodizing is typically used for decorative or lightweight applications. - How does CNC machining improve the performance of hard anodized aluminum parts?

CNC machining ensures that aluminum parts are precisely shaped to exact tolerances, providing a foundation for the hard anodizing process. The combination allows for precision components that also benefit from increased hardness, corrosion resistance, and durability after anodizing. - What industries benefit most from hard anodized aluminum?

Hard anodized aluminum is widely used in industries such as aerospace, automotive, electronics, and medical devices. These industries require materials that are both lightweight and durable, capable of withstanding harsh environments or high levels of wear and tear. - How does the thickness of the oxide layer affect the durability of hard anodized aluminum?

A thicker oxide layer increases surface hardness, making the part more resistant to abrasion and wear. The thickness also improves corrosion resistance, making hard anodized aluminum suitable for use in challenging environments like marine or industrial settings. - What are the typical applications for hard anodized aluminum in CNC machining?

Hard anodized aluminum is commonly used in aerospace structural components, automotive pistons and suspension parts, heat sinks for electronics, and surgical instruments in the medical field. - How do I know if hard anodized aluminum is the right choice for my project?

If your project requires parts that need to withstand high levels of wear, corrosion, or harsh environments, hard anodized aluminum is an excellent choice. Its lightweight properties, combined with increased surface hardness, make it ideal for precision-engineered components. - What surface finishes can be applied to hard anodized aluminum parts?

After hard anodizing, the aluminum part can receive further surface treatments such as polishing, brushing, or laser engraving. These finishes enhance the part’s appearance or add additional functionality, such as improved grip or branding. - Does hard anodized aluminum increase the weight of CNC machined parts?

No, hard anodizing adds only a thin oxide layer, so the weight increase is minimal. This allows for improved durability without significantly affecting the part’s weight, maintaining the lightweight advantages of aluminum. - How does hard anodizing affect the thermal properties of aluminum?

Hard anodizing adds a ceramic-like layer to the surface, which can slightly reduce the thermal conductivity of aluminum. However, the thermal management properties of aluminum are still sufficient for most applications, especially in electronics where heat dissipation is critical. - What are the limitations of using hard anodized aluminum in CNC machining?

One limitation of hard anodized aluminum is that the thick oxide layer can be brittle and prone to cracking under extreme stress. Additionally, the anodizing process adds time and cost to production, so it may not be necessary for every application.

Other Articles You Might Enjoy

- Unraveling the World of CNC Machined Plastic Parts(CNC machined plastic parts Mabel)

Modern innovations have taken traditional manufacturing methods to new heights. One such innovation that stands out is Computer Numerical Control (CNC) machining, a process used extensively in various industries from…

- CNC Machined Plastic Parts: An In-depth Overview(CNC machined plastic parts Norman)

Computer Numeric Control (CNC) machining is an advanced manufacturing process where pre-programmed software dictates the movement of factory machinery and tools. These applications can carry out complicated manufacturing tasks with…

- Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the…

- The Role of Surface Finishing in CNC Machined Parts: Anodizing Aluminum vs. Electroplating Steel

The Role of Surface Finishing in CNC Machined Parts: Introduction and Background Knowledge Surface finishing, integral to the manufacturing process, is a group of industrial procedures employed on the outer…

- Anodized vs. Non-Anodized Aluminum: Which Is Better for CNC Projects?

An Introduction to Anodized and Non-Anodized Aluminum in CNC Projects In the realm of Computer Numerical Control or CNC projects, aluminum assets serve a pivotal role. Two classifications include anodized…

- Weighing the Costs Titanium vs Aluminum in CNC Machined Parts

When it comes to CNC machining, choosing the right material is a crucial decision that can significantly impact the cost, performance, and longevity of the final product. Two of the…