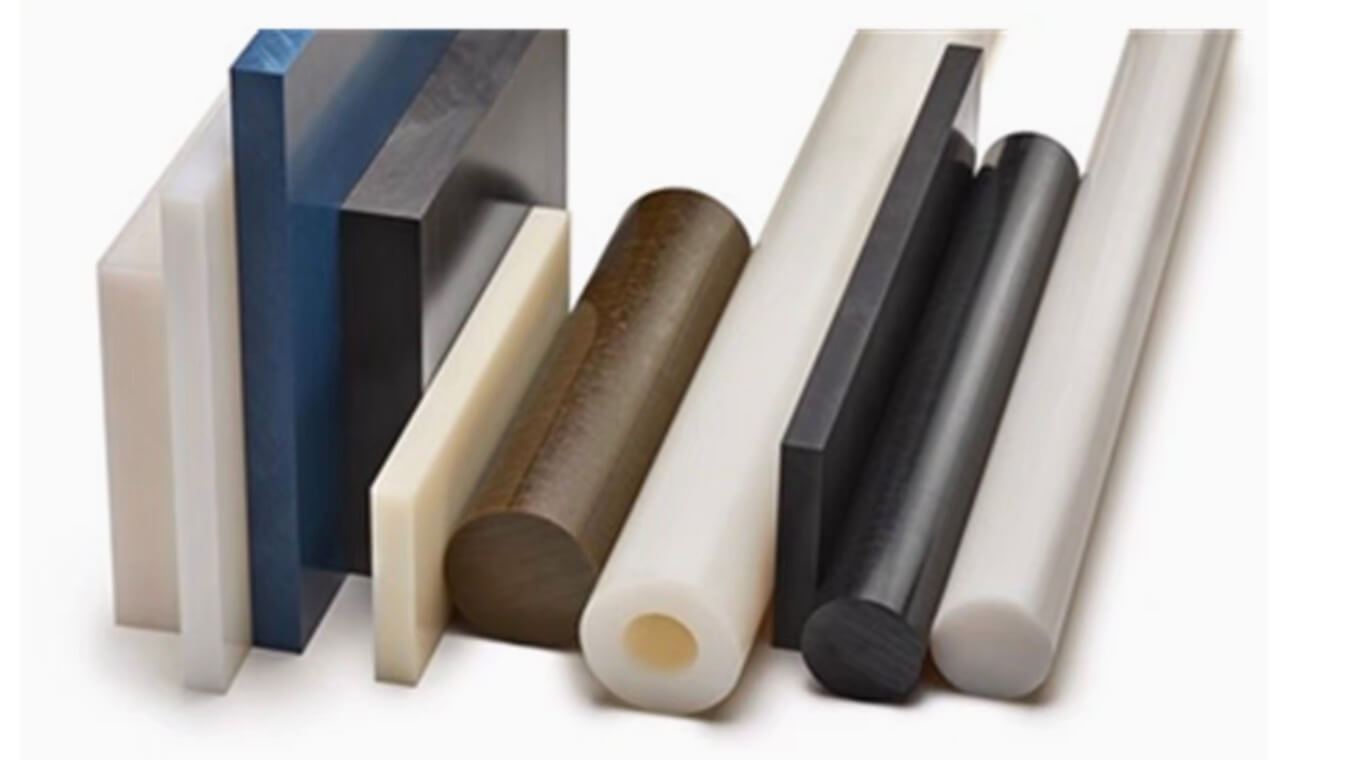

Working with CNC machining over the years has revealed the importance of choosing the right material for precision parts. Delrin, a type of acetal homopolymer, quickly became a favorite for producing components that need to withstand mechanical stress, maintain dimensional stability, and resist wear over time. With its unique combination of strength, durability, and machinability, Delrin stands out as an excellent material for custom CNC machining. This article explores why Delrin is such an ideal choice, based on firsthand experience in various CNC applications.

Why Delrin Is the Ideal Material for Custom CNC Machined Parts

When selecting materials for custom CNC machined parts, Delrin consistently proves its value. Its mechanical strength, chemical resistance, and ease of machining make it a standout option.

Key Properties of Delrin

- High Strength and Rigidity: Delrin offers exceptional strength, allowing it to handle heavy loads without deformation, even in demanding applications.

- Low Friction and Wear Resistance: This material’s low friction coefficient is perfect for parts like gears and bearings, where wear resistance is critical.

- Dimensional Stability: Delrin maintains its dimensions even in fluctuating temperatures and humidity, which is essential for precision parts.

- Chemical Resistance: Its resistance to solvents, oils, and fuels makes Delrin versatile across many industries.

These properties make Delrin ideal for CNC machined parts that need durability and long-lasting performance.

Delrin in Various Industries

Delrin has been successfully applied across multiple industries, showcasing its versatility and reliability:

| Industry | Common Delrin Applications |

|---|---|

| Automotive | Bushings, gears, fuel system components |

| Medical Devices | Surgical tools, handles, fasteners |

| Consumer Electronics | Connectors, housing, precision gears |

| Industrial Equipment | Bearings, rollers, pulleys, conveyor system components |

| Aerospace | Structural components, low-friction bearings |

These applications demonstrate why Delrin continues to be a trusted material for CNC machined parts in a variety of settings.

The Benefits of CNC Machining Delrin: From Design to Production

Years of experience with CNC machining have shown that Delrin is exceptionally suited to this process. Its machinability is unmatched, making every step—from design to production—more efficient.

Ease of Machining

Delrin is incredibly easy to machine. It can be cut, drilled, milled, and turned without causing significant wear on cutting tools. This property reduces production time and lowers overall costs, making it an economical choice for custom parts.

Smooth Surface Finish

One of the standout features of Delrin is the smooth surface finish it delivers after machining. Parts often require little to no post-processing, which is a significant time saver. This smoothness is ideal for components that need low friction, such as gears and sliding parts.

Data Table: Surface Finish Comparison

| Material | Surface Finish Quality | Post-Processing Required | Suitability for Low Friction Parts |

|---|---|---|---|

| Delrin | Excellent | Minimal to None | High |

| Nylon | Good | Some Finishing Needed | Moderate |

| ABS | Moderate | Significant Finishing Needed | Low |

| Polycarbonate | Moderate | Some Finishing Needed | Low |

Delrin stands out for providing excellent surface finish quality with minimal finishing work required, making it ideal for precision parts.

Precision and Complexity

CNC machining allows for intricate designs and tight tolerances, and Delrin holds up well under these demands. The material’s stability ensures that complex parts maintain their exact measurements even after processing, making it a go-to material for custom jobs.

Delrin Part Applications: Customizing the Perfect Components

Throughout various CNC projects, Delrin has consistently proven to be a top choice for producing high-precision, durable components. Its versatility allows it to shine across multiple industries.

Gears and Bearings

Delrin’s low friction and wear resistance make it ideal for manufacturing custom gears and bearings. These parts run smoothly and are built to last, even under heavy loads.

Bushings and Spacers

In automotive and industrial sectors, Delrin’s durability makes it a prime choice for bushings and spacers. These components reduce vibration and improve the longevity of mechanical assemblies.

Medical Device Components

Delrin’s biocompatibility and ease of sterilization make it perfect for medical device components. Precision tools and diagnostic equipment benefit from Delrin’s ability to be machined with tight tolerances.

Data Table: Common CNC Machined Delrin Parts

| Component Type | Industry | Key Benefits |

|---|---|---|

| Gears | Automotive, Industrial | Low friction, high wear resistance |

| Bearings | Aerospace, Industrial | Durable under stress, precise fitting |

| Bushings | Automotive | Reduces vibration, wear-resistant |

| Surgical Tools | Medical | Biocompatible, easy to sterilize |

| Rollers | Manufacturing | Smooth operation, low friction |

These examples highlight how Delrin delivers excellent results in precision applications.

Key Factors in Choosing a CNC Supplier for Delrin Machining

Choosing the right CNC supplier is critical to ensuring the quality of custom Delrin parts. Based on past experiences, several key factors should be considered.

Machining Precision

Precision is everything when it comes to machining Delrin. A supplier experienced with Delrin will know how to maintain tight tolerances without causing material distortion or surface defects.

Lead Times and Production Capacity

Timely delivery is another essential factor. It’s important to find a supplier who can meet deadlines and has the capacity to handle both prototype and large production runs.

Design Support

A good CNC supplier should offer design support to optimize the part for manufacturing. This includes selecting the right tools, refining the design for manufacturability, and choosing appropriate machining techniques.

Cost Control

While quality is crucial, cost control is also important. Finding a CNC supplier who can deliver high-quality parts within a reasonable budget is essential for managing overall production costs.

Delrin vs. Other Plastics: Why Delrin Outperforms in CNC Machining

In the world of CNC machining, Delrin consistently outshines other plastics in terms of mechanical properties, ease of machining, and durability.

Delrin vs. Nylon

Nylon is another commonly used material, but Delrin offers superior dimensional stability and machinability. Nylon tends to absorb moisture, which can lead to swelling and reduced precision, whereas Delrin remains stable even in humid environments.

Delrin vs. ABS

ABS is often used for low-cost parts, but Delrin surpasses it in strength and wear resistance. ABS parts typically require more finishing work after machining, whereas Delrin parts come off the CNC machine with a smooth surface and tighter tolerances.

Data Table: Delrin vs. Other Plastics

| Property | Delrin | Nylon | ABS | Polycarbonate |

|---|---|---|---|---|

| Strength | High | Moderate | Low | High |

| Dimensional Stability | Excellent | Moderate | Low | Moderate |

| Ease of Machining | Excellent | Good | Moderate | Moderate |

| Moisture Absorption | Low | High | Low | Low |

| Surface Finish Quality | Excellent | Good | Moderate | Good |

For projects requiring precision, durability, and ease of machining, Delrin consistently proves to be the superior choice.

How CNC Machining Delrin Optimizes Product Design

CNC machining has allowed for greater flexibility in product design, and Delrin plays a key role in optimizing the process.

Custom Prototypes

CNC machining Delrin enables rapid production of prototypes, allowing for tight tolerance testing and validation before moving to full-scale production.

Complex Geometries

The machinability of Delrin allows for the creation of complex geometries that wouldn’t be achievable with other methods. CNC technology enables intricate designs while maintaining material stability.

Cost Analysis of CNC Machining Delrin Parts: Custom, Efficient, and Economical

Delrin offers a cost-effective solution for custom CNC machined parts due to its machinability and durability. Here’s a breakdown of what makes it an economical choice.

Material Costs

Delrin is competitively priced compared to other engineering plastics, making it a budget-friendly option for custom parts. Its machinability reduces overall production costs.

Machining Costs

Delrin’s ease of machining shortens CNC machining times, lowering labor costs. Its low wear on cutting tools also means reduced tool replacement expenses.

Data Table: Cost Factors for CNC Machining Delrin

| Cost Factor | Delrin | Nylon | ABS | Polycarbonate |

|---|---|---|---|---|

| Material Cost | Moderate | Low | Low | High |

| Machining Speed | Fast | Moderate | Moderate | Moderate |

| Tool Wear | Low | Moderate | Low | High |

| Post-Processing Cost | Low | Moderate | High | Moderate |

Delrin consistently proves to be a cost-effective and reliable choice for CNC machining projects.

Conclusion

Delrin is the ideal material for CNC machined parts, offering high strength, wear resistance, dimensional stability, and machinability

. It’s an excellent choice for producing custom components across a wide range of industries, from automotive to medical devices. Whether creating gears, bushings, or surgical tools, Delrin delivers the precision and durability needed for high-performance applications. For anyone looking for a reliable material for CNC machining, Delrin stands out as the top choice.

FAQ

1. What makes Delrin a better choice than other plastics for CNC machining?

Delrin offers superior machinability, strength, and wear resistance, making it ideal for applications where precision and durability are critical.

2. Can Delrin parts be used in high-stress applications?

Yes, Delrin performs exceptionally well under stress, making it suitable for gears, bearings, and other high-load components.

3. How does Delrin compare to metals in terms of CNC machining?

While not as strong as metals, Delrin offers significant advantages such as being lightweight, corrosion-resistant, and easier to machine, making it a great alternative for non-metallic parts.

4. What industries benefit most from CNC machined Delrin parts?

Industries like automotive, medical devices, aerospace, and consumer electronics benefit from Delrin’s low friction, dimensional stability, and strength.

5. Is CNC machining Delrin cost-effective for small production runs?

Yes, CNC machining Delrin is cost-effective for both small and large production runs due to its ease of machining and minimal post-processing requirements.

Other Articles You Might Enjoy

- Delrin in CNC Machining: The Ultimate Guide for Engineers

Introduction to Delrin and Its Role in CNC Machining Delrin, a high-performance engineering plastic, has become a cornerstone material for industries relying on precision machining. This polyoxymethylene homopolymer (POM-H) is…

- How CNC Machining Delivers Precision in Custom POM Plastic Parts

Working with POM plastic in CNC machining has become a popular choice for manufacturers due to its excellent mechanical properties, low friction, and high dimensional stability. Customizing parts using this…

- Delrin Material Introduction and Its Precision Machining Applications

Introduction to Delrin Material Delrin, also known as POM-H (Polyoxymethylene Homopolymer), is a high-performance engineering thermoplastic. It is widely used in precision machining, 3D printing, and injection molding due to…

- CNC Machined Plastic Parts: An In-depth Overview(CNC machined plastic parts Norman)

Computer Numeric Control (CNC) machining is an advanced manufacturing process where pre-programmed software dictates the movement of factory machinery and tools. These applications can carry out complicated manufacturing tasks with…

- Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the…

- Impact of Surface Roughness on CNC Machined Parts: Material and Process Variables

Introduction to CNC Machining and Surface Roughness CNC machining, abbreviated from Computer Numerical Control machining, is a manufacturing technique that uses pre-written computer software for dictating the movement of factory…

- Strategies for Enhancing Thermal Conductivity in CNC Machined Parts

The Importance of Thermal Conductivity in CNC Machined Parts In the sphere of CNC machining, thermal conductivity is an extremely vital factor. It has crucial effects on both performance and…

- Brittleness, a key material factor affecting the strength of CNC-machined parts

Definition and Importance of Brittleness in Materials Science In materials science, brittleness refers to the tendency of a material to fracture or shatter upon impact or under stress without significant…