What is a glitch

Small particles with protrusions on the surface of the workpiece, especially the edges, may have hook-like protrusions.

Causes of burrs

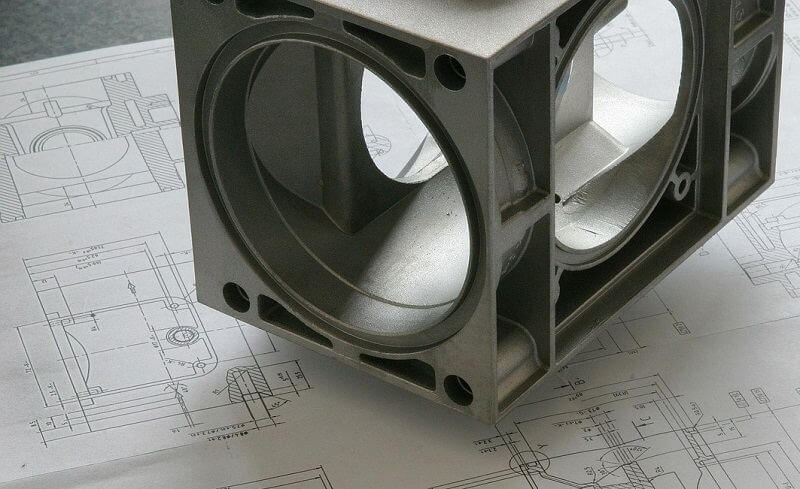

Metal materials have ductility, toughness, and plasticity, properties that cause metals to deform unevenly during CNC machining. Ductility, in particular, acts to stop cutting and cause burrs on escaped parts.

Solutions

1.Tool review

Check whether the tool is sharp and hard enough, and adjust the contact angle of the tool during machining to improve the effectiveness of cutting.

2.Cutting oil

When the tool is cutting, heat will be generated due to friction, and if the heat is not dissipated in time, the cutting may not be smooth and deformed. Therefore, cutting oil is generally sprayed at present. Wet machining is less prone to burrs than dry machining, and properties such as oil amount and viscosity also affect it.

3.Load adjustment

The load of the tool will change due to the deformation of the material, the speed of the tool and the depth of cut, and it needs to be adjusted if necessary.

4.Design

For example, rounded corners are less prone to burrs than right angles, so it is a good idea to avoid right angles if possible.

5.Deburring

If burrs cannot be avoided due to the nature of the material or processing, deburring (grinding, polishing, sandblasting, etc.) is performed after processing. In addition, deburring programs can be added for CNC machines and multitasking machines.

Other Articles You Might Enjoy

- Precision CNC Machining Service: High-Quality Titanium Parts

Precision CNC Machining Service: High-Quality Titanium Parts In the world of manufacturing, precision Computer Numerical Control (CNC) machining plays a pivotal role. This technology-driven process utilizes pre-programmed software to regulate…

- Innovative CNC Machining for Complex Surgical Tools

Introduction to CNC Machining and its Significance in Surgical Tools Manufacturing CNC machining, an acronym for Computer Numerical Control machining, plays a significant role in the manufacturing world. Being an…

- Applications and Advantages of Bronze CNC Machining

1. Introduction: The Enduring Allure of Bronze in CNC Machining In this opening section, we explore the timeless appeal of bronze as a material for CNC machining. From its rich…