In CNC machining, the accuracy and efficiency of the final product often hinge on the initial planning and calculations. One of the critical steps in this process is creating detailed workpiece sketches and performing precise mathematical calculations. Let’s dive into how these elements contribute to successful CNC machining and how they can be optimized.

The Importance of Workpiece Sketching

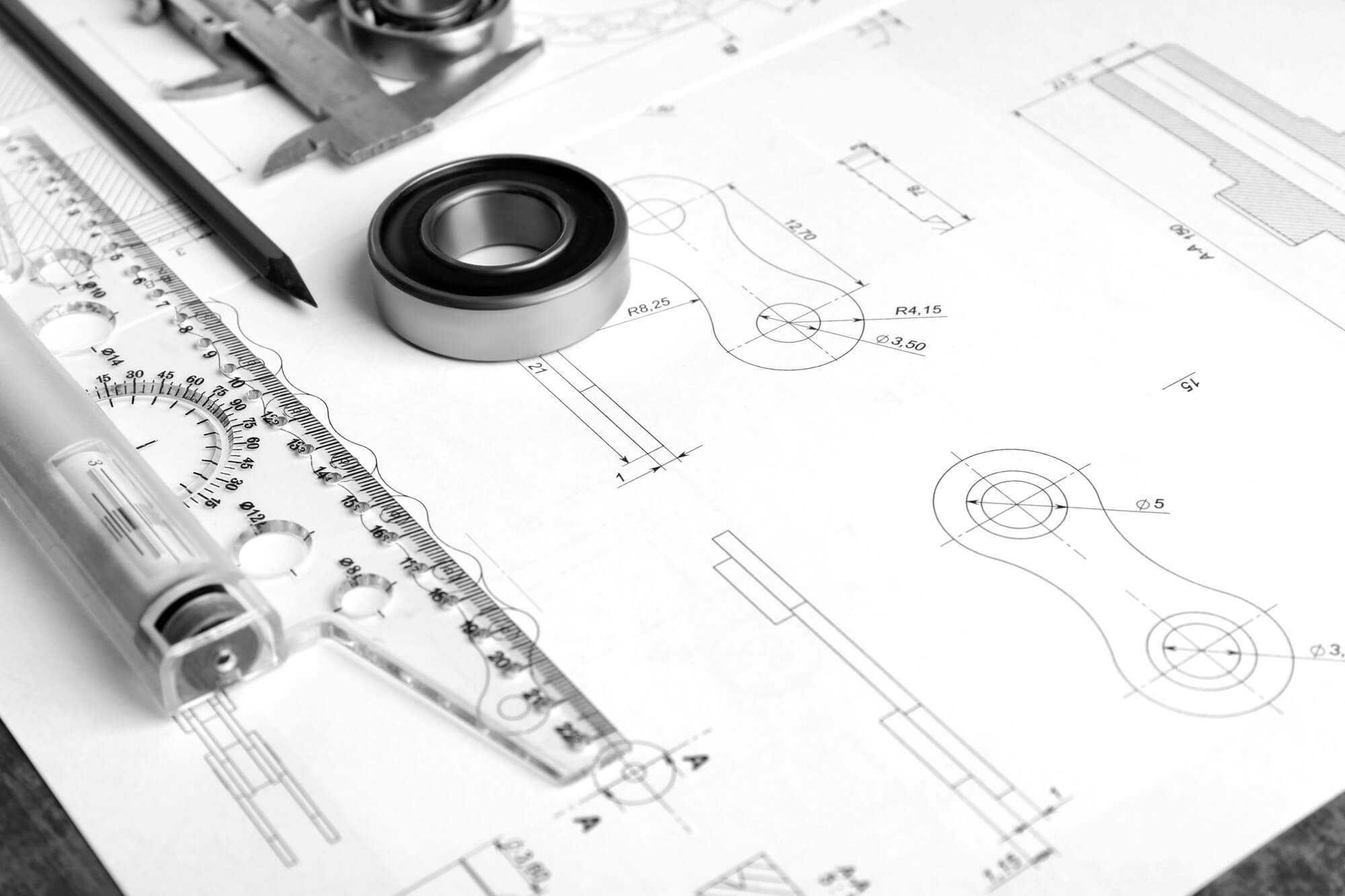

Creating a workpiece sketch is more than just drawing a rough outline of the part to be machined. It’s about visualizing the final product, understanding the relationship between different features, and planning the machining process. A well-done sketch helps in identifying potential issues early and provides a clear roadmap for the machining operations.

Benefits of Workpiece Sketching:

- Visual Clarity: Sketches provide a visual representation of the part, making it easier to understand the machining process.

- Precision: Detailed sketches help in ensuring that all dimensions and tolerances are accurately captured.

- Problem Solving: Early identification of potential issues allows for adjustments before the machining begins, saving time and resources.

Creating Effective Workpiece Sketches

To create an effective workpiece sketch, follow these steps:

- Use a Large Scale: Drawing the sketch to a larger scale makes it easier to include all necessary details and visualize the relationships between different features.

- Include All Dimensions: Ensure that all critical dimensions and tolerances are marked clearly. This includes lengths, widths, depths, and angles.

- Highlight Key Features: Use color coding or different symbols to highlight important features such as holes, slots, and surface finishes.

- Avoid Guesswork: Never rely on scaled drawings for dimensions. Always use precise measurements.

Mathematical Calculations in CNC Programming

Mathematical calculations are at the heart of CNC programming. They ensure that the tool paths are accurate, the cutting parameters are optimal, and the final product meets the design specifications.

Key Mathematical Concepts:

- Arithmetic and Algebra: Basic arithmetic and algebra are used for calculating dimensions, positions, and offsets.

- Trigonometry: Trigonometry helps in determining angles and distances in complex shapes.

- Geometry: Understanding geometric relationships is crucial for creating accurate tool paths.

- Advanced Mathematics: For complex shapes like molds and dies, knowledge of calculus and spherical trigonometry might be necessary.

Common Calculations in CNC Programming

- Tool Path Calculation: Determining the exact path the tool will take to machine the part. This includes calculating coordinates for linear and circular interpolation.

- Cutting Speed and Feed Rate: Calculating the optimal spindle speed and feed rate based on the material and tool being used.

- Cutting Depth: Determining the appropriate depth of cut to balance efficiency and tool life.

Practical: Sketching and Calculating for a Complex Part

Consider a complex part that requires multiple operations, such as milling and drilling. Here’s how you can approach the sketching and calculation process:

- Initial Sketch: Create a detailed sketch of the part with all critical dimensions. Use a large scale to ensure clarity.

- Identify Key Features: Highlight features such as holes, slots, and complex contours. Use different colors or symbols for easy identification.

- Calculate Tool Paths: Use trigonometry to calculate the coordinates for each tool path. Ensure that the tool will move smoothly between points without causing collisions.

- Determine Cutting Parameters: Calculate the spindle speed, feed rate, and cutting depth based on the material and tool. Use the following formulas as a guide: Spindle Speed (RPM)=π×Tool DiameterCutting /Speed×1000

Using Coordinate Cards

Coordinate cards are a practical tool for organizing the results of your calculations. Each card lists the coordinates of critical points in the tool path. This method ensures that all necessary data is easily accessible during programming.

| Position | X Coordinate | Y Coordinate | Z Coordinate |

|---|---|---|---|

| Start | 0.0 | 0.0 | 0.0 |

| P1 | 10.0 | 15.0 | 0.0 |

| P2 | 20.0 | 30.0 | 0.0 |

| P3 | 30.0 | 45.0 | 0.0 |

| End | 40.0 | 60.0 | 0.0 |

Workpiece sketching and precise calculations are fundamental to successful CNC machining. By taking the time to create detailed sketches and perform accurate mathematical calculations, machinists can ensure high-quality, efficient, and error-free production. Whether working with simple parts or complex assemblies, these skills are invaluable for optimizing the machining process.

Other Articles You Might Enjoy

- The main factors of workpiece deformation in CNC machining

With the rapid development of science and technology, many fields have already reached a near-saturated state. The market competition in the field of CNC machining is becoming more and more…

- What are the requirements for CNC machining of bearing parts?

Bearings are common and important parts in the automotive industry, which can support transmission components and transmit torque. Generally, CNC machining centers are used to process bearing parts. So what…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Evolution of Mills and Machining Centers: The Future of CNC Machining Parts

Stepping into the world of CNC machining, you quickly realize how pivotal mills and machining centers are in crafting precise parts. Over time, these machines have evolved significantly, transforming from…

- Aluminum CNC Machining Service for Custom Parts

Aluminum CNC machining stands at the forefront of modern manufacturing, epitomizing precision, versatility, and efficiency. With its widespread applications across industries ranging from aerospace to automotive and beyond, aluminum CNC…

- Smart Choice for CNC Machining Parts: Comprehensive Analysis of Horizontal Machining Centers

When it comes to CNC machining parts, the type of machining center you choose can significantly impact the efficiency and quality of your work. Horizontal CNC machining centers (HMCs) are…